_{_ The DEPTH POINTER is locked in place with the

THUMBSCREW.

!_ L FEED STOP NUT limits the downward movement of the quill at any desired point within its travel, and prevents the pointer from moving upward.

DR! LLING TO DEPTH

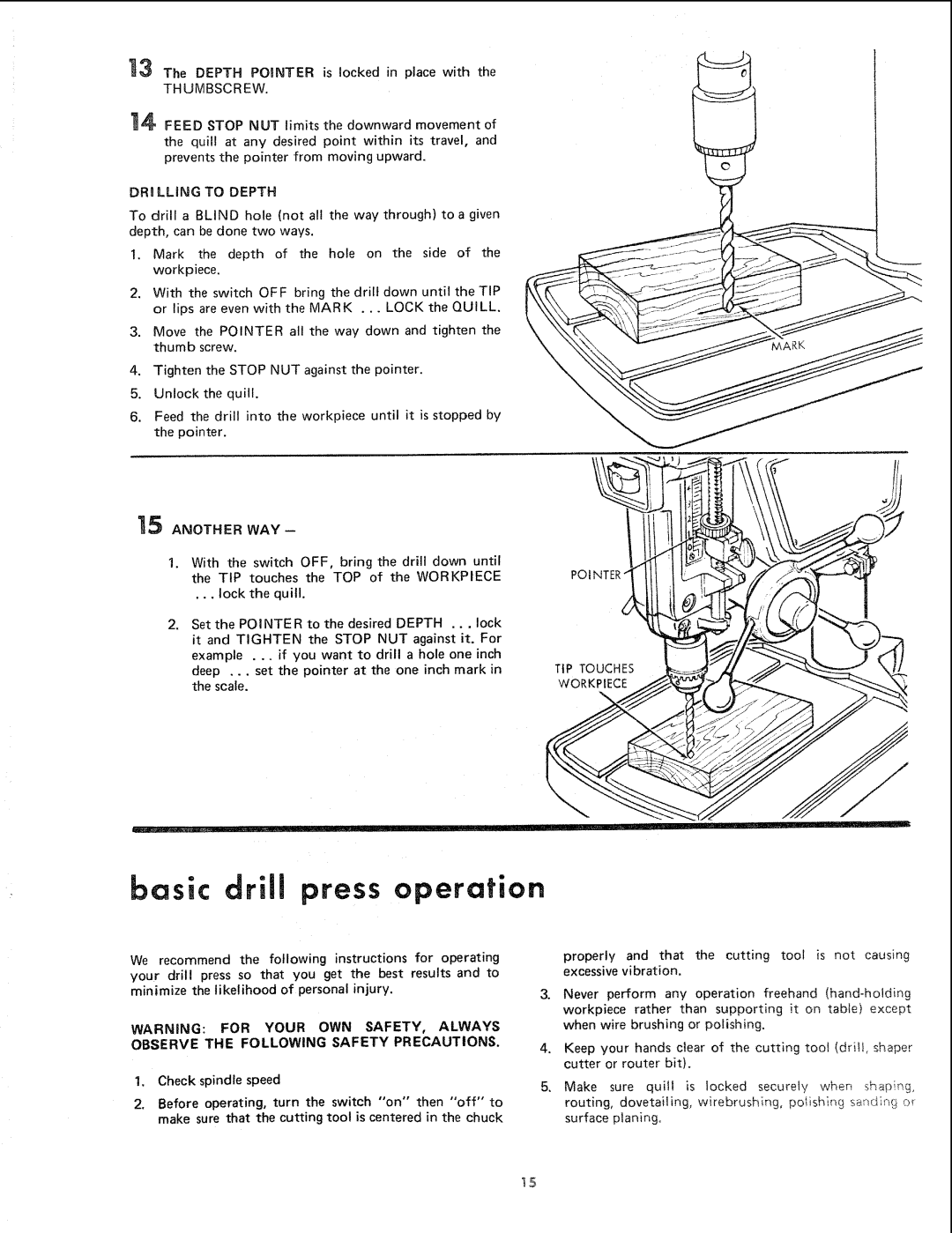

To drill a BLIND hole (not all the way through) to a given depth, can be done two ways.

1. Mark the depth of the hole on the side of the workpiece.

2.With the switch OFF bring the drill down until the TIP

or lips are even with the MARK ... LOCK the QUILL.

3.Move the POINTER all the way down and tighten the thumb screw.

4.Tighten the STOP NUT against the pointer.

5.Unlock the quill.

6.Feed the drill into the workpiece until it is stopped by the pointer.

J

_5 ANOTHER WAY--

1.With the switch OFF, bring the drill down until the TIP touches the TOP of the WORKPIECE

•..lock the quill.

2.Set the POINTE R to the desired DEPTH ... lock

it and TIGHTEN the STOP NUT against it. For example ... if you want to drill a hole one inch deep ... set the pointer at the one inch mark in the scale.

' I

basic drill press operation

TIP TOUCHES

WORKPIEC_

We recommend the following instructions for operating your drill press so that you get the best results and to minimize the likelihood of personal injury.

WARNING: FOR YOUR OWN SAFETY, ALWAYS OBSERVE THE FOLLOWING SAFETY PRECAUTIONS.

1.Check spindle speed

2.Before operating, turn the switch "on" then "off" to make sure that the cutting tool is centered in the chuck

properly and that the cutting tool is not causing excessive vibration.

3. Never perform any operation freehand

workpiece rather than supporting it on table) except when wire brushing or polishing.

4.Keep your hands clear of the cutting tool (drill, shaper cutter or router bit).

5.Make sure quill is locked securely when _haping,

routing, dovetailing, wirebrushing, polishing s_ndh',,_ or surface planing,

_5