5. Refrigerant Tubing

5-1. Use of the Flaring Method

Many of the conventional split system air conditioners employ the flaring method to connect refrigerant tubes which run between indoor and outdoor units. In this method, the copper tubes are flared at each end and connected with flare nuts.

5-2. Flaring Procedure with a Flare Tool

a)Cut the copper tube to the required length with a tube cutter. It is recommended to cut approx. 12 to 20 in. (30 to 50 cm) longer than the tubing length you estimate.

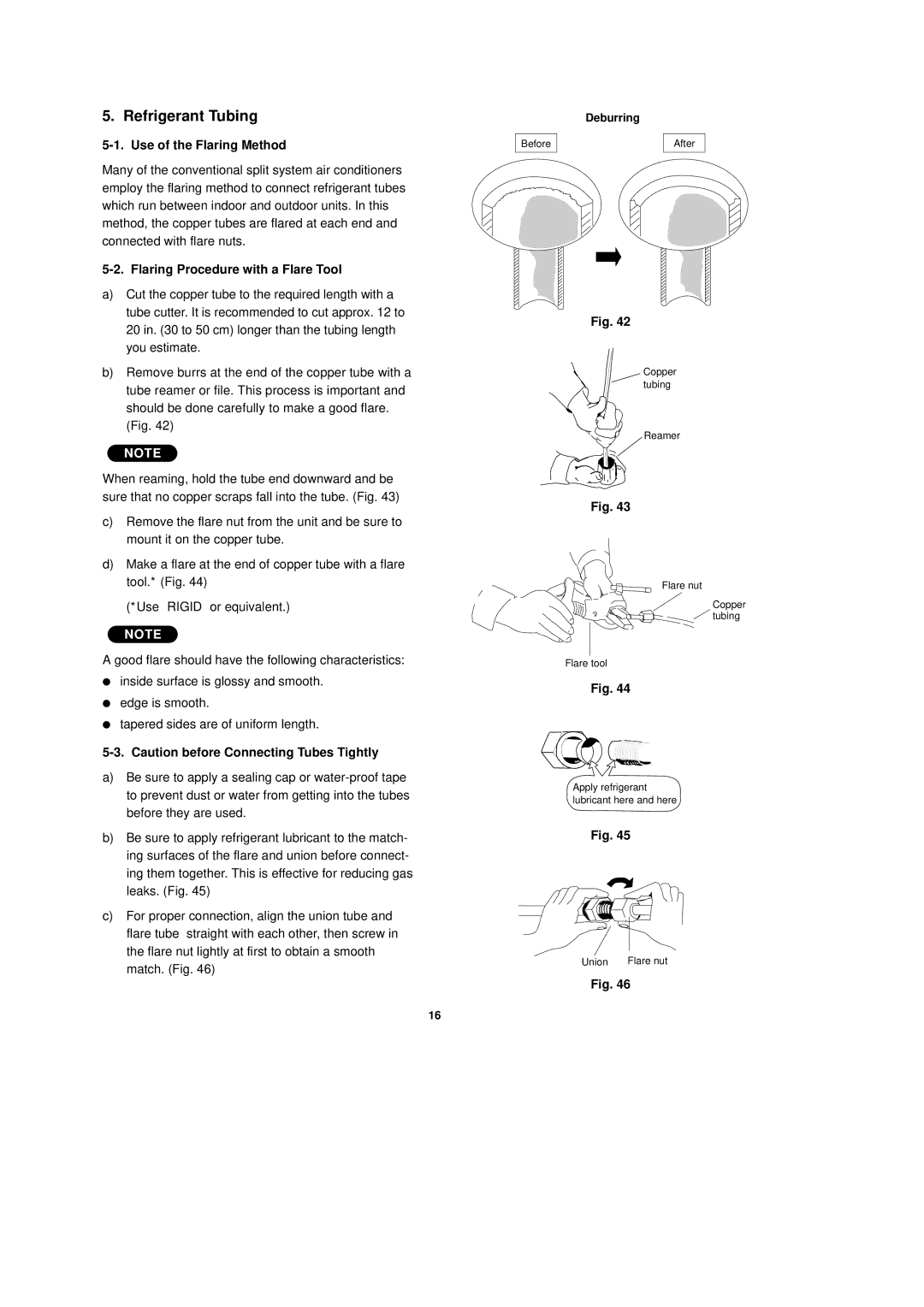

b)Remove burrs at the end of the copper tube with a tube reamer or file. This process is important and should be done carefully to make a good flare. (Fig. 42)

NOTE

When reaming, hold the tube end downward and be sure that no copper scraps fall into the tube. (Fig. 43)

c)Remove the flare nut from the unit and be sure to mount it on the copper tube.

d)Make a flare at the end of copper tube with a flare tool.* (Fig. 44)

(*Use “RIGID” or equivalent.)

NOTE

A good flare should have the following characteristics:

●inside surface is glossy and smooth.

●edge is smooth.

●tapered sides are of uniform length.

a)Be sure to apply a sealing cap or

b)Be sure to apply refrigerant lubricant to the match- ing surfaces of the flare and union before connect- ing them together. This is effective for reducing gas leaks. (Fig. 45)

c)For proper connection, align the union tube and flare tube straight with each other, then screw in the flare nut lightly at first to obtain a smooth match. (Fig. 46)

Deburring

Before | After |

Fig. 42

Copper tubing

Reamer

Fig. 43

Flare nut

Copper tubing

Flare tool

Fig. 44

Apply refrigerant lubricant here and here

Fig. 45

Union | Flare nut |

Fig. 46

16