model WB-37 shown

Powermatic

Models WB-25, WB-37, WB-43

Part No. M-1790825

What is Covered

1.0 Warranty and Service

Warranty Period

Warranty Limitations

2.0 Table of Contents

Section

16.8.1 Pressure Bar Assembly - Models WB-25, WB-37, WB-43

3.0 Safety warnings

SAVE THESE INSTRUCTIONS

3.0 Safety warnings

Table Height from Floor in

5.0 Specifications

4.0 Introduction

Dust Ports

6.1 Contents of Shipping Container

6.0 Unpacking

7.1 Air Supply Connection

7.0 Assembly

7.2 Dust Collection

8.0 Electrical

7.3 Installing/Replacing Sanding Belt

8.1 Grounding Instructions

8.2 230 Volt Operation

Model WB-25 shown

8.4 Extension cords

9.0 Adjustments

8.3 460 Volt Conversion

9.1 Sanding Belt Tracking and Oscillation

9.2 Oscillation Air Flow

9.3 Oscillation Speed

9.4 Platen Position

9.6 V-Belt Tension and Replacement

9.5 Replacing Graphite and Felt Pad

9.8 Conveyor Belt Tracking

9.7 Conveyor Belt Tension

Keep hands away from the moving conveyor belt

9.10 Pressure Bar Adjustment

9.9 Feed Rate

9.11 Table Parallelism

10.1 Amperage Meter

10.0 Operating Controls

10.2 LED Controller and Keypad

10.2.2 Using the LED for Operations

11.0 Operation

11.1 Braking System

10.2.1 Calibration

12.0 Maintenance

13.0 Dust Port Layout

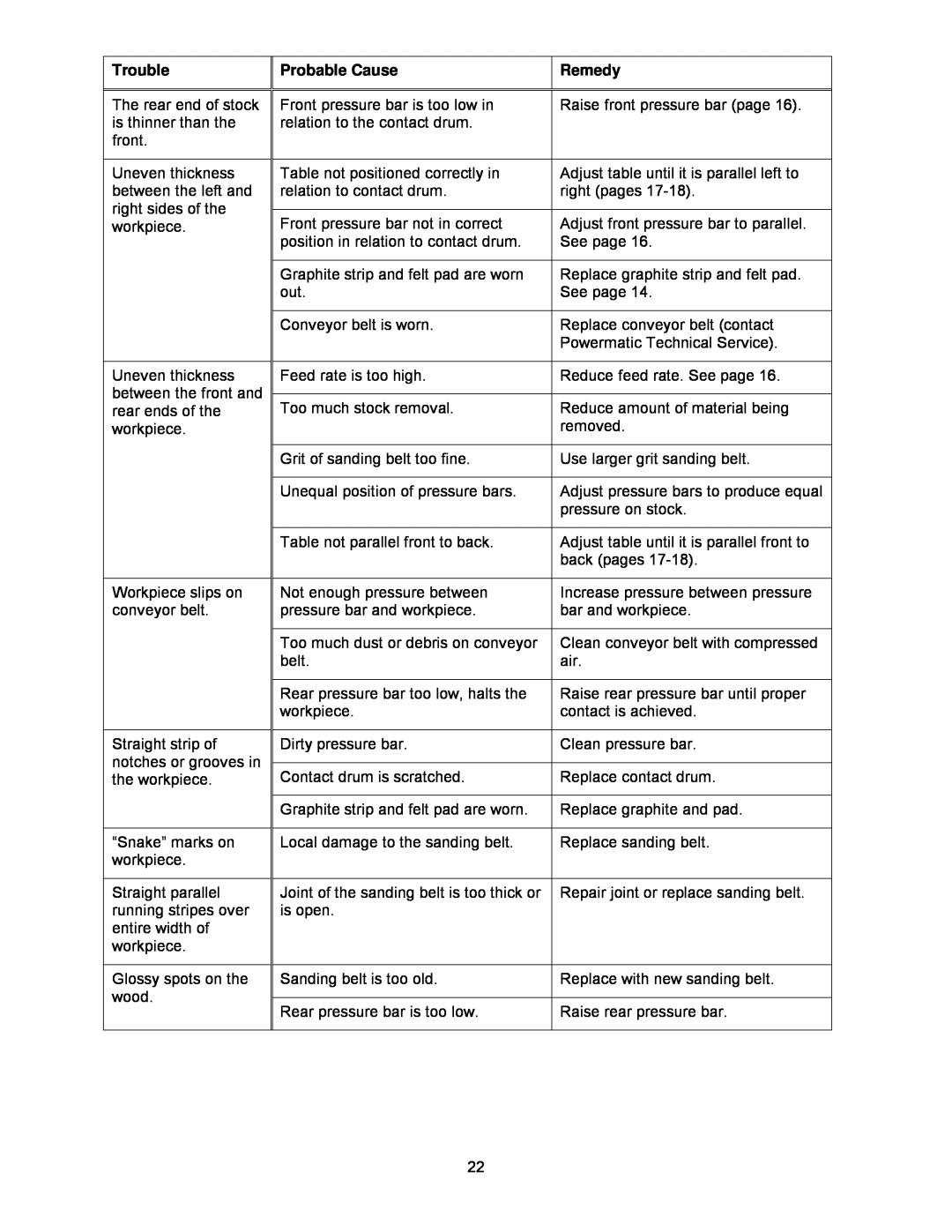

Probable Cause

14.0 Troubleshooting the Sander

Trouble

Remedy

Probable Cause

Trouble

Remedy

Trouble

15.0 Troubleshooting the LED Unit

16.0 Replacement Parts

Probable Cause

16.1.1 Base and Motor Assembly - Model WB-25 ONLY

Parts list on page

Description

16.1.2 Parts List Base and Motor Assembly - Model WB-25

Index No. Part No

Size

16.2.1 Base and Motor Assembly - Model WB-37 ONLY

Parts list on page

Description

16.2.2 Parts List Base and Motor Assembly - Model WB-37

Index No. Part No

Size

16.3.1 Base and Motor Assembly - Model WB-43 ONLY

Parts list on page

Description

16.3.2 Parts List Base and Motor Assembly - Model WB-43

Index No. Part No

Size

16.4.1 Upper Cabinet Assembly - Model WB-25 ONLY

Parts list on page

Description

16.4.2 Parts List Upper Cabinet Assembly - Model WB-25

Index No. Part No

Size

16.5.1 Upper Cabinet Assembly - Models WB-37, WB-43

Parts list on page

Index No. Part No

16.5.2 Parts List Upper Cabinet Assembly - Model WB-37

16.5.3 Parts List Upper Cabinet Assembly - Model WB-43

Description

16.6.1 Table Raising Assembly - Models WB-25, WB-37, WB-43

Parts list on page 35 WB-25, page 36 WB-37 and page 37 WB-43

Description

16.6.2 Parts List Table Raising Assembly - Model WB-25

Index No. Part No

Size

Description

16.6.3 Parts List Table Raising Assembly - Model WB-37

Index No. Part No

Size

Description

16.6.4 Parts List Table Raising Assembly - Model WB-43

Index No. Part No

Size

6294333

16.7.1 Table and Conveyor Belt Assembly - Models WB-25, WB-37, WB-43

