Page

About the User’s Guides

Contents

Printing

Using Your Printer in Linux

Troubleshooting

Important Precautions and Safety Information

Page

Laser Safety Statement

Recycling

Ozone Safety

Power Saver

FCC Information to the User

Radio Frequency Emissions

Canadian Radio Interference Regulations

EC Certification

Declaration of Conformity European Countries

Approvals and Certifications

Replacing the Fitted Plug for UK Only

Page

Differences Between British and American English

Getting Started

Starter Toner Cartridge

Quick Install Guide

Unpacking

Selecting a Location

Clearance Space

Rear View

Understanding the Component Location

Front View

These are the main components of your machine

Control Panel Functions

Installing the Toner Cartridge

Getting Started

Loading Paper

Changing the Paper Size in the Paper Tray

Getting Started

Making Connections

Using a Parallel Cable Windows only

Using a USB Cable

See your computer User’s Guide if you need help

To the USB port on your computer

Turning the Machine On

Windows GDI Driver

Remote Control Panel

About Samsung Software

Linux Driver

Fit to page printing Scale printing Watermark Overlay

Printer Driver Features

Feature Printer Driver

Installing Samsung Software in Windows

System Requirements

Installing Samsung Software

Getting Started

Getting Started

Installing Samsung SmarThru

Click Install SmarThru

Copy components to produce professional quality copies

Repairing Software

When the installation is finished, click Finish

Uninstalling the MFP Driver

Removing Software

Uninstalling Samsung SmarThru

Setting Up the Machine System

Changing the Display Language

Setting the Paper Size and Type

Power Save Mode

Using the Save Modes

Toner Save Mode

Memo

Paper Handling

Paper Type Input Source/Capacity Paper Tray

Selecting Print Materials

Type, Input Sources and Capacities

Plain paper

Guidelines for Paper and Special Materials

Selecting an Output Location

Printing to the Front Output Tray Face down

Transparencies

Printing to the Rear Output Slot Face up

Be careful not to pinch your fingers

Paper Handling

Loading Paper in the Paper Tray

Using the Manual Feeder

Paper Handling

Setting the Paper Type and Size for Manual Feeder

Memo

Printing

Printing a Document in Windows

LandscapePortrait

Select the Samsung SCX-4100 Series printer

From the Document menu

Canceling a Print Job

Double-click the Samsung SCX-4100 Series icon

Using a Favorite Setting

Using Help

Size

Setting Paper Properties

Property Description Copies

Loaded in the tray

Type

Setting Graphic Properties

Property Description Source

Select Color Paper

Quality

To print a document

Toner Save

Advanced

Printing Multiple Pages on One Sheet of the Paper

Download as Bit Image When this

When the Print All Text Black option is

Property Description Advanced True Type Options

Right, Then Down, Then Left, Then

Printing a Reduced or Enlarged Document

You can scale your print job on a

Fitting Your Document to a Selected Paper Size

Printing Posters

Click Ok and start printing

Using Watermarks

Using an Existing Watermark

Creating a Watermark

Editing a Watermark

Deleting a Watermark

Creating a New Page Overlay

Using Overlays

What is an Overlay?

