Install Cable Cover

Check the bottom view of the printer, the 4 screws for the printer itself are in quite deep holes. Insert the tenons of the cable cover into the 2 printer screw holes nearest to the connection area. Apply a cable cover fixing screw at the matched screw holes as circled in the bottom view picture at right.

Power On

When all the above cable connections are made correctly, you may connect your power adaptor to the wall outlet. Make sure that the type of power cord and

the voltage requirement of the power adaptor meet the local power conditions. Now the printer is ready for power on.

Self Test

Press and hold down the feed button while turning the on / off switch on. The printer will then perform a

The header is printed in text mode and the rest part of this slip is printed in page mode. If FEED button is pressed at this moment, a font table will be printed in text mode again. To exit the test printing, please turn the printer off and on again.

SPECIAL ADJUSTMENTS

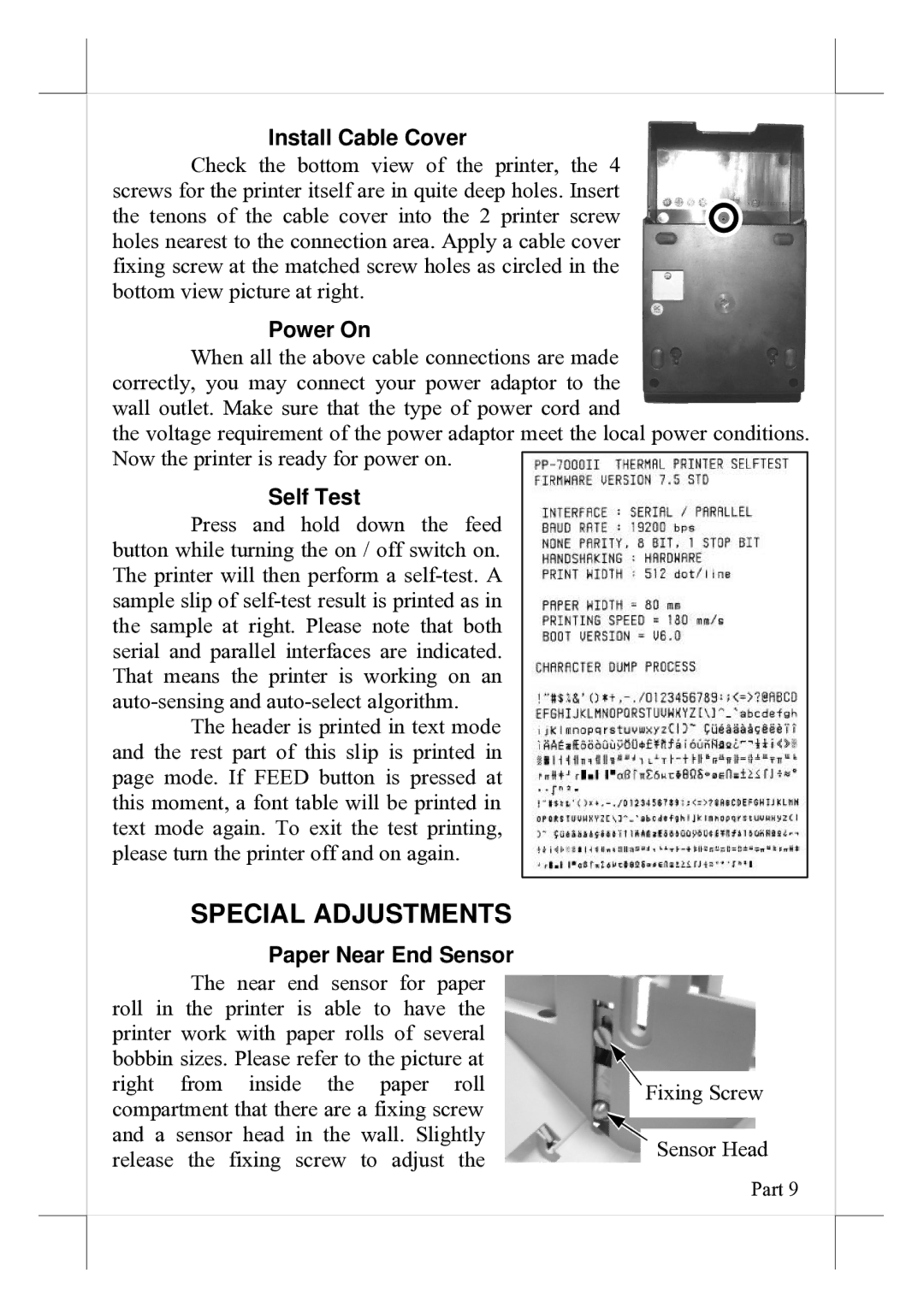

Paper Near End Sensor

The near end sensor for paper roll in the printer is able to have the printer work with paper rolls of several bobbin sizes. Please refer to the picture at right from inside the paper roll compartment that there are a fixing screw and a sensor head in the wall. Slightly release the fixing screw to adjust the

Fixing Screw

Sensor Head

Part 9