6. Air Purging

Air and moisture remaining in the refrigerant system have undesirable effects as indicated below. Therefore, they must be purged completely.

●pressure in the system rises

●operating current rises

●cooling (or heating) efficiency drops

●moisture in the air may freeze and block capillary tubing

●water may lead to corrosion of parts in the refrigerant sys- tem

■Air Purging with a Vacuum Pump (for Test Run)

(1) | Check that each tube (both narrow and wide tubes) |

| between the indoor and outdoor units have been properly |

| connected and all wiring for the test run has been com- |

| pleted. Note that both narrow and wide tube service |

| valves on the outdoor unit are kept closed at this stage. |

(2) | Using an adjustable wrench or box wrench, remove the |

| valve caps from the service valve on both narrow and |

| wide tubes. |

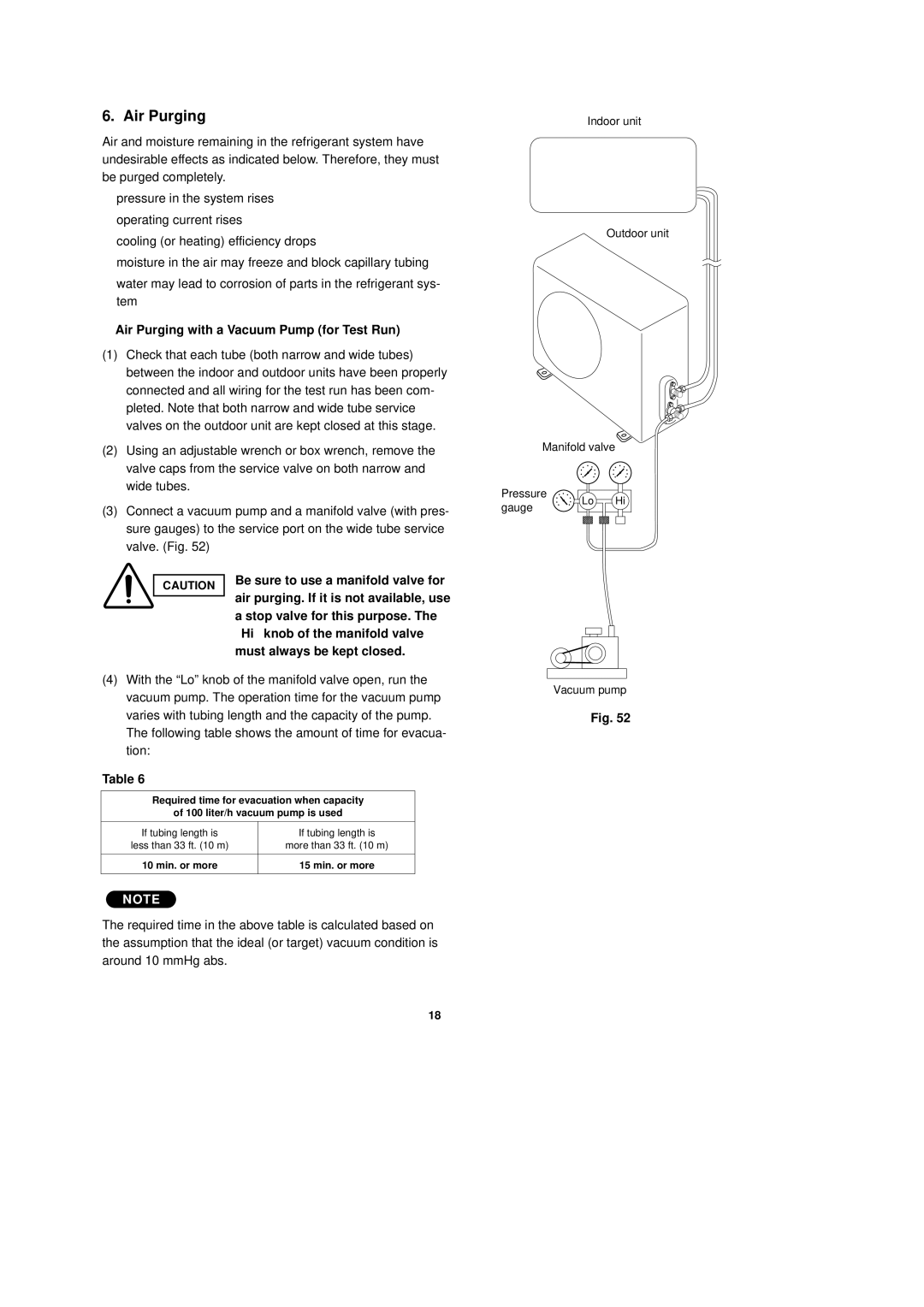

Indoor unit

Outdoor unit

Manifold valve

Pressure

(3) Connect a vacuum pump and a manifold valve (with pres- |

sure gauges) to the service port on the wide tube service |

valve. (Fig. 52) |

CAUTION | Be sure to use a manifold valve for | |

air purging. If it is not available, use | ||

| ||

| ||

| a stop valve for this purpose. The | |

| “Hi” knob of the manifold valve | |

| must always be kept closed. |

gauge

Lo Hi

(4)With the “Lo” knob of the manifold valve open, run the vacuum pump. The operation time for the vacuum pump varies with tubing length and the capacity of the pump. The following table shows the amount of time for evacua- tion:

Table 6

Required time for evacuation when capacity

of 100 liter/h vacuum pump is used

If tubing length is | If tubing length is |

less than 33 ft. (10 m) | more than 33 ft. (10 m) |

|

|

10 min. or more | 15 min. or more |

|

|

NOTE

The required time in the above table is calculated based on the assumption that the ideal (or target) vacuum condition is around 10 mmHg abs.

Vacuum pump

Fig. 52

18