assembJy

iNSTALLING AND TENSIONING BELT

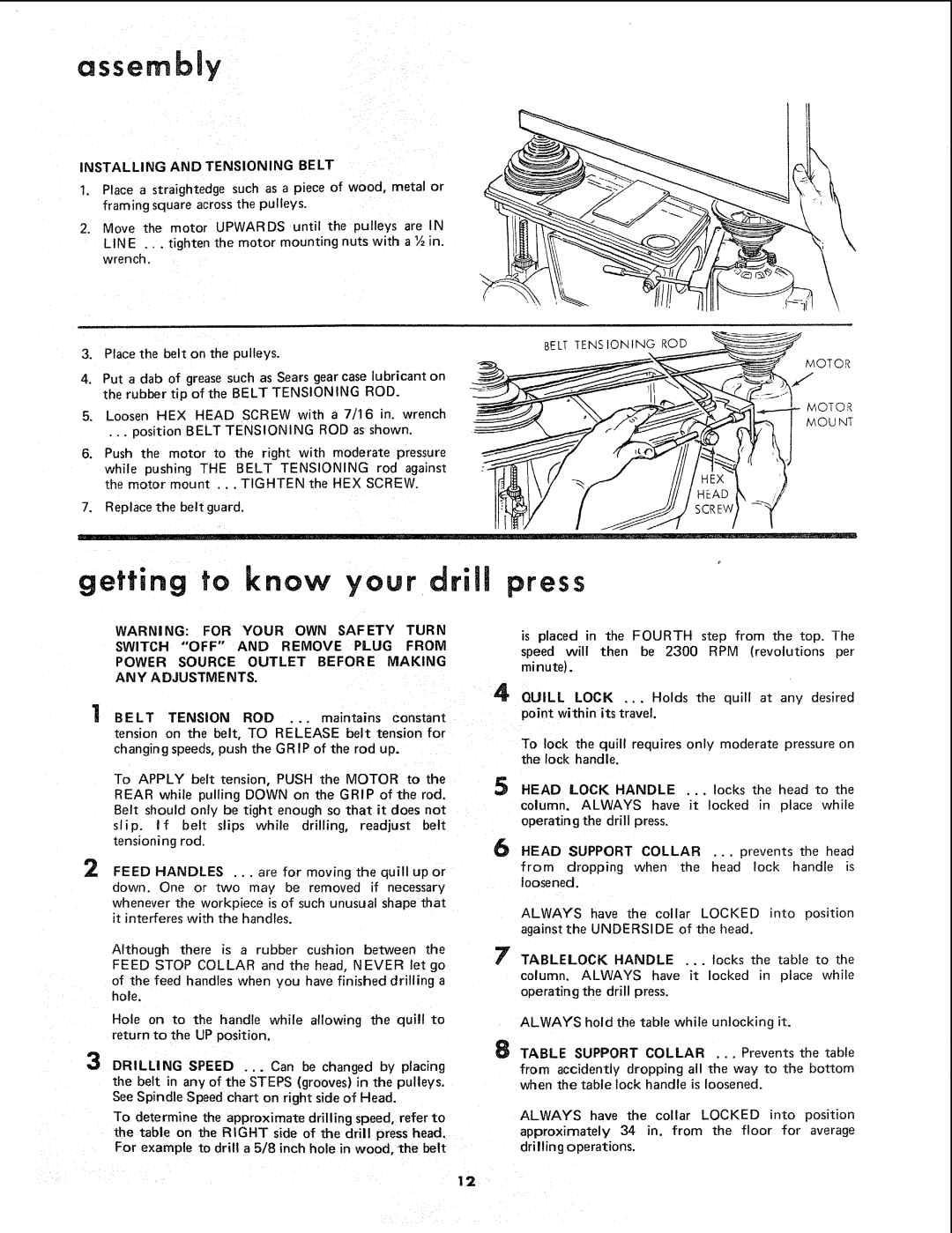

1.Place a straightedge such as a piece of wood, metal or framing square across the pulleys.

2.Move the motor UPWARDS until the pulleys are IN

LINE ... tighten the motor mounting nuts with a ½ in. wrench.

3.Place the belt on the pulleys.

4.Put a dab of grease such as Sears gear case lubricant on the rubber tip of the BELT TENSIONING ROD.

5.Loosen HEX HEAD SCREW with a 7/16 in. wrench

... position BELT TENSIONING ROD as shown.

6.Push the motor to the right with moderate pressure

while pushing THE BELT TENSIONING rod against

the motor mount ... TIGHTEN the HEX SCREW.

7.Replace the beltguard.

BELT TENSIONING ROD

/

MOTOR

MOTOR MOUNT

getting to know your driJJ press

WARNING: | FOR | YOUR | OWN | SAFETY | TURN |

SWITCH | "OFF" | AND REMOVE | PLUG | FROM | |

POWER | SOURCE | OUTLET | BEFORE | MAKING | |

ANY ADJUSTMENTS.

BELT TENSION ROD ... maintains constant tension on the belt, TO RELEASE belt tension for changing speeds, push the GRIP of the rod up.

To APPLY belt tension, PUSH the MOTOR to the REAR while pulling DOWN on the GRIP of the rod. Belt should only be tight enough so that it does not

slip. If belt slips while drilling, readjust belt tensioning rod

2 FEED HANDLES ... are for moving the quill up or down. One or two may be removed if necessary whenever the workpiece is of such unusual shape that it interferes with the handles.

Although there is a rubber cushion between the FEED STOP COLLAR and the head, NEVER let go of the feed handles when you have finished drilling a hole.

Hole on to the handle while allowing the quill to return to the UP position.

3 DRILLING SPEED ... Can be changed by placing

the belt in any of the STEPS (grooves) in the pulleys.

See Spindle Speed chart on right side of Head.

To determine the approximate drilling speed, refer to the table on the RIGHT side of the drill press head. For example to drill a 5/8 inch hole in wood, the belt

is placed in the FOURTH step from the top. The

speed will then be 2300 RPM (revolutions per minute).

4 QUILL LOCK ... Holds the quill at any desired

point within its travel.

To lock the quill requires only moderate pressure on the lock handle.

5 HEAD LOCK HANDLE ... locks the head to the

column. ALWAYS have it locked in place while operating the drill press.

6 HEAD SUPPORT COLLAR ... prevents the head

from dropping when the head lock handle is loosened.

ALWAYS have the collar LOCKED into position

against the UNDERSIDE of the head.

7 TABLELOCK HANDLE ... locks the table to the

column. ALWAYS have it locked in place while operating the drill press.

ALWAYS hold the table while unlocking it.

8 TABLE SUPPORT COLLAR ... Prevents the table

from accidently dropping all the way to the bottom when the table lock handle is loosened.

ALWAYS have the collar LOCKED into position

approximately 34 in. from the floor for average drilling operations.

12