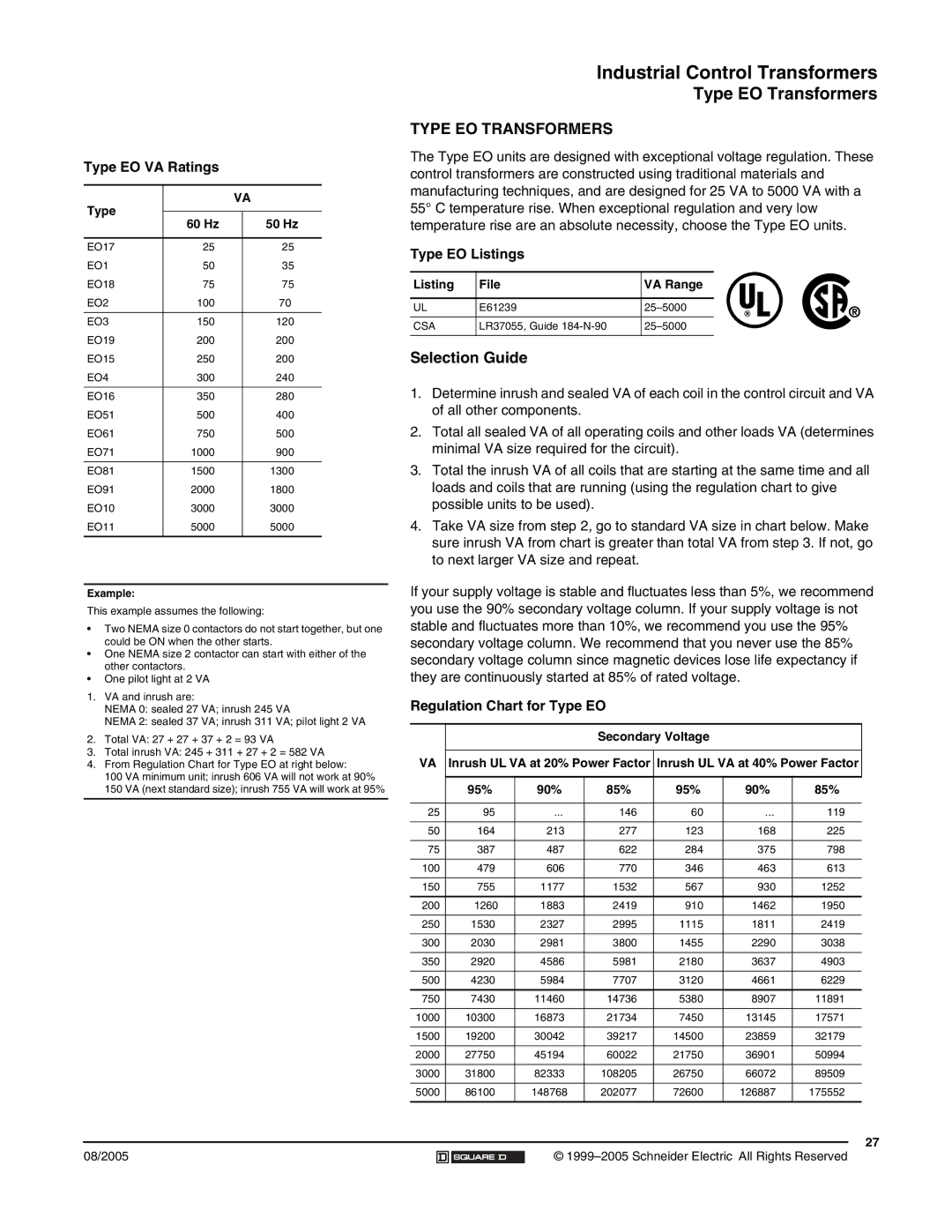

Type EO VA Ratings

Type |

| VA | |

|

|

| |

60 Hz |

| 50 Hz | |

|

| ||

|

|

|

|

EO17 | 25 |

| 25 |

EO1 | 50 |

| 35 |

EO18 | 75 |

| 75 |

EO2 | 100 |

| 70 |

|

|

|

|

EO3 | 150 |

| 120 |

EO19 | 200 |

| 200 |

EO15 | 250 |

| 200 |

EO4 | 300 |

| 240 |

|

|

|

|

EO16 | 350 |

| 280 |

EO51 | 500 |

| 400 |

EO61 | 750 |

| 500 |

EO71 | 1000 |

| 900 |

|

|

|

|

EO81 | 1500 |

| 1300 |

EO91 | 2000 |

| 1800 |

EO10 | 3000 |

| 3000 |

EO11 | 5000 |

| 5000 |

|

|

|

|

Industrial Control Transformers

Type EO Transformers

TYPE EO TRANSFORMERS

The Type EO units are designed with exceptional voltage regulation. These control transformers are constructed using traditional materials and manufacturing techniques, and are designed for 25 VA to 5000 VA with a 55° C temperature rise. When exceptional regulation and very low temperature rise are an absolute necessity, choose the Type EO units.

