Basic Saw Operations (continued)

Rabbeting

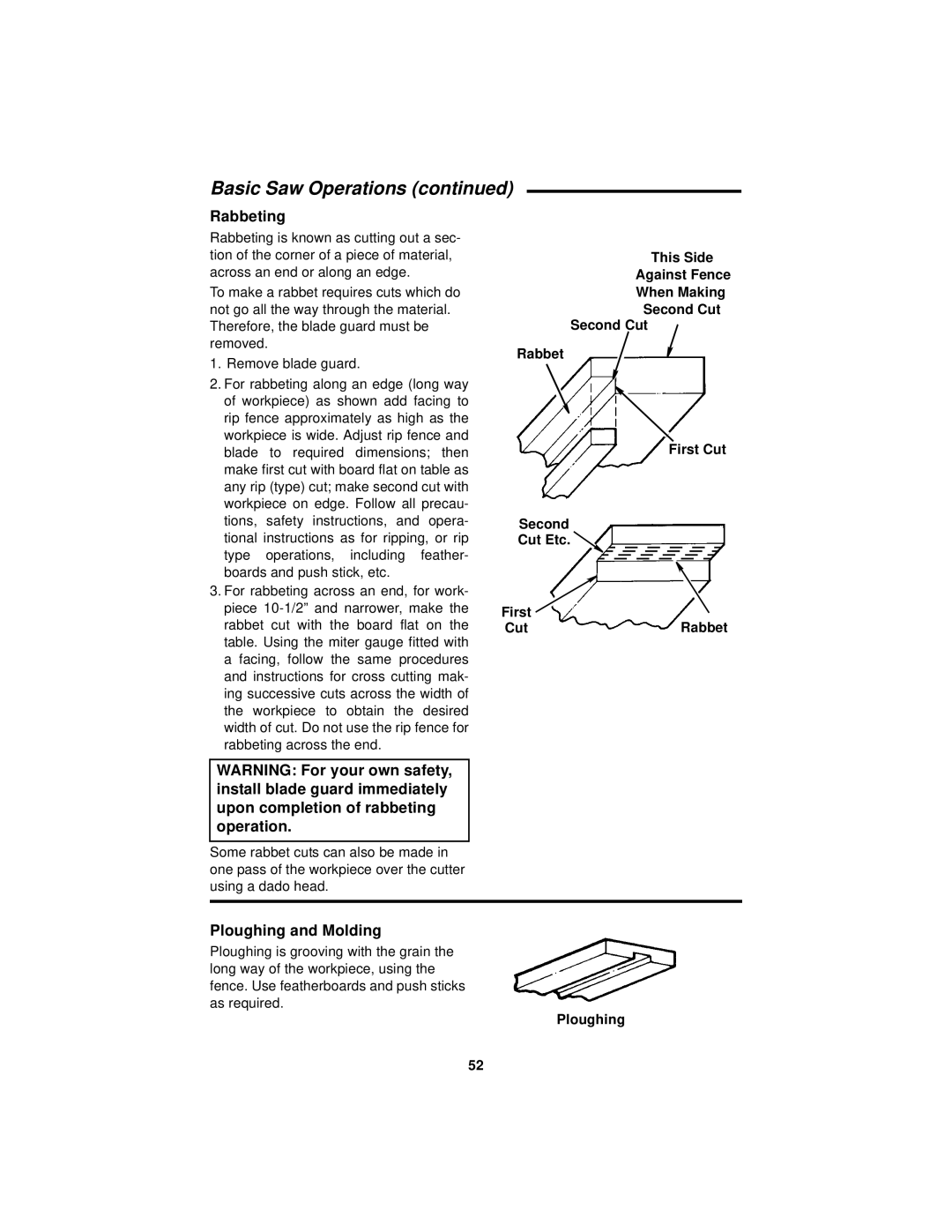

Rabbeting is known as cutting out a sec- tion of the corner of a piece of material, across an end or along an edge.

To make a rabbet requires cuts which do not go all the way through the material. Therefore, the blade guard must be removed.

1.Remove blade guard.

2.For rabbeting along an edge (long way of workpiece) as shown add facing to rip fence approximately as high as the workpiece is wide. Adjust rip fence and blade to required dimensions; then make first cut with board flat on table as any rip (type) cut; make second cut with workpiece on edge. Follow all precau- tions, safety instructions, and opera- tional instructions as for ripping, or rip type operations, including feather- boards and push stick, etc.

3.For rabbeting across an end, for work- piece

This Side

Against Fence

When Making

Second Cut

Second Cut

Rabbet

First Cut

Second

Cut Etc. ![]()

First | Rabbet |

Cut |

WARNING: For your own safety, install blade guard immediately upon completion of rabbeting operation.

Some rabbet cuts can also be made in one pass of the workpiece over the cutter using a dado head.

Ploughing and Molding

Ploughing is grooving with the grain the long way of the workpiece, using the fence. Use featherboards and push sticks as required.

Ploughing

52