WARNING: To reduce the risk of injury from unexpected starting or electrical shock, unplug the power cord before working on the saw.

WARNING: To reduce the risk of electrical shock, fire or injury, use only parts identical to those identified in the parts list reas- semble exactly as original assembly to reduce the risk of electrical hazards.

Replacing Carbon Brushes

The carbon brushes furnished will last approximately 50 hours of running time or 10,000 on/off cycles. Replace both carbon brushes when either brush has less than 1/4" length of carbon remaining. To inspect or replace first unplug the saw. Lower blade all the way, bevel to 45° and lock. Turn saw upside down. Then remove the motor cap on the end of the motor by removing 2 screws. NOTE: To reinstall the same brushes, first make sure the brushes go back in the way they came out. This will avoid a break in period that reduces performance and increases wear.

Remove the lead wires from the tabs on the brushes, then pull out the brushes. To

reassemble reverse the procedure. Tighten the screws snugly but do not overtighten.

Lubrication

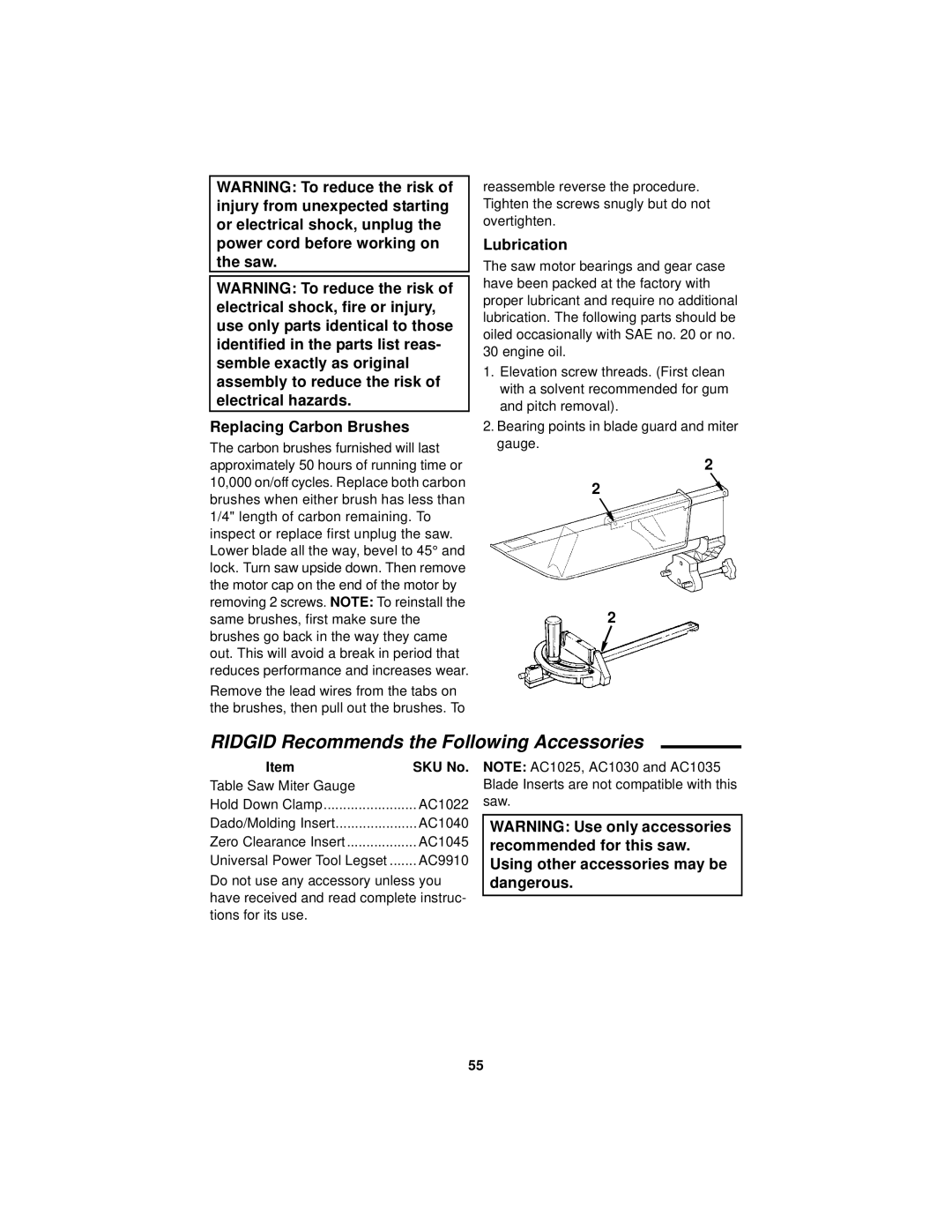

The saw motor bearings and gear case have been packed at the factory with proper lubricant and require no additional lubrication. The following parts should be oiled occasionally with SAE no. 20 or no. 30 engine oil.

1.Elevation screw threads. (First clean with a solvent recommended for gum and pitch removal).

2.Bearing points in blade guard and miter gauge.

2

2

2

RIDGID Recommends the Following Accessories

Item | SKU No. |

Table Saw Miter Gauge |

|

Hold Down Clamp | AC1022 |

Dado/Molding Insert | AC1040 |

Zero Clearance Insert | AC1045 |

Universal Power Tool Legset | AC9910 |

Do not use any accessory unless you have received and read complete instruc- tions for its use.

NOTE: AC1025, AC1030 and AC1035 Blade Inserts are not compatible with this saw.

WARNING: Use only accessories recommended for this saw. Using other accessories may be dangerous.

55