For installations in extremely cold climate, it is re- quired that:

1.The vent must be installed with a slight upward slope of not more than 1/4 inch per foot of hori- zontal run to the vent terminal. In this case, an approved condensate trap must be installed per applicable codes.

2.The intake vent must be insulated through the length of the horizontal run.

Termination

The flue direct vent cap MUST be mounted on the ex- terior of the building. The direct vent cap cannot be installed in a well or below grade. The direct vent cap must be installed at least 1 ft above ground level and above normal snow levels.

The direct vent cap MUST NOT be installed with any combustion air inlet directly above a direct vent cap. This vertical spacing would allow the flue products from the direct vent cap to be pulled into the combus- tion air intake installed above.

This type of installation can cause

Combustion air supplied from outdoors must be free of particulate and chemical contaminants. To avoid a blocked flue condition, keep the vent cap clear of snow, ice, leaves, debris, etc.

WARNING: No substitutions of flue pipe or vent cap material are allowed. Such substitutions would jeopardize the safety and health of inhabitants.

The stainless steel flue direct vent cap must be fur- nished by the heater manufacturer in accordance with its listing (sales order option

Use only the special gas vent pipes listed for use with Category III gas burning heaters, such as the

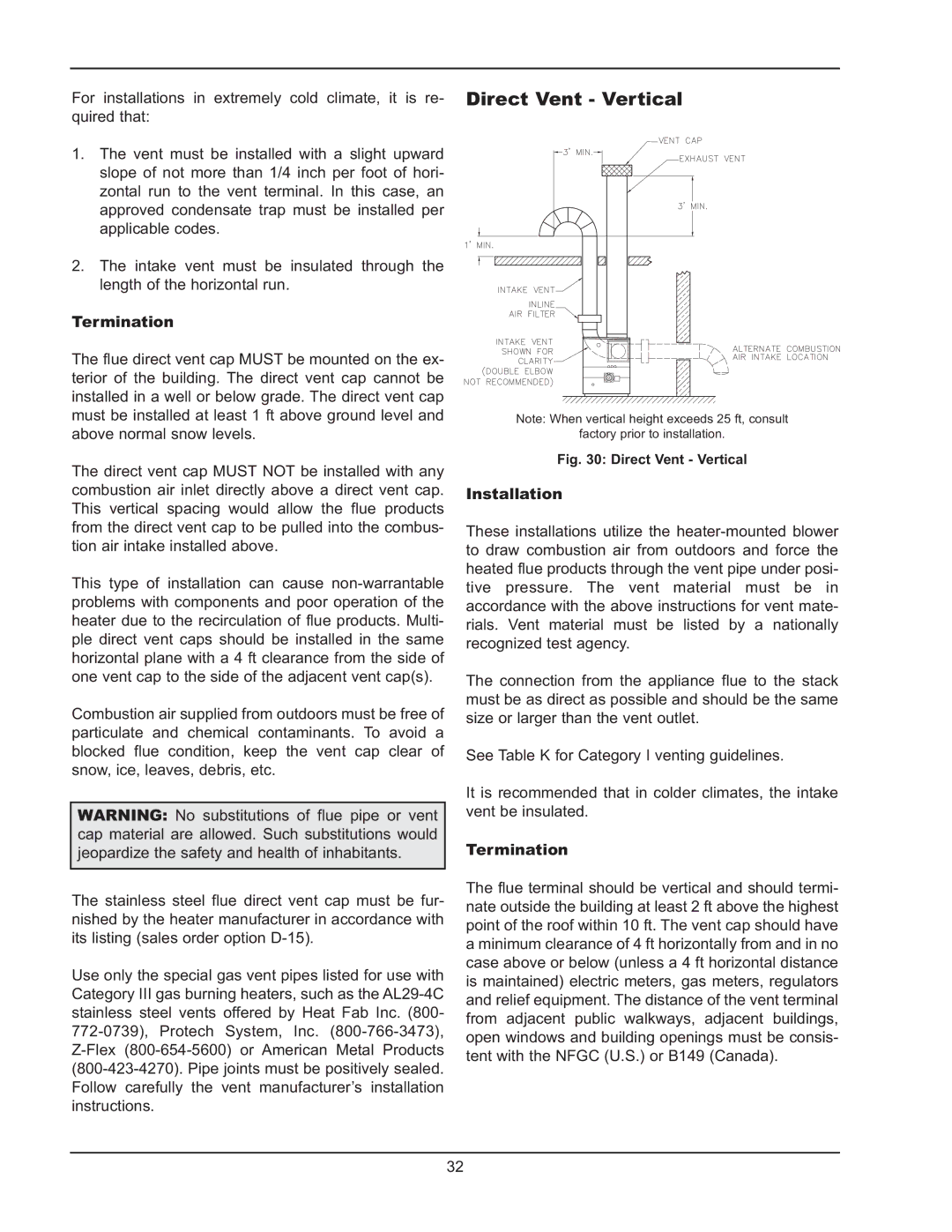

Direct Vent - Vertical

Note: When vertical height exceeds 25 ft, consult

factory prior to installation.

Fig. 30: Direct Vent - Vertical

Installation

These installations utilize the

The connection from the appliance flue to the stack must be as direct as possible and should be the same size or larger than the vent outlet.

See Table K for Category I venting guidelines.

It is recommended that in colder climates, the intake vent be insulated.

Termination

The flue terminal should be vertical and should termi- nate outside the building at least 2 ft above the highest point of the roof within 10 ft. The vent cap should have a minimum clearance of 4 ft horizontally from and in no case above or below (unless a 4 ft horizontal distance is maintained) electric meters, gas meters, regulators and relief equipment. The distance of the vent terminal from adjacent public walkways, adjacent buildings, open windows and building openings must be consis- tent with the NFGC (U.S.) or B149 (Canada).

32