Assembly (continued)

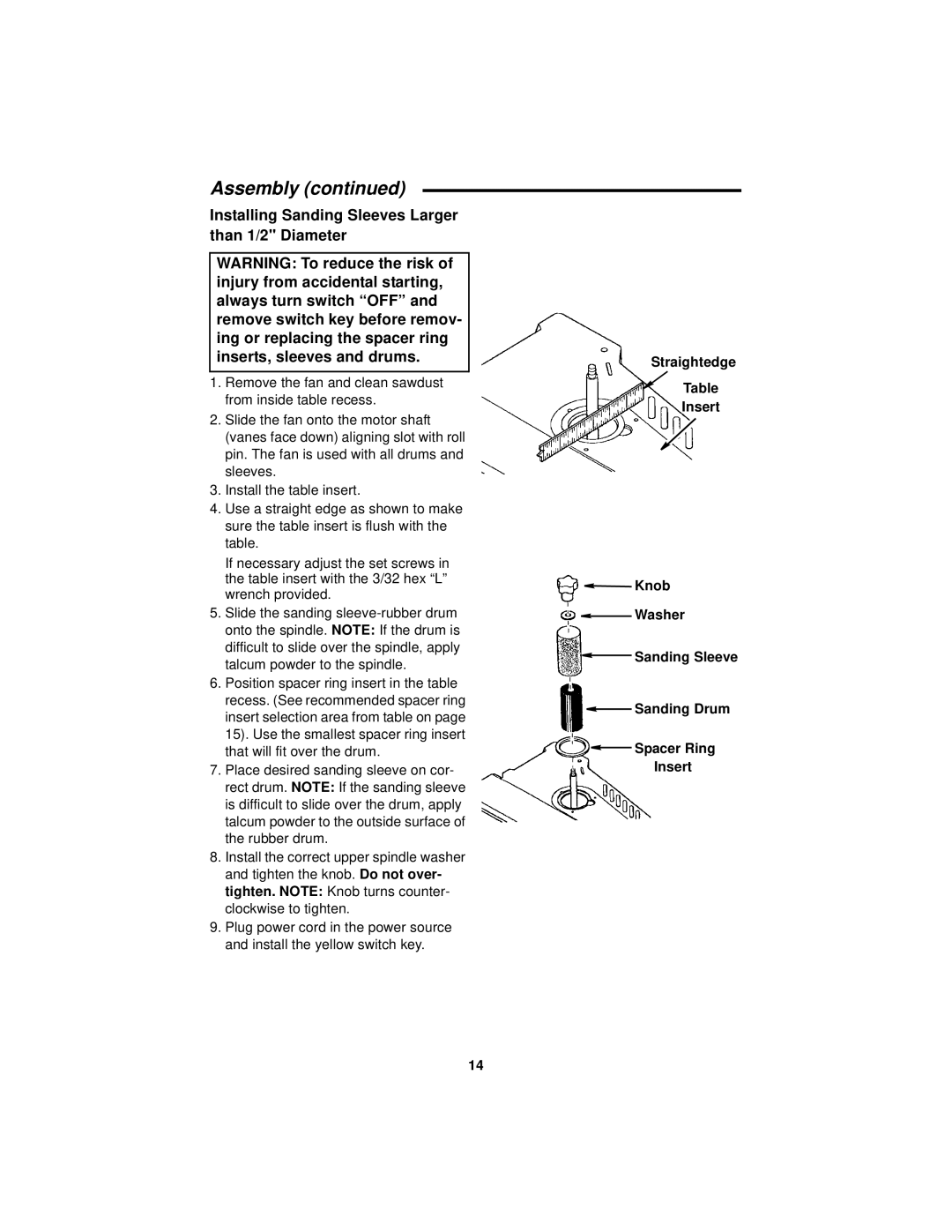

Installing Sanding Sleeves Larger than 1/2" Diameter

WARNING: To reduce the risk of injury from accidental starting, always turn switch “OFF” and remove switch key before remov- ing or replacing the spacer ring inserts, sleeves and drums.

1.Remove the fan and clean sawdust from inside table recess.

2.Slide the fan onto the motor shaft (vanes face down) aligning slot with roll pin. The fan is used with all drums and sleeves.

3.Install the table insert.

4.Use a straight edge as shown to make sure the table insert is flush with the table.

If necessary adjust the set screws in the table insert with the 3/32 hex “L” wrench provided.

5.Slide the sanding

6.Position spacer ring insert in the table recess. (See recommended spacer ring insert selection area from table on page 15). Use the smallest spacer ring insert that will fit over the drum.

7.Place desired sanding sleeve on cor- rect drum. NOTE: If the sanding sleeve is difficult to slide over the drum, apply talcum powder to the outside surface of the rubber drum.

8.Install the correct upper spindle washer and tighten the knob. Do not over- tighten. NOTE: Knob turns counter- clockwise to tighten.

9.Plug power cord in the power source and install the yellow switch key.

Straightedge

Table

Insert

![]() Knob

Knob

![]() Washer

Washer

![]() Sanding Sleeve

Sanding Sleeve

![]() Sanding Drum

Sanding Drum

![]() Spacer Ring Insert

Spacer Ring Insert

14