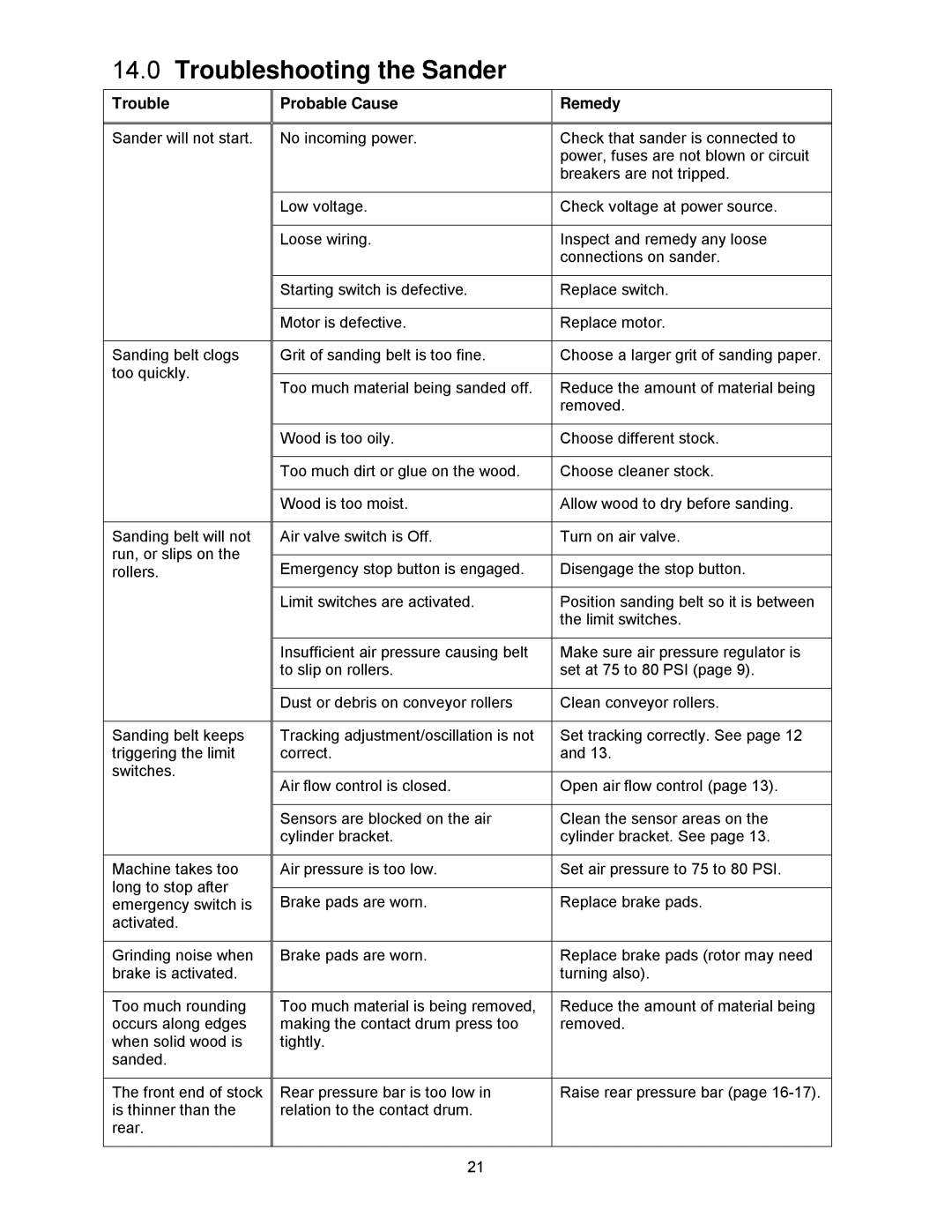

14.0Troubleshooting the Sander

Trouble

Sander will not start.

Sanding belt clogs too quickly.

Sanding belt will not run, or slips on the rollers.

Sanding belt keeps triggering the limit switches.

Machine takes too long to stop after emergency switch is activated.

Grinding noise when brake is activated.

Too much rounding occurs along edges when solid wood is sanded.

The front end of stock is thinner than the rear.

Probable Cause | Remedy |

|

|

No incoming power. | Check that sander is connected to |

| power, fuses are not blown or circuit |

| breakers are not tripped. |

|

|

Low voltage. | Check voltage at power source. |

|

|

Loose wiring. | Inspect and remedy any loose |

| connections on sander. |

|

|

Starting switch is defective. | Replace switch. |

|

|

Motor is defective. | Replace motor. |

|

|

Grit of sanding belt is too fine. | Choose a larger grit of sanding paper. |

|

|

Too much material being sanded off. | Reduce the amount of material being |

| removed. |

|

|

Wood is too oily. | Choose different stock. |

|

|

Too much dirt or glue on the wood. | Choose cleaner stock. |

|

|

Wood is too moist. | Allow wood to dry before sanding. |

|

|

Air valve switch is Off. | Turn on air valve. |

|

|

Emergency stop button is engaged. | Disengage the stop button. |

|

|

Limit switches are activated. | Position sanding belt so it is between |

| the limit switches. |

|

|

Insufficient air pressure causing belt | Make sure air pressure regulator is |

to slip on rollers. | set at 75 to 80 PSI (page 9). |

|

|

Dust or debris on conveyor rollers | Clean conveyor rollers. |

|

|

Tracking adjustment/oscillation is not | Set tracking correctly. See page 12 |

correct. | and 13. |

|

|

Air flow control is closed. | Open air flow control (page 13). |

|

|

Sensors are blocked on the air | Clean the sensor areas on the |

cylinder bracket. | cylinder bracket. See page 13. |

|

|

Air pressure is too low. | Set air pressure to 75 to 80 PSI. |

|

|

Brake pads are worn. | Replace brake pads. |

|

|

Brake pads are worn. | Replace brake pads (rotor may need |

| turning also). |

|

|

Too much material is being removed, | Reduce the amount of material being |

making the contact drum press too | removed. |

tightly. |

|

|

|

Rear pressure bar is too low in | Raise rear pressure bar (page |

relation to the contact drum. |

|

|

|

21