Work Feed Devices (continued)

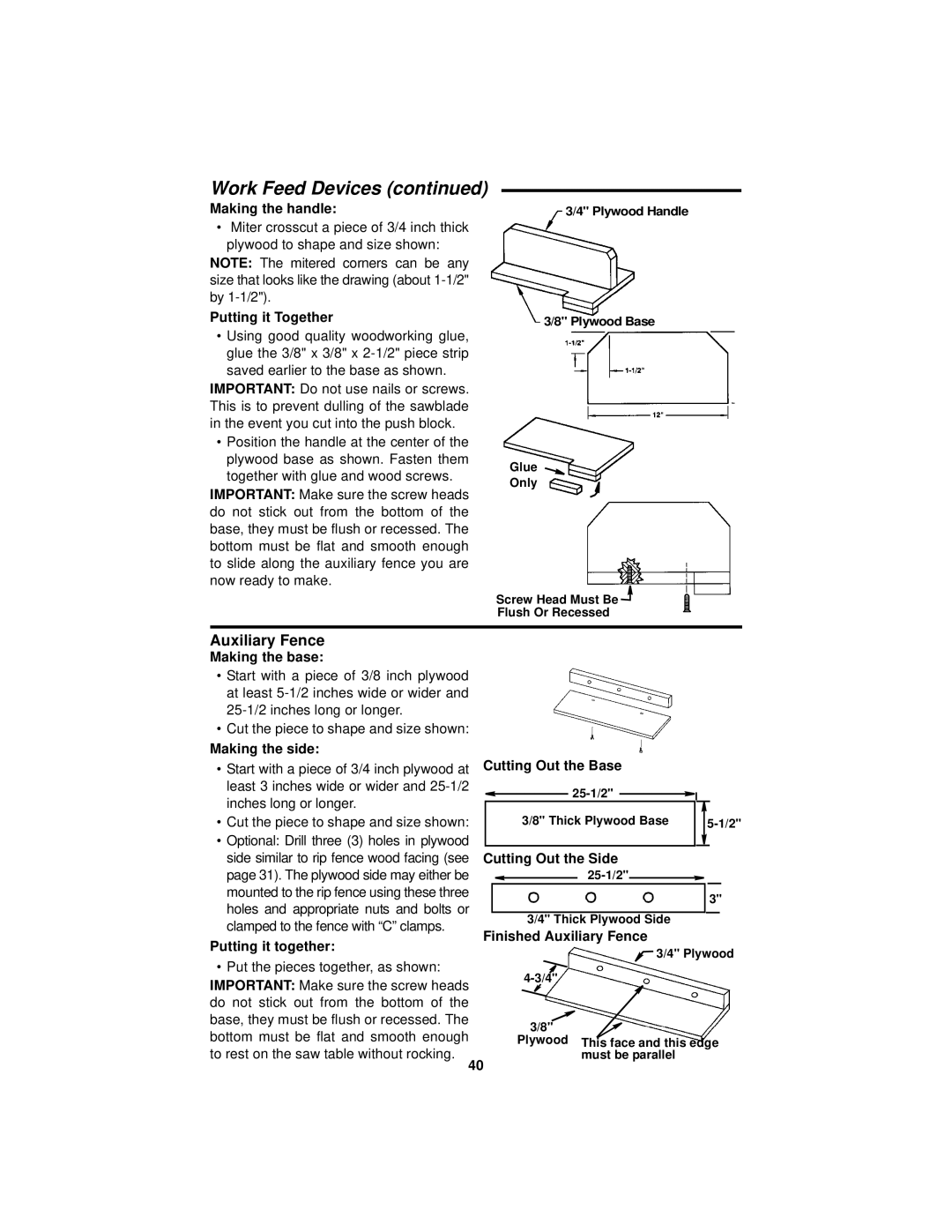

Making the handle:

•Miter crosscut a piece of 3/4 inch thick plywood to shape and size shown:

NOTE: The mitered corners can be any size that looks like the drawing (about

Putting it Together

•Using good quality woodworking glue, glue the 3/8" x 3/8" x

IMPORTANT: Do not use nails or screws. This is to prevent dulling of the sawblade in the event you cut into the push block.

•Position the handle at the center of the plywood base as shown. Fasten them together with glue and wood screws.

IMPORTANT: Make sure the screw heads do not stick out from the bottom of the base, they must be flush or recessed. The bottom must be flat and smooth enough to slide along the auxiliary fence you are now ready to make.

3/4" Plywood Handle

3/8" Plywood Base

Glue

Only

Screw Head Must Be ![]()

Flush Or Recessed

Auxiliary Fence

Making the base:

•Start with a piece of 3/8 inch plywood at least

•Cut the piece to shape and size shown:

Making the side:

•Start with a piece of 3/4 inch plywood at least 3 inches wide or wider and

•Cut the piece to shape and size shown:

•Optional: Drill three (3) holes in plywood side similar to rip fence wood facing (see page 31). The plywood side may either be mounted to the rip fence using these three holes and appropriate nuts and bolts or clamped to the fence with “C” clamps.

Putting it together:

•Put the pieces together, as shown: IMPORTANT: Make sure the screw heads do not stick out from the bottom of the base, they must be flush or recessed. The bottom must be flat and smooth enough to rest on the saw table without rocking.

Cutting Out the Base

| |

3/8" Thick Plywood Base |

Cutting Out the Side

![]()

![]()

![]() 3" 3/4" Thick Plywood Side

3" 3/4" Thick Plywood Side

Finished Auxiliary Fence

![]() 3/4" Plywood

3/4" Plywood

3/8"

Plywood This face and this edge must be parallel

40