Click the Extras tab and click Edit in the Overlay section

Edit Overlays window, click Create Overlay

Using a Page Overlay

Deleting a Page Overlay

Click Delete Overlay

Windows 9x/Me

Setting Up the Locally Shared Printer

Setting Up the Host Computer

Setting Up the Client Computer

Windows NT 4.0/2000/XP

Select Local Port and click New Port

Copying

Loading Paper for Copying

Preparing a Document

Making a Copy

Copying

Number of Copies

Setting Copy Options

Darkness

Press No. of Copies

Reduced/Enlarged Copying

Original Type

Using Special Copy Features

Clone Copying

Auto Fit Copying

Sided in 1 page Copying

Up Copying

Poster Copying

Changing the Default Settings

Setting the Time Out Option

Scanning

Scanning Using Samsung SmarThru

Scanning Basics

SmarThru 4 window opens

Scan To

Print

Image

Copy

Application

Web

Setting

To use on-line help file

Scanning Process with TWAIN- enabled Software

Using Your Printer Linux

Getting Started

Recommended Hardware Requirements

Installing the MFP Driver

Supported OS

Software

Installing the MFP Driver

Click Install When the welcome screen appears, click Next

When the installation is completed, click Finish

Click Uninstall

Click Next Click Finish

Double-click MFP Configurator on the desktop

Using the MFP Configurator

Opening the MFP Configurator

Printers Configuration

Printers Tab

Classes tab shows the list of the available printer classes

Scanners Configuration

Classes Tab

MFP Ports Configuration

Sharing Ports Between Printers and Scanners

Configuring Printer Properties

Change the printer and print job properties

Printing a Document

Printing from Applications

Device using the standard Cups way directly from

Printing Files

Scanning a Document

Click Properties

Drag the pointer to set the image area to be scanned

Using Your Printer in Linux

Using Preset Job Type Settings

Tools Function

Using the Image Editor

You can use the following tools to edit the image

Number of degrees from the drop-down list

Size manually, or set the rate to scale

Proportionally, vertically or horizontally

Allows you to flip the image vertically or

Memo

Maintenance

Press Start/Enter

Printing the System Data List

Clearing the Memory

System data list prints out

Cleaning the Inside

Cleaning Your Machine

Cleaning the Outside

Maintenance

Cleaning the Document Glass

Saving Toner

Maintaining the Toner Cartridge

Toner Cartridge Storage

Expected Cartridge Life

Open the front cover

