MAINTENANCE AND REPAIR INSTRUCTIONS

STORING A CHAIN SAW

CAUTION: Never store a chain saw for longer than 30

days without performing the following proce- dures.

Storing a chain saw for longer than 30 days requires stor- age maintenance. Unless the storage instructions are fol- lowed, fuel remaining in the carburetor will evaporate, leaving

1.Remove the fuel tank cap slowly to release any pres- sure in tank. Carefully drain the fuel tank by running the unit dry or by tipping the motor housing/fuel tank over and draining oil/fuel mixture into a container with the same

2.Start the engine and let it run until the unit stops to remove fuel from carburetor.

3.Allow the engine to cool (approx. 5 minutes).

4.Using a spark plug wrench, remove the spark plug.

5.Pour 1 teaspoon of clean

36).

NOTE: Store the unit in a dry place and away from possi- ble sources of ignition such as a furnace, gas hot water heater, gas dryer, etc.

Sprocket Tip Lubrication

CAUTION: The sprocket tip on your new saw has

been

Lubrication of the sprocket tip is recom- mended after 10 hours of use or once a week, which ever occurs first. Always thor- oughly clean guide bar sprocket tip before lubrication.

The Lube Gun (not included) is recommended for applying grease to the guide bar sprocket tip. The Lube Gun is equipped with a needle nose tip which is necessary for the efficient application of grease to the sprocket tip.

Fig. 36

REMOVING A UNIT FROM STORAGE

1.Remove spark plug.

2.Pull starter rope briskly to clear excess oil from com- bustion chamber.

3.Clean and gap spark plug or install a new spark plug with proper gap.

4.Prepare unit for operation.

5.Fill fuel tank with proper fuel / oil mixture. See Oil and Fuel Information.

GUIDE BAR MAINTENANCE

Frequent lubrication of the guide bar (railed bar which |

|

supports and carries the saw chain) sprocket tip is |

|

required. Proper maintenance of the guide bar, as |

|

explained in this section, is essential to keep your saw in |

|

good working condition. | 20 |

|

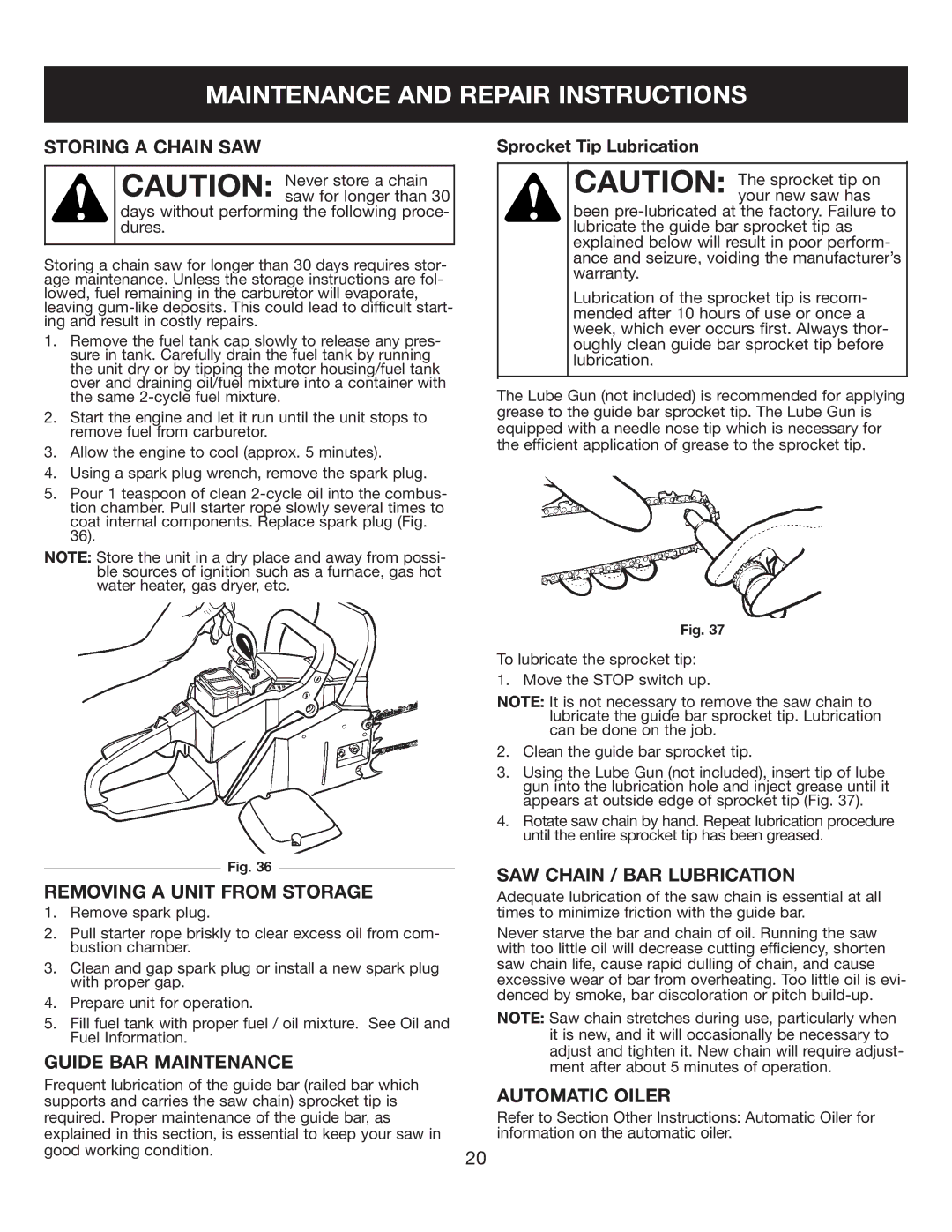

Fig. 37

To lubricate the sprocket tip:

1. Move the STOP switch up.

NOTE: It is not necessary to remove the saw chain to lubricate the guide bar sprocket tip. Lubrication can be done on the job.

2.Clean the guide bar sprocket tip.

3.Using the Lube Gun (not included), insert tip of lube gun into the lubrication hole and inject grease until it appears at outside edge of sprocket tip (Fig. 37).

4.Rotate saw chain by hand. Repeat lubrication procedure until the entire sprocket tip has been greased.

SAW CHAIN / BAR LUBRICATION

Adequate lubrication of the saw chain is essential at all times to minimize friction with the guide bar.

Never starve the bar and chain of oil. Running the saw with too little oil will decrease cutting efficiency, shorten saw chain life, cause rapid dulling of chain, and cause excessive wear of bar from overheating. Too little oil is evi- denced by smoke, bar discoloration or pitch

NOTE: Saw chain stretches during use, particularly when it is new, and it will occasionally be necessary to adjust and tighten it. New chain will require adjust- ment after about 5 minutes of operation.

AUTOMATIC OILER

Refer to Section Other Instructions: Automatic Oiler for information on the automatic oiler.