MAINTENANCE AND REPAIR INSTRUCTIONS

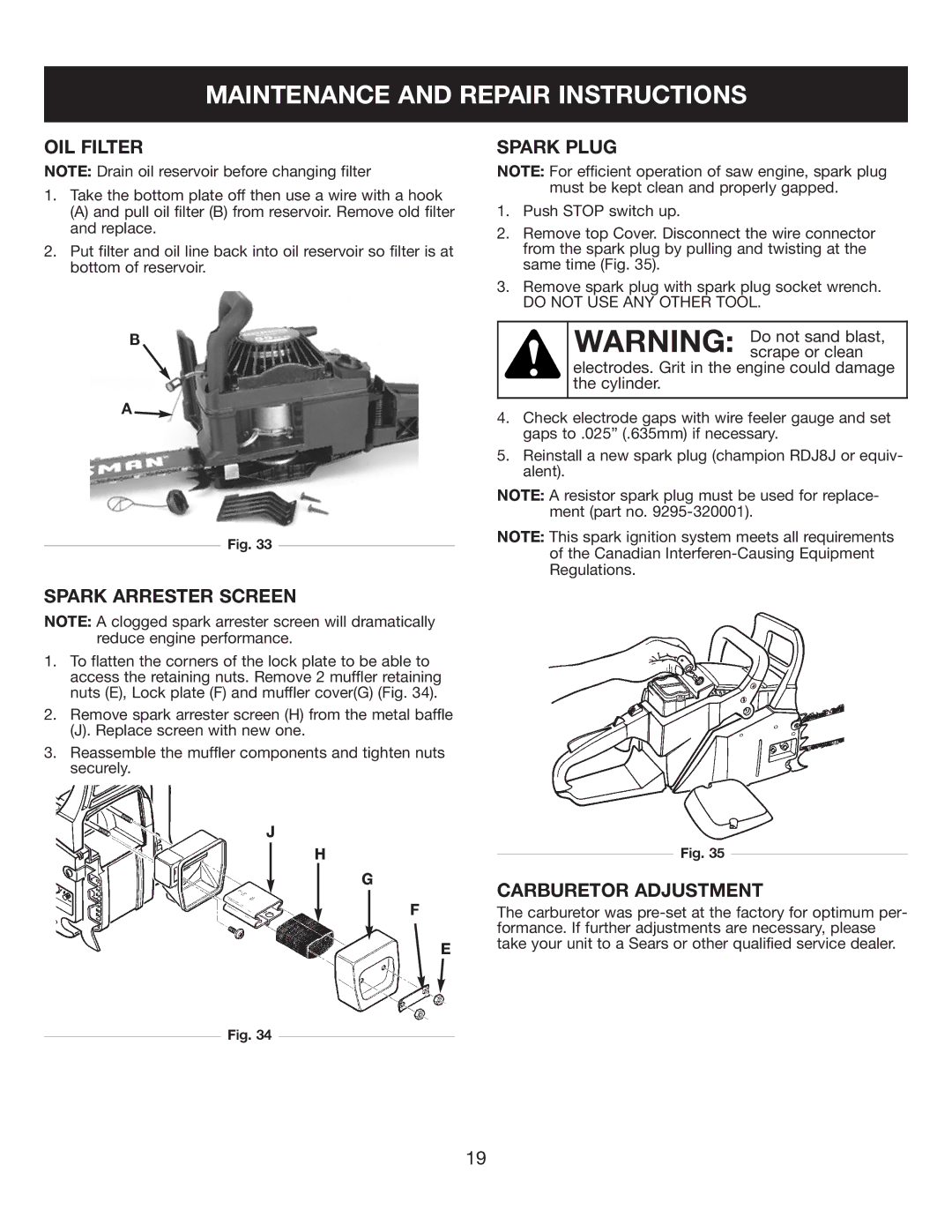

OIL FILTER

NOTE: Drain oil reservoir before changing filter

1.Take the bottom plate off then use a wire with a hook

(A) and pull oil filter (B) from reservoir. Remove old filter and replace.

2.Put filter and oil line back into oil reservoir so filter is at bottom of reservoir.

B

A![]()

Fig. 33

SPARK ARRESTER SCREEN

NOTE: A clogged spark arrester screen will dramatically reduce engine performance.

1.To flatten the corners of the lock plate to be able to access the retaining nuts. Remove 2 muffler retaining nuts (E), Lock plate (F) and muffler cover(G) (Fig. 34).

2.Remove spark arrester screen (H) from the metal baffle

(J). Replace screen with new one.

3.Reassemble the muffler components and tighten nuts securely.

J

H

G

F

E

SPARK PLUG

NOTE: For efficient operation of saw engine, spark plug must be kept clean and properly gapped.

1.Push STOP switch up.

2.Remove top Cover. Disconnect the wire connector from the spark plug by pulling and twisting at the same time (Fig. 35).

3.Remove spark plug with spark plug socket wrench.

DO NOT USE ANY OTHER TOOL.

WARNING: Do not sand blast, scrape or clean

electrodes. Grit in the engine could damage the cylinder.

4.Check electrode gaps with wire feeler gauge and set gaps to .025” (.635mm) if necessary.

5.Reinstall a new spark plug (champion RDJ8J or equiv- alent).

NOTE: A resistor spark plug must be used for replace- ment (part no.

NOTE: This spark ignition system meets all requirements of the Canadian

Fig. 35

CARBURETOR ADJUSTMENT

The carburetor was

Fig. 34

19