The stainless steel direct vent cap must be furnished by the boiler manufacturer in accordance with its list- ing (sales order option

Use only

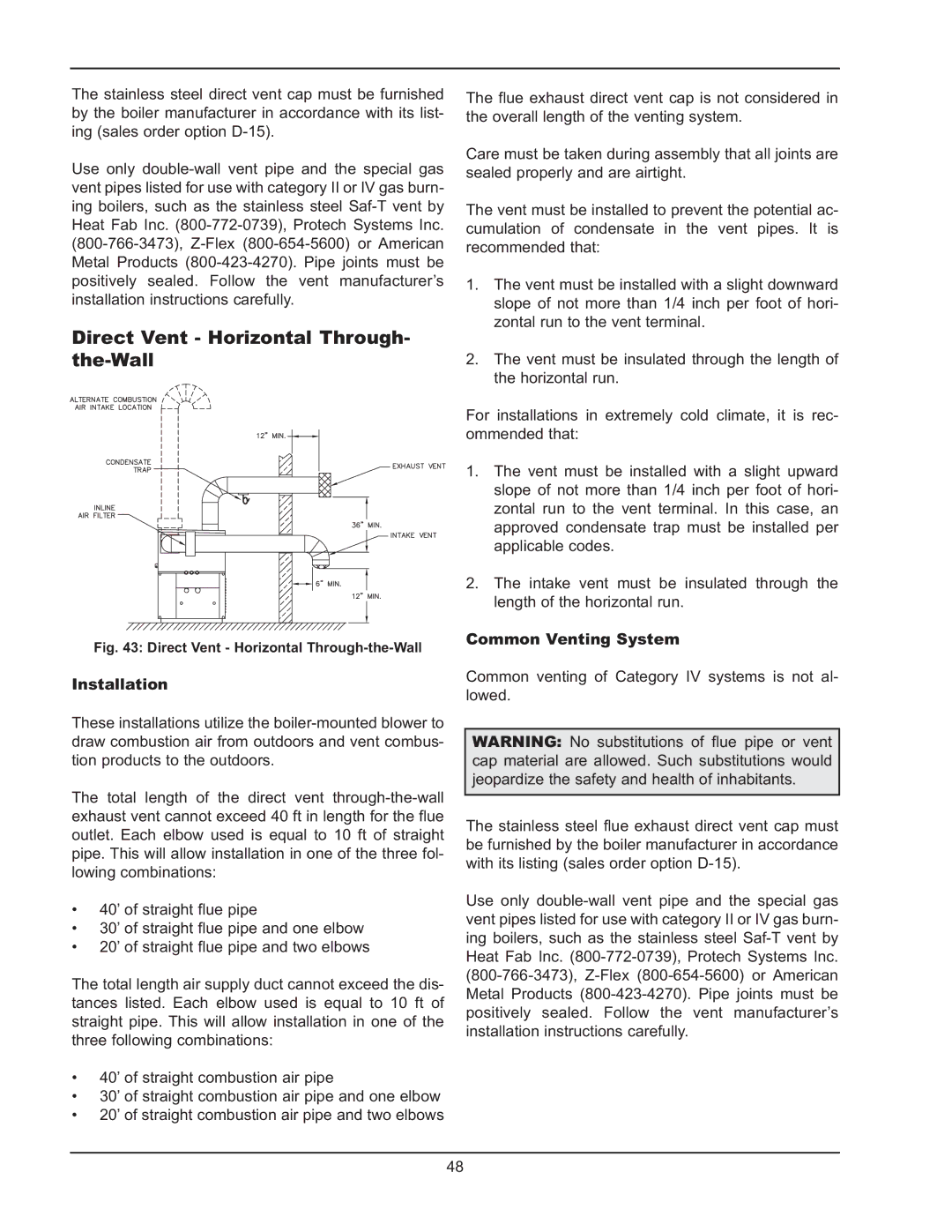

Direct Vent - Horizontal Through- the-Wall

Fig. 43: Direct Vent - Horizontal Through-the-Wall

Installation

These installations utilize the

The total length of the direct vent

•40’ of straight flue pipe

•30’ of straight flue pipe and one elbow

•20’ of straight flue pipe and two elbows

The total length air supply duct cannot exceed the dis- tances listed. Each elbow used is equal to 10 ft of straight pipe. This will allow installation in one of the three following combinations:

•40’ of straight combustion air pipe

•30’ of straight combustion air pipe and one elbow

•20’ of straight combustion air pipe and two elbows

The flue exhaust direct vent cap is not considered in the overall length of the venting system.

Care must be taken during assembly that all joints are sealed properly and are airtight.

The vent must be installed to prevent the potential ac- cumulation of condensate in the vent pipes. It is recommended that:

1.The vent must be installed with a slight downward slope of not more than 1/4 inch per foot of hori- zontal run to the vent terminal.

2.The vent must be insulated through the length of the horizontal run.

For installations in extremely cold climate, it is rec- ommended that:

1.The vent must be installed with a slight upward slope of not more than 1/4 inch per foot of hori- zontal run to the vent terminal. In this case, an approved condensate trap must be installed per applicable codes.

2.The intake vent must be insulated through the length of the horizontal run.

Common Venting System

Common venting of Category IV systems is not al- lowed.

WARNING: No substitutions of flue pipe or vent cap material are allowed. Such substitutions would jeopardize the safety and health of inhabitants.

The stainless steel flue exhaust direct vent cap must be furnished by the boiler manufacturer in accordance with its listing (sales order option

Use only

48