OPERATION

CROSS CUTTING/RIP CUTTING

See Figure 19.

When making a cross cut or rip cut, align the line of cut with the outer blade guide notch on the base as shown in the figure.

Since blade thicknesses vary, always make a trial cut in scrap material along a guideline to determine how much, if any, you must offset the guideline to produce an accurate cut.

NOTE: The distance from the line of cut to the guideline is the amount you should offset the guide.

TOP VIEW OF SAW

BLADE GUIDELINE

GUIDE NOTCH

1

0 45

1 2 3

4

ALIGN OUTER BLADE GUIDE NOTCH ON SAW BASE WITH LINE OF CUT AS SHOWN WHEN MAKING CROSS CUTS OR RIP CUTS

Fig. 19

TO RIP CUT WITHOUT EDGE GUIDE

See Figure 20.

Use a guide when making long or wide rip cuts with the saw.

Follow these directions to rip cut:

nSecure the workpiece.

nClamp a straight edge to the workpiece using

nSaw along the straight edge to achieve a straight rip cut.

NOTE: Do not bind the blade in the cut.

WORKPIECE

3 450

30 ![]() 2 2

2 2

4

3 ![]() 2

2

1 54![]()

![]() 0

0

1

| NOTE: |

| BOTH ENDS OF STRAIGHT |

STRAIGHT | EDGE BEFORE MAKING CUT |

EDGE | Fig. 20 |

|

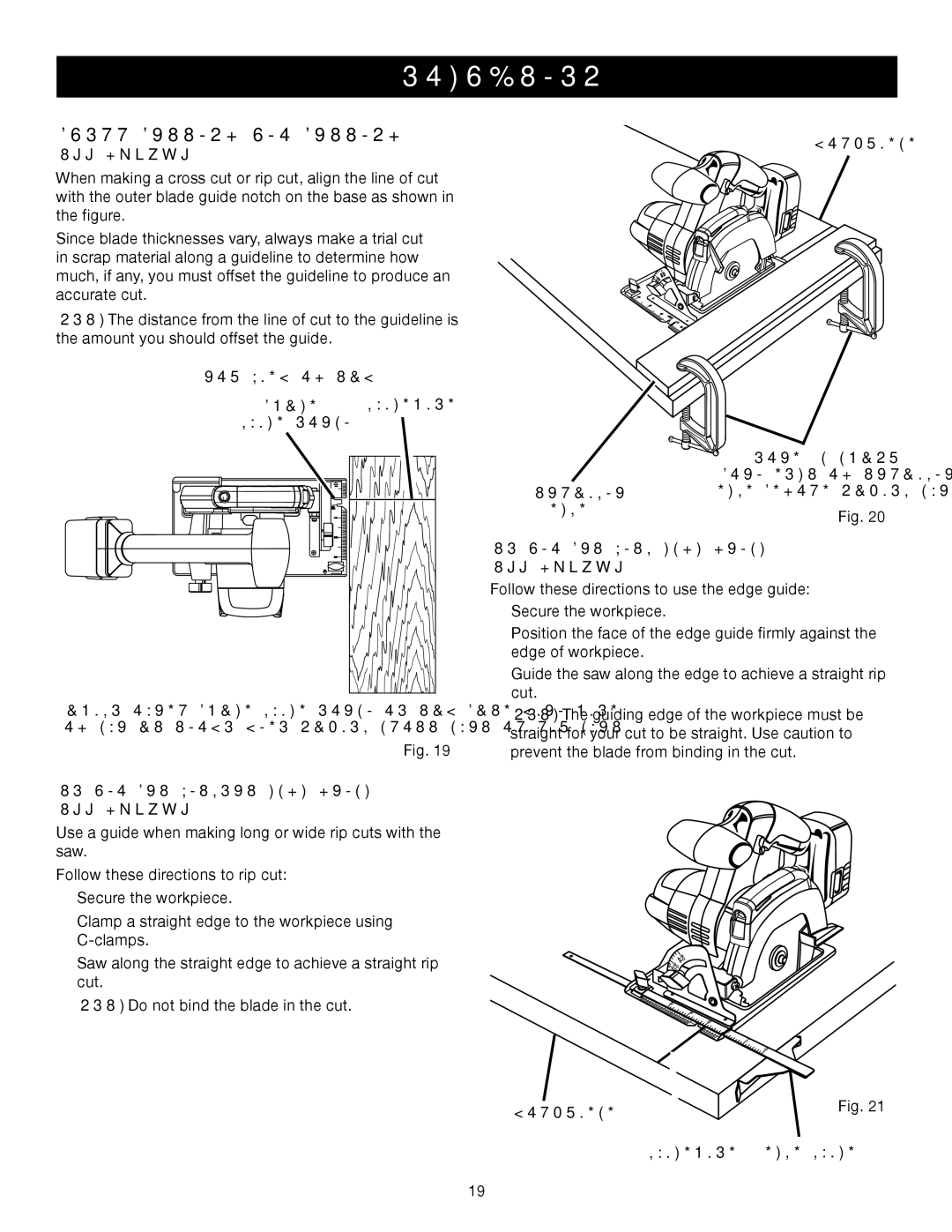

TO RIP CUT WITH EDGE GUIDE

See Figure 21.

Follow these directions to use the edge guide:

nSecure the workpiece.

nPosition the face of the edge guide firmly against the edge of workpiece.

nGuide the saw along the edge to achieve a straight rip cut.

NOTE: The guiding edge of the workpiece must be straight for your cut to be straight. Use caution to prevent the blade from binding in the cut.

5

4 0

5

3 |

0 |

22 |

5![]()

![]()

![]() 4 3 2

4 3 2 ![]() 1

1 ![]() 0

0

WORKPIECE | Fig. 21 |

|

GUIDELINE | EDGE GUIDE |

19