1. Disconnect sander from power source.

2. Loosen the lower hex nut (A, Figure 11/12) on the motor base.

3. Tighten the top hex nut (B, Figure 11/12) to lower the motor plate until proper tension is achieved.

4. When the belt is properly tensioned, you should be able to push in the belt approximately 3/4” at a point midway between the pulleys using moderate finger pressure.

5.

If installing a new

NOTE: When replacing

9.7 Conveyor Belt Tension

Check the tension of the conveyor belt on the infeed and outfeed rollers – the conveyor belt should be tight enough that you cannot shift it with your hands. If the conveyor belt needs tightening, proceed as follows.

1. | Disconnect sander from power source. |

|

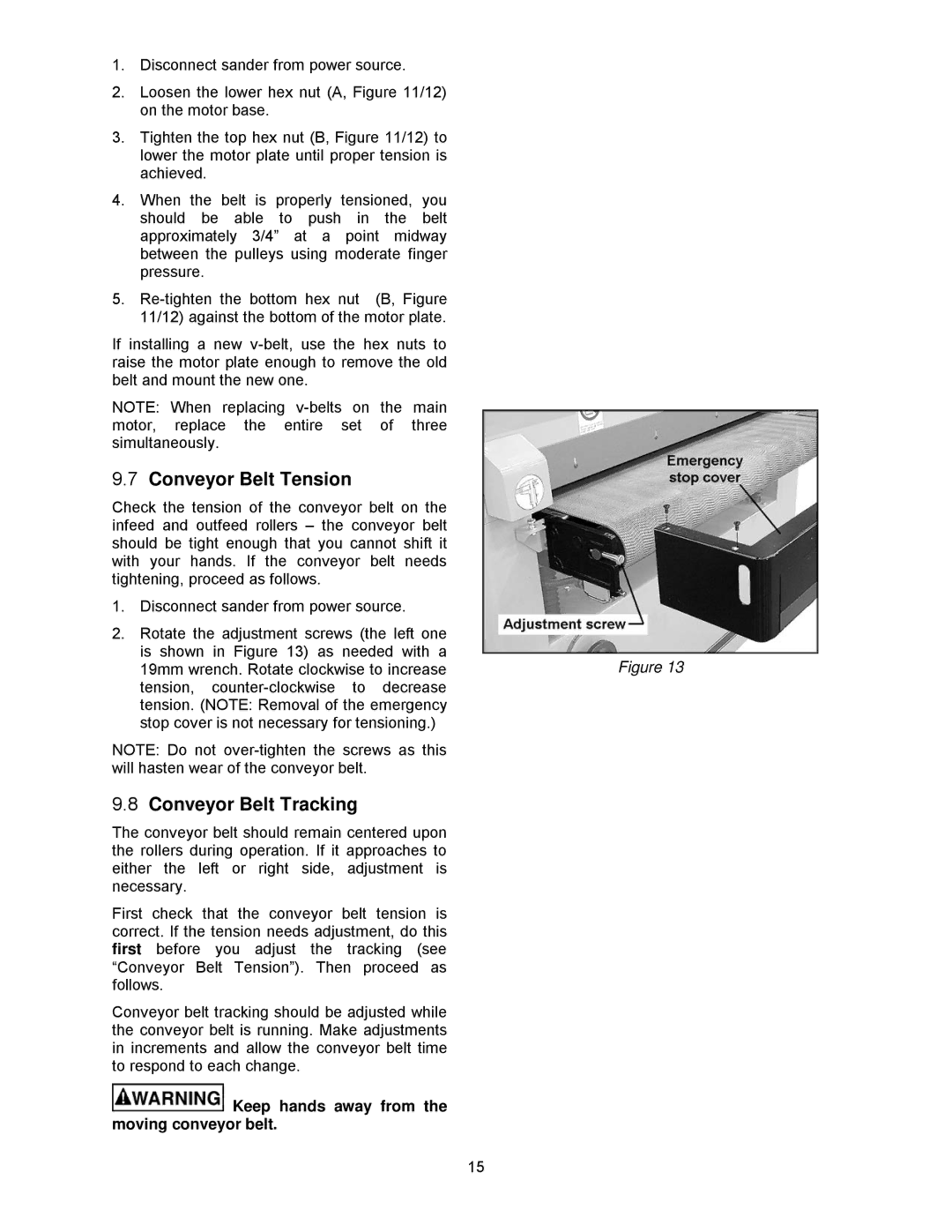

2. | Rotate the adjustment screws (the left one |

|

| is shown in Figure 13) as needed with a | Figure 13 |

| 19mm wrench. Rotate clockwise to increase | |

| tension, |

|

| tension. (NOTE: Removal of the emergency |

|

| stop cover is not necessary for tensioning.) |

|

NOTE: Do not |

| |

will hasten wear of the conveyor belt. |

| |

9.8 Conveyor Belt Tracking

The conveyor belt should remain centered upon the rollers during operation. If it approaches to either the left or right side, adjustment is necessary.

First check that the conveyor belt tension is correct. If the tension needs adjustment, do this first before you adjust the tracking (see “Conveyor Belt Tension”). Then proceed as follows.

Conveyor belt tracking should be adjusted while the conveyor belt is running. Make adjustments in increments and allow the conveyor belt time to respond to each change.

Keep hands away from the moving conveyor belt.

Keep hands away from the moving conveyor belt.

15