E N C A P S U L AT I N G

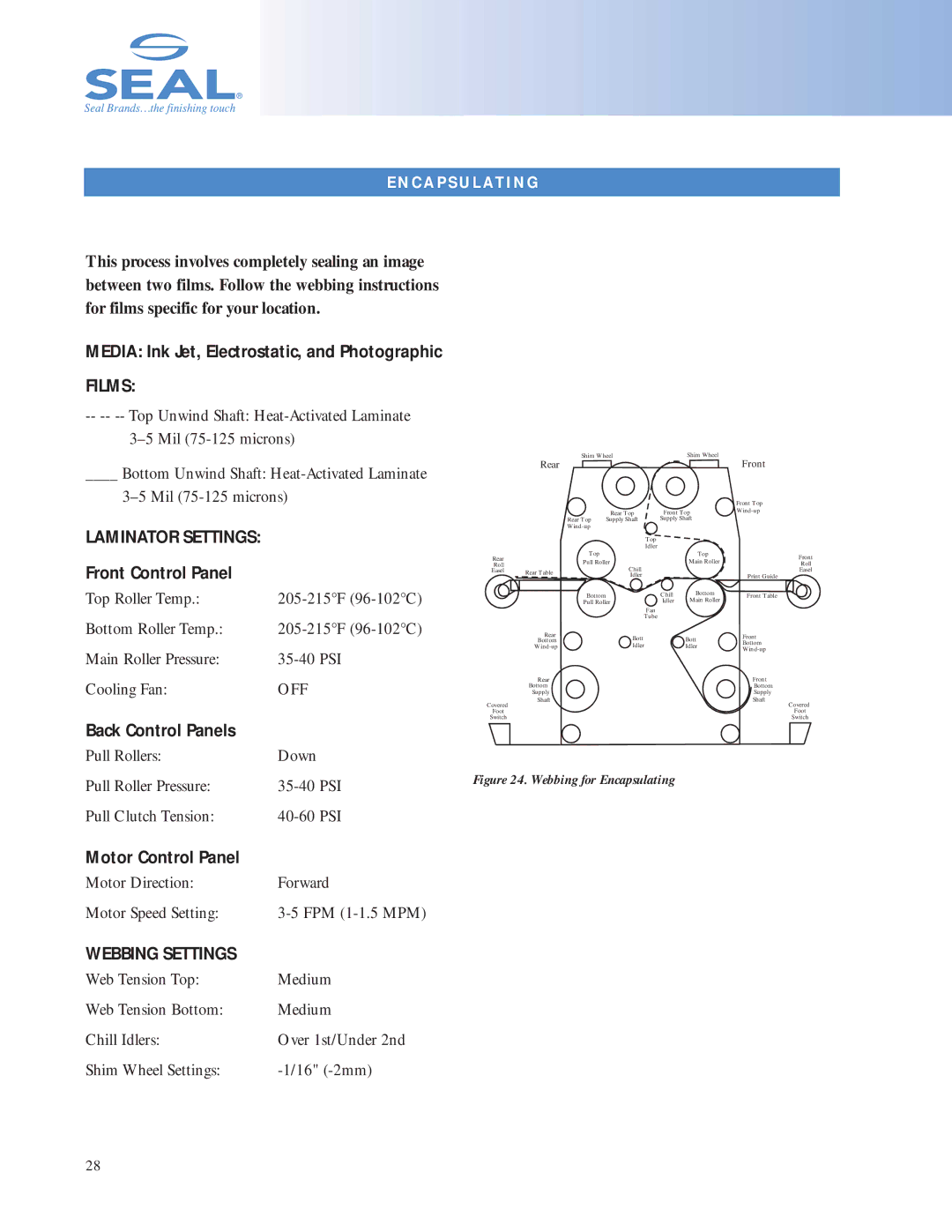

This process involves completely sealing an image between two films. Follow the webbing instructions for films specific for your location.

MEDIA: Ink Jet, Electrostatic, and Photographic

FILMS:

--

____ Bottom Unwind Shaft:

LAMINATOR SETTINGS: |

|

Front Control Panel |

|

Top Roller Temp.: | |

Bottom Roller Temp.: | |

Main Roller Pressure: | |

Cooling Fan: | OFF |

Back Control Panels |

|

Pull Rollers: | Down |

Pull Roller Pressure: | |

Pull Clutch Tension: | |

Motor Control Panel |

|

Motor Direction: | Forward |

Motor Speed Setting: | |

WEBBING SETTINGS |

|

Web Tension Top: | Medium |

Web Tension Bottom: | Medium |

Chill Idlers: | Over 1st/Under 2nd |

Shim Wheel Settings: |

28

| Rear | Shim Wheel |

| Shim Wheel | Front | |

|

|

|

|

| ||

|

|

|

|

|

| Front Top |

|

|

| Rear Top | Front Top | ||

|

| Rear Top | Supply Shaft | Supply Shaft |

| |

|

|

|

|

|

| |

|

|

| Top |

|

|

|

|

|

| Idler |

|

|

|

Rear |

| Top |

|

| Top | Front |

| Pull Roller |

| Main Roller | |||

Roll |

|

| Roll | |||

Easel | Rear Table |

| Chill |

|

| Easel |

|

| Idler |

|

| Print Guide | |

|

|

|

|

| ||

|

| Bottom | Chill | Bottom | Front Table | |

|

| Pull Roller | Idler | Main Roller |

| |

|

|

| Fan |

|

|

|

|

|

| Tube |

|

|

|

| Rear |

| Bott |

| Bott | Front |

| Bottom |

|

| |||

|

| Idler |

| Idler | Bottom | |

|

|

| ||||

|

|

|

|

|

| |

| Rear |

|

|

|

| Front |

| Bottom |

|

|

|

| Bottom |

| Supply |

|

|

|

| Supply |

Covered | Shaft |

|

|

|

| Shaft |

|

|

|

|

| Covered | |

Foot |

|

|

|

|

| Foot |

Switch |

|

|

|

|

| Switch |