Installing Sanding Sleeves for the 1/2" Diameter Sanding Drum

WARNING: To reduce the risk of injury from accidental starting, always turn switch “OFF”, unplug the sander and remove switch key before removing or replacing the spacer ring inserts, sleeves and drums.

1.Remove the fan and clean sawdust from inside table recess.

2.Slide the fan onto the motor shaft (vanes face down) aligning slot with roll pin. The fan is used with all sanding operations.

3.Install the table insert.

4.Use a straight edge as shown to make sure the table insert is flush with the table

If necessary adjust the set screws in the table insert with the 3/32 hex “L” wrench provided.

5.Position 15/16" inside diameter spacer

ring insert in the table recess.

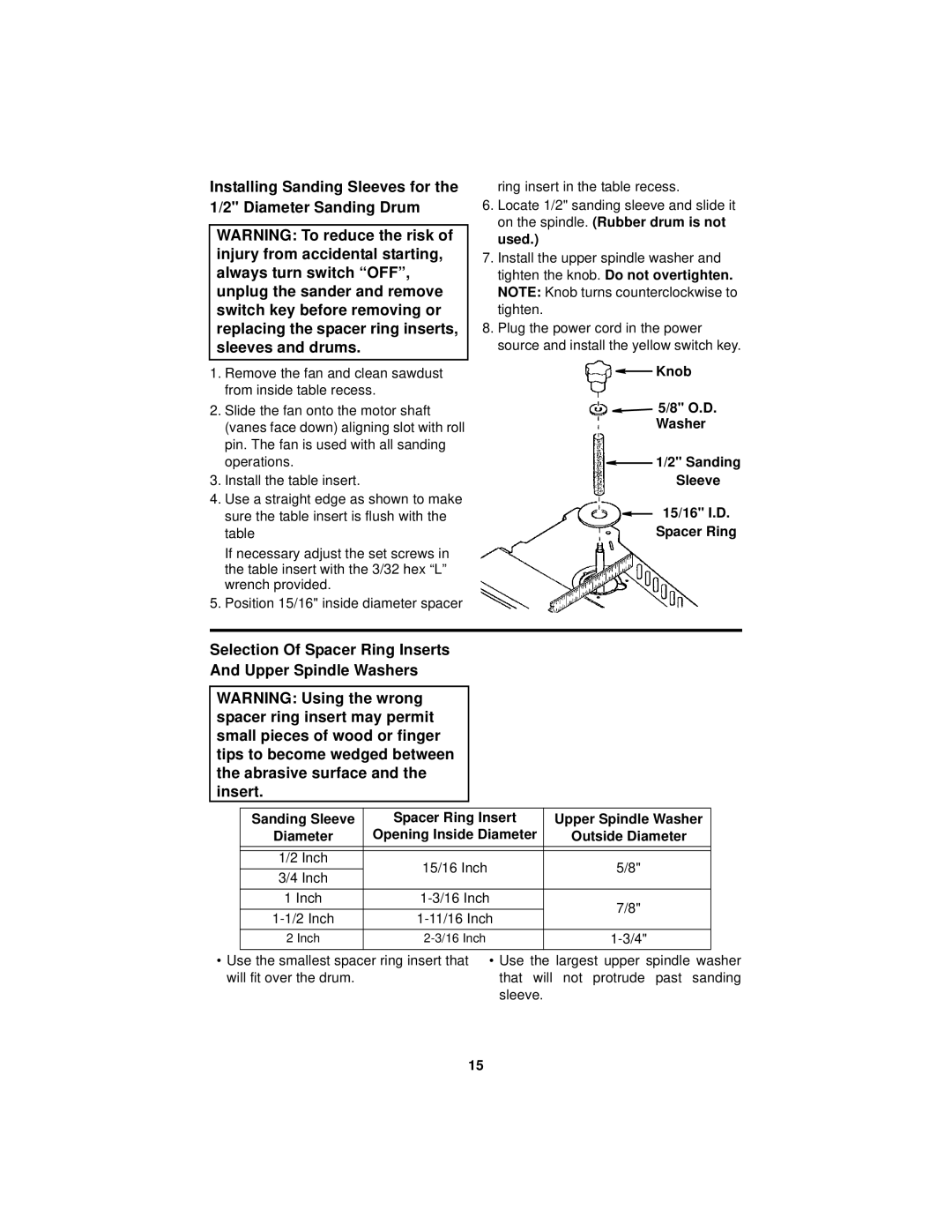

6.Locate 1/2" sanding sleeve and slide it on the spindle. (Rubber drum is not used.)

7.Install the upper spindle washer and tighten the knob. Do not overtighten. NOTE: Knob turns counterclockwise to tighten.

8.Plug the power cord in the power source and install the yellow switch key.

Knob

Knob

5/8" O.D.

Washer

1/2" Sanding

1/2" Sanding

Sleeve

15/16" I.D.

Spacer Ring

Selection Of Spacer Ring Inserts

And Upper Spindle Washers

WARNING: Using the wrong spacer ring insert may permit small pieces of wood or finger tips to become wedged between the abrasive surface and the insert.

Sanding Sleeve | Spacer Ring Insert | Upper Spindle Washer | |

Diameter | Opening Inside Diameter | Outside Diameter | |

|

|

| |

|

|

| |

1/2 Inch | 15/16 Inch | 5/8" | |

| |||

3/4 Inch | |||

|

| ||

|

|

| |

1 Inch | 7/8" | ||

|

| ||

| |||

|

|

| |

2 Inch | |||

|

|

|

•Use the smallest spacer ring insert that will fit over the drum.

•Use the largest upper spindle washer that will not protrude past sanding sleeve.

15