Parts list on page 40 WB-25, page 41 WB-37 and page 42 WB-43

Description

16.7.2 Parts List Table and Conveyor Belt Assembly - Model WB-25

Index No. Part No

Size

Description

16.7.3 Parts List Table and Conveyor Belt Assembly - Model WB-37

Index No. Part No

Size

Description

16.7.4 Parts List Table and Conveyor Belt Assembly - Model WB-43

Index No. Part No

Size

Index No. Part No

16.8.1 Pressure Bar Assembly - Models WB-25, WB-37, WB-43

16.8.2 Parts List Pressure Bar Assembly - Model WB-25

Description

Index No. Part No

16.8.3 Parts List Pressure Bar Assembly - Model WB-37

16.8.4 Parts List Pressure Bar Assembly - Model WB-43

Description

Index No. Part No

16.9.1 Platen Assembly - Model WB-25 only

16.9.2 Parts List Platen Assembly - Model WB-25

Description

Description

Index No. Part No

Size

Index No. Part No

16.10.1 Platen Assembly - Models WB-37, WB-43

16.10.2 Parts List Platen Assembly - Model WB-37

Description

Description

16.10.3 Parts List Platen Assembly - Model WB-43

Index No. Part No

Size

TS-0060061

Index No. Part No

16.11.1 Air Regulator Assembly - Models WB-25, WB-37, WB-43

16.11.2 Parts List Air Regulator Assembly - Model WB-25

Description

Description

16.11.3 Parts List Air Regulator Assembly - Model WB-37

Index No. Part No

Size

Description

16.11.4 Parts List Air Regulator Assembly - Model WB-43

Index No. Part No

Size

16.12.1 Sanding Belt and Accessories - Models WB-25, WB-37, WB-43

Parts list on page

16.12.4 Parts List Sanding Belt and Accessories - Model WB-43

16.12.2 Parts List Sanding Belt and Accessories - Model WB-25

16.12.3 Parts List Sanding Belt and Accessories - Model WB-37

Index No. Part No

16.13.1 Tension Roller Assembly - Models WB-25 and WB-37 ONLY

Parts list on page 56 WB-25 and page 57 WB-37

Description

16.13.2 Parts List Tension Roller Assembly - Model WB-25

Index No. Part No

Size

Description

16.13.3 Parts List Tension Roller Assembly - Model WB-37

Index No. Part No

Size

Size

Index No. Part No

Description

WB25-149

16.14.1 Tension Roller Assembly - Model WB-43 ONLY

Parts list on page

Description

16.14.2 Parts List Tension Roller Assembly - Model WB-43

Index No. Part No

Size

Size

Index No. Part No

Description

WB43-163

16.15.1 Electrical Box Assembly - Models WB-25 and WB-37

Parts list on page 63 WB-25 and 64 WB-37

Description

16.15.2 Parts List Electrical Box Assembly - Model WB-25

Index No. Part No

Size

Description

16.15.3 Parts List Electrical Box Assembly - Model WB-37

Index No. Part No

Size

16.16.1 Electrical Box Assembly - Model WB-43 ONLY

Parts list on page

Description

16.16.2 Parts List Electrical Box Assembly - Model WB-43

Index No. Part No

Size

17.0 Electrical Connections

17.1 Models WB-25 and WB-37 ONLY

17.2 Model WB-43 ONLY