Type EO Listings

Listing | File | VA Range |

|

|

|

UL | E61239 | |

|

|

|

CSA | LR37055, Guide | |

|

|

|

Selection Guide

1.Determine inrush and sealed VA of each coil in the control circuit and VA of all other components.

2.Total all sealed VA of all operating coils and other loads VA (determines minimal VA size required for the circuit).

3.Total the inrush VA of all coils that are starting at the same time and all loads and coils that are running (using the regulation chart to give possible units to be used).

4.Take VA size from step 2, go to standard VA size in chart below. Make sure inrush VA from chart is greater than total VA from step 3. If not, go to next larger VA size and repeat.

Example:

This example assumes the following:

•Two NEMA size 0 contactors do not start together, but one could be ON when the other starts.

•One NEMA size 2 contactor can start with either of the other contactors.

•One pilot light at 2 VA

1.VA and inrush are:

NEMA 0: sealed 27 VA; inrush 245 VA

NEMA 2: sealed 37 VA; inrush 311 VA; pilot light 2 VA

2.Total VA: 27 + 27 + 37 + 2 = 93 VA

3.Total inrush VA: 245 + 311 + 27 + 2 = 582 VA

4.From Regulation Chart for Type EO at right below:

100 VA minimum unit; inrush 606 VA will not work at 90% 150 VA (next standard size); inrush 755 VA will work at 95%

If your supply voltage is stable and fluctuates less than 5%, we recommend you use the 90% secondary voltage column. If your supply voltage is not stable and fluctuates more than 10%, we recommend you use the 95% secondary voltage column. We recommend that you never use the 85% secondary voltage column since magnetic devices lose life expectancy if they are continuously started at 85% of rated voltage.

Regulation Chart for Type EO

|

|

| Secondary Voltage |

|

| |

|

|

|

| |||

VA | Inrush UL VA at 20% Power Factor | Inrush UL VA at 40% Power Factor | ||||

|

|

|

|

|

|

|

| 95% | 90% | 85% | 95% | 90% | 85% |

|

|

|

|

|

|

|

25 | 95 | ... | 146 | 60 | ... | 119 |

|

|

|

|

|

|

|

50 | 164 | 213 | 277 | 123 | 168 | 225 |

|

|

|

|

|

|

|

75 | 387 | 487 | 622 | 284 | 375 | 798 |

|

|

|

|

|

|

|

100 | 479 | 606 | 770 | 346 | 463 | 613 |

|

|

|

|

|

|

|

150 | 755 | 1177 | 1532 | 567 | 930 | 1252 |

|

|

|

|

|

|

|

200 | 1260 | 1883 | 2419 | 910 | 1462 | 1950 |

|

|

|

|

|

|

|

250 | 1530 | 2327 | 2995 | 1115 | 1811 | 2419 |

|

|

|

|

|

|

|

300 | 2030 | 2981 | 3800 | 1455 | 2290 | 3038 |

|

|

|

|

|

|

|

350 | 2920 | 4586 | 5981 | 2180 | 3637 | 4903 |

|

|

|

|

|

|

|

500 | 4230 | 5984 | 7707 | 3120 | 4661 | 6229 |

|

|

|

|

|

|

|

750 | 7430 | 11460 | 14736 | 5380 | 8907 | 11891 |

|

|

|

|

|

|

|

1000 | 10300 | 16873 | 21734 | 7450 | 13145 | 17571 |

|

|

|

|

|

|

|

1500 | 19200 | 30042 | 39217 | 14500 | 23859 | 32179 |

|

|

|

|

|

|

|

2000 | 27750 | 45194 | 60022 | 21750 | 36901 | 50994 |

|

|

|

|

|

|

|

3000 | 31800 | 82333 | 108205 | 26750 | 66072 | 89509 |

|

|

|

|

|

|

|

5000 | 86100 | 148768 | 202077 | 72600 | 126887 | 175552 |

|

|

|

|

|

|

|

27

08/2005 |

|

|

| © |