Motor Specifications and Electrical Requirements (continued)

Motor Safety Protection

IMPORTANT: To reduce the risk of motor damage, the motor should be blown out or vacuumed frequently to keep sawdust from interfering with normal motor ventila- tion.

1.Connect this tool to a power source with the appropriate voltage for your model and a

a

2.If the motor won't start, turn off the power switch immediately and unplug the tool. Check the spindle to make sure it turns freely. If the spindle is free, try to start the motor again. If the motor still does not start, refer to the "Trouble- shooting” chart.

3.If the motor suddenly stalls while sand- ing, turn off the power switch, unplug the tool, and remove the workpiece from the belt/drum. The motor may now be restarted and the sanding finished.

4.Fuses may "blow" or circuit breakers may trip frequently if:

a.Motor Is

b.Line voltages should not be more

than 10% above or below the name- plate voltage. For heavy loads, how- ever, the voltage at motor terminals must equal the voltage specified for your model.

5.Most motor troubles may be traced to loose or incorrect connections, over- load, low voltage (such as small size wire in the supply circuit) or to overly long supply circuit wire. Always check the connections, the load and supply circuit whenever motor doesn't work well. Check wire sizes and extension cord length with the Wire Size Chart.

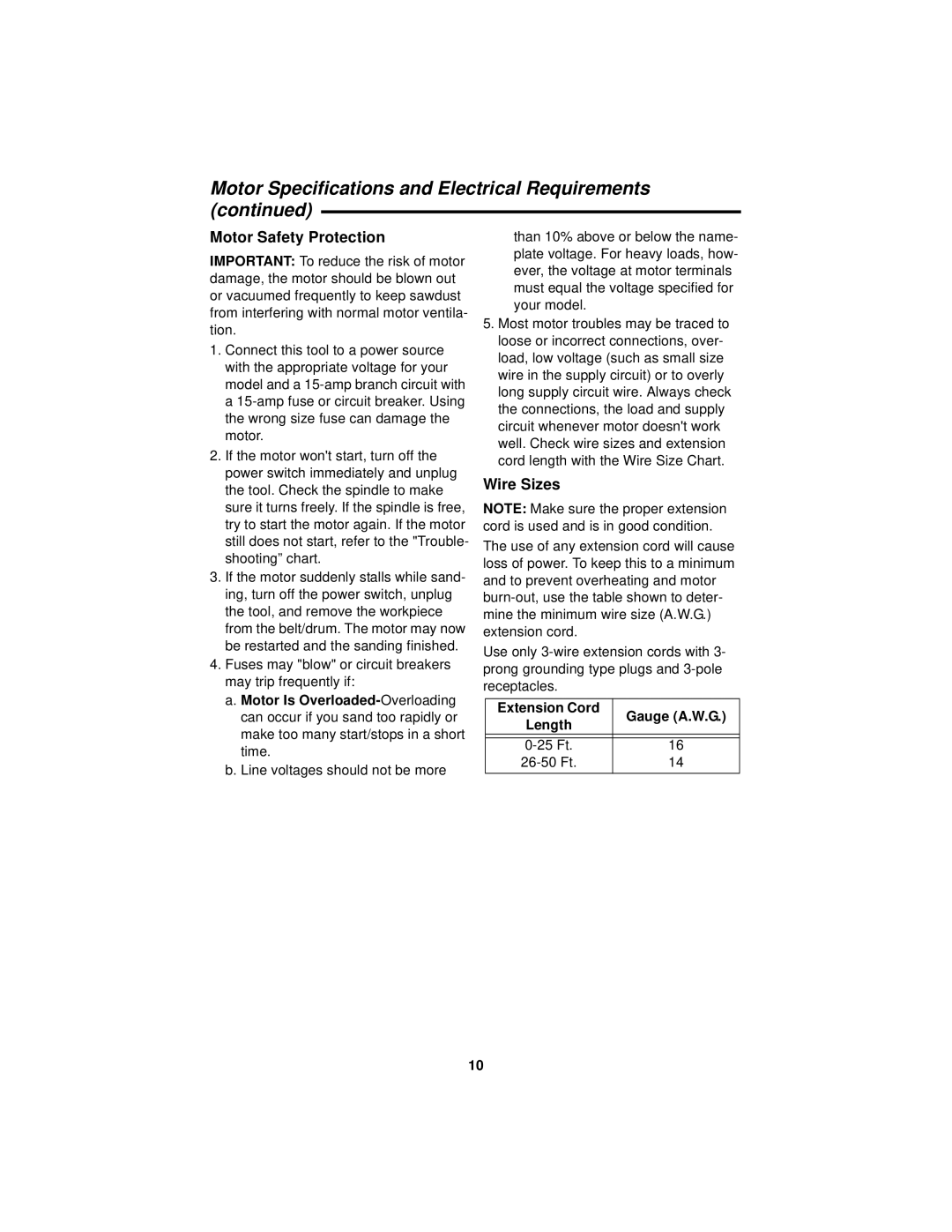

Wire Sizes

NOTE: Make sure the proper extension cord is used and is in good condition. The use of any extension cord will cause loss of power. To keep this to a minimum and to prevent overheating and motor

Use only

Extension Cord | Gauge (A.W.G.) | |

Length | ||

| ||

|

| |

16 | ||

14 | ||

|

|

10