speed. Do not operate summer exhaust fan. Close fireplace dampers.

4.Place in operation the appliances being inspected. Follow the manufacturer’s instructions for lighting each appliance. Adjust thermostat so appliance will operate continuously.

5.Check the pressure at a pressure tap located 12 in. above the bottom joint of the first vertical vent pipe. Pressure should be anywhere between

6.After it has been determined that each appliance remaining connected to the common venting sys- tem properly vents when tested as outlined above, return doors, windows, exhaust fans, fireplace dampers and other gas burning appliances to their previous conditions of use.

7.Any improper operation of the common venting system should be corrected so that the installation conforms with the NFGC (U.S.) or B149 (Canada). When

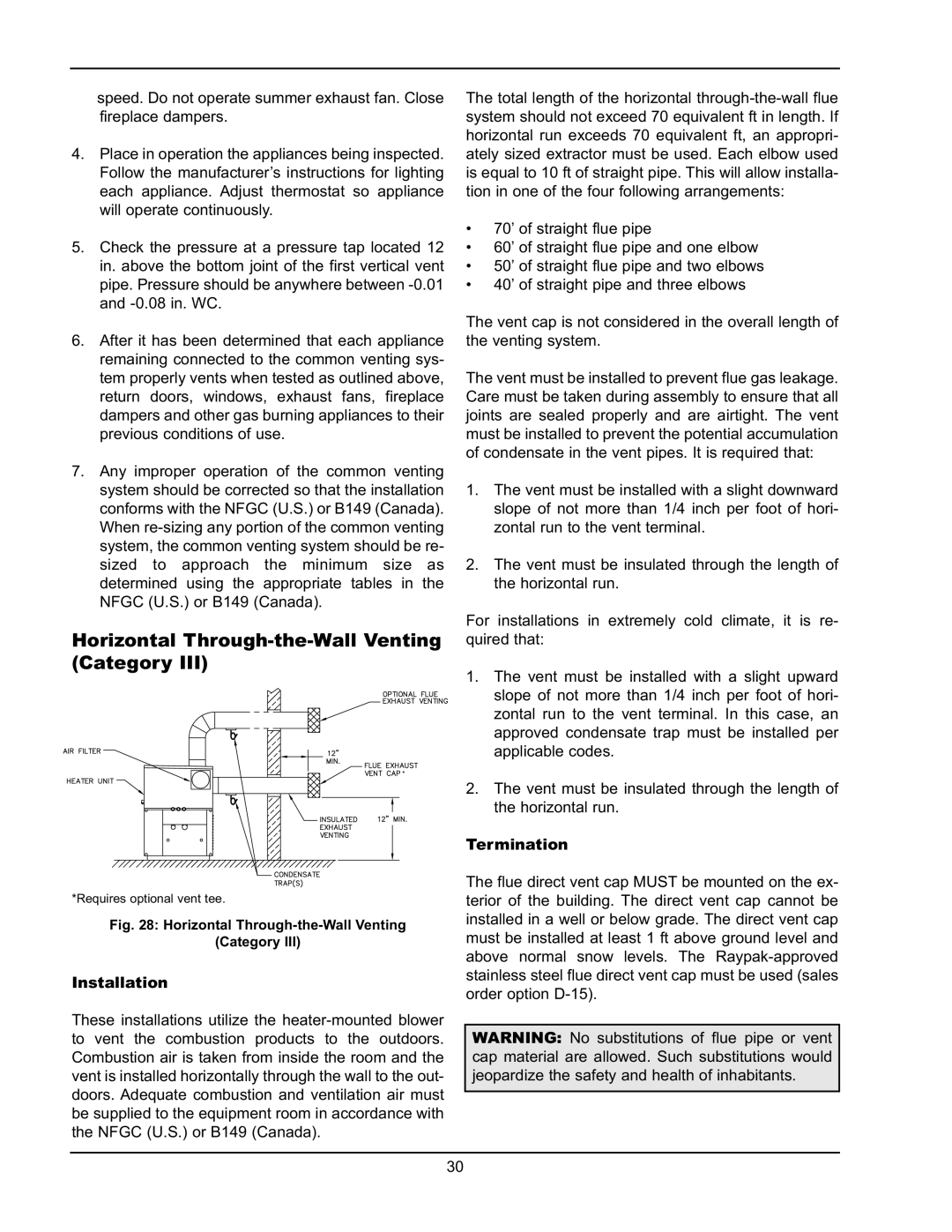

Horizontal Through-the-Wall Venting (Category III)

*

*Requires optional vent tee.

Fig. 28: Horizontal Through-the-Wall Venting

(Category III)

Installation

These installations utilize the

The total length of the horizontal

•70’ of straight flue pipe

•60’ of straight flue pipe and one elbow

•50’ of straight flue pipe and two elbows

•40’ of straight pipe and three elbows

The vent cap is not considered in the overall length of the venting system.

The vent must be installed to prevent flue gas leakage. Care must be taken during assembly to ensure that all joints are sealed properly and are airtight. The vent must be installed to prevent the potential accumulation of condensate in the vent pipes. It is required that:

1.The vent must be installed with a slight downward slope of not more than 1/4 inch per foot of hori- zontal run to the vent terminal.

2.The vent must be insulated through the length of the horizontal run.

For installations in extremely cold climate, it is re- quired that:

1.The vent must be installed with a slight upward slope of not more than 1/4 inch per foot of hori- zontal run to the vent terminal. In this case, an approved condensate trap must be installed per applicable codes.

2.The vent must be insulated through the length of the horizontal run.

Termination

The flue direct vent cap MUST be mounted on the ex- terior of the building. The direct vent cap cannot be installed in a well or below grade. The direct vent cap must be installed at least 1 ft above ground level and above normal snow levels. The

WARNING: No substitutions of flue pipe or vent cap material are allowed. Such substitutions would jeopardize the safety and health of inhabitants.

30