Assembly (continued)

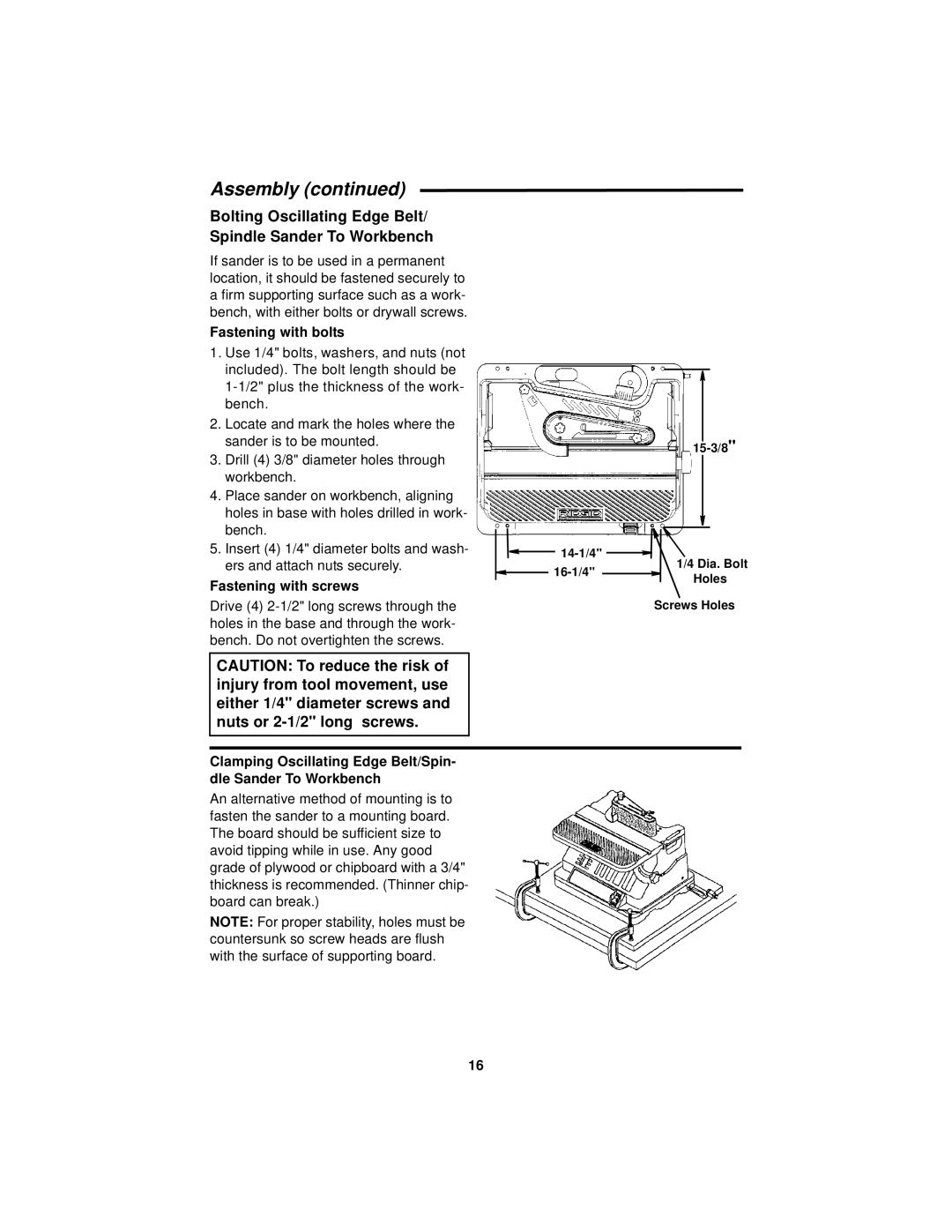

Bolting Oscillating Edge Belt/ Spindle Sander To Workbench

If sander is to be used in a permanent location, it should be fastened securely to a firm supporting surface such as a work- bench, with either bolts or drywall screws.

Fastening with bolts

1.Use 1/4" bolts, washers, and nuts (not included). The bolt length should be

2.Locate and mark the holes where the sander is to be mounted.

3.Drill (4) 3/8" diameter holes through workbench.

4.Place sander on workbench, aligning holes in base with holes drilled in work- bench.

5.Insert (4) 1/4" diameter bolts and wash- ers and attach nuts securely.

Fastening with screws

Drive (4)

![]()

![]()

1/4 Dia. Bolt

Holes

Screws Holes

CAUTION: To reduce the risk of injury from tool movement, use either 1/4" diameter screws and nuts or

Clamping Oscillating Edge Belt/Spin- dle Sander To Workbench

An alternative method of mounting is to fasten the sander to a mounting board. The board should be sufficient size to avoid tipping while in use. Any good grade of plywood or chipboard with a 3/4" thickness is recommended. (Thinner chip- board can break.)

NOTE: For proper stability, holes must be countersunk so screw heads are flush with the surface of supporting board.

16