Reinstall the cartridge and close the front cover

Redistributing Toner

Replacing the Toner Cartridge

Items

Consumables and Replacement Parts

Cleaning the Drum

Using the Remote Control Panel

Select Samsung SCX-4100 Series and then Remote Control Panel

Troubleshooting

Message Location of Jam Go to

Clearing Paper Jams

Paper Tray

Paper Exit Area

Troubleshooting

Fuser Area or Around the Toner Cartridge

Tips for Avoiding Paper Jams

Select 90 degrees Click

Clearing LCD Error Messages

Display Meaning Suggested solutions

Condition Suggested solutions

Solving Problems

Paper Feeding Problems

Select Samsung SCX-4100 Series as

Printing Problems

Condition Possible cause Suggested solutions

Selects print

Paper size settings do

Machine Paper source

Text is wrong

Select Download as Bit Image

Advanced Options window

Dropouts

Printing Quality Problems

Toner specks

If black vertical streaks appear on

Clean the LSU Clean the LSU. See

Clean the inside of the machine. See

See Replacing the Toner Cartridge on

Skew

Scatter

Characters

Curl or wave

See

On page A.5

Rotating the paper 180 in the tray

Black pages

Curl

Copying Problems

Scanning Problems

Common Linux Problems

Problem Possible Cause and Solution

Is not functioning properly

To identify the source of the problem, you should open

List

Dev/mfp4, so scanner on USB0 relates to /dev/mfp4

Please install the LPP first

Installed both Linux

Symbolic link to lpr printing command, which is

If you want to uninstall only one of them, please

Printer Specifications

General Specifications

Scanner and Copier Specifications

Paper Specifications

~ 163 g/m2, 16 ~ 43 lb

General Specifications

Package Weight Paper 2.5 Kg Plastic 0.7 Kg

Characters x 2 lines

Scanner and Copier Specifications

Min x 127 mm 3 x 5

Printer Specifications

Envelope C6, Envelope Monarch, Envelope B5

Max x 356 mm 8.5 x 14

Paper Specifications

Overview

Size mm/in Weight Capacity

Supported Sizes of Paper

Try another kind of paper

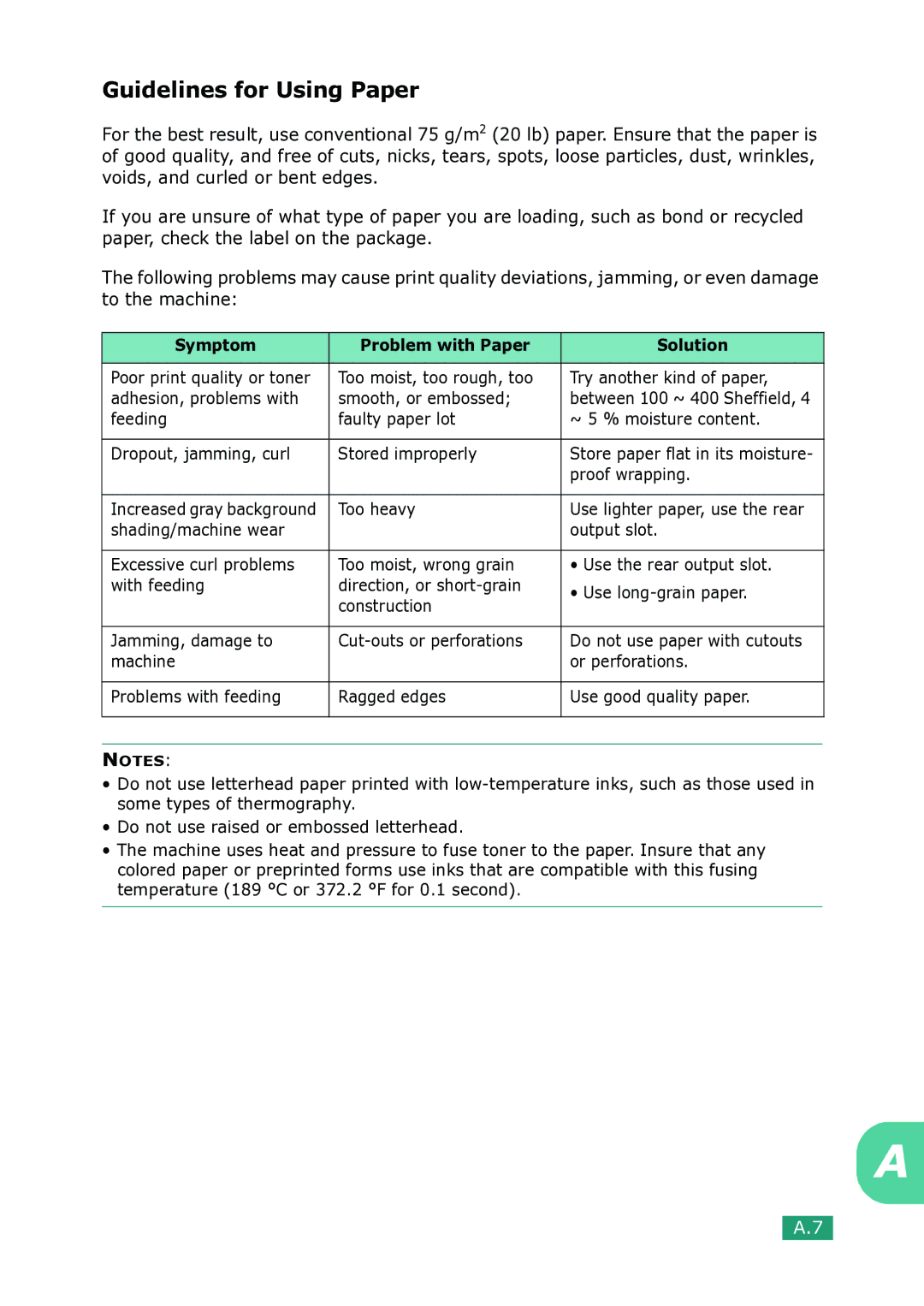

Guidelines for Using Paper

Adhesion, problems with Smooth, or embossed

Proof wrapping

Second

Paper Specifications

Paper Output Capacity

Paper Storage Environment

Envelopes

Envelopes with Double Side Seams

Envelope Storage

Envelopes with Adhesive Strips or Flaps

Envelope Margins

Type of Address Minimum Maximum

Labels

Transparencies

Index

Page

Mode, change Watermarks, use

Uninstalling MFP driver

Remote Control Panel 1.23 SmarThru

Visit us at