SFN1+, SFN1 specifications

The Senco SFN1 and SFN1+ are powerful pneumatic framing nailers designed for high-performance construction tasks. These models are particularly favored by contractors for their robustness, reliability, and efficiency in driving nails into various materials.The SFN1 is built to handle a wide range of applications, from framing to sheathing, and even roofing. It features a lightweight aluminum housing that ensures durability while minimizing user fatigue during extended use. Weighing in at just over 4 pounds, the SFN1 is designed for maneuverability without sacrificing power.

One of the most notable features of the SFN1 is its adjustable depth-of-drive. Users can easily modify the depth of the nails to accommodate different material types and project requirements. This feature provides precise control and ensures a clean finish, reducing the risk of damaging the workpiece.

The SFN1+ takes this functionality further by incorporating advanced technology such as a dual-action trigger, which allows users to switch between bump fire and sequential firing modes. This versatility makes it suitable for both rapid nailing and precision work. In addition, the SFN1+ boasts an enhanced magazine that holds up to 100 nails, meaning less downtime for reloading and increased productivity on the job.

Both models utilize an efficient air-powered mechanism that enables quick recovery between shots, allowing for greater firing speed without sacrificing accuracy. The SFN1 and SFN1+ are compatible with a variety of nail lengths, typically ranging from 2 to 3.5 inches, making them versatile tools for different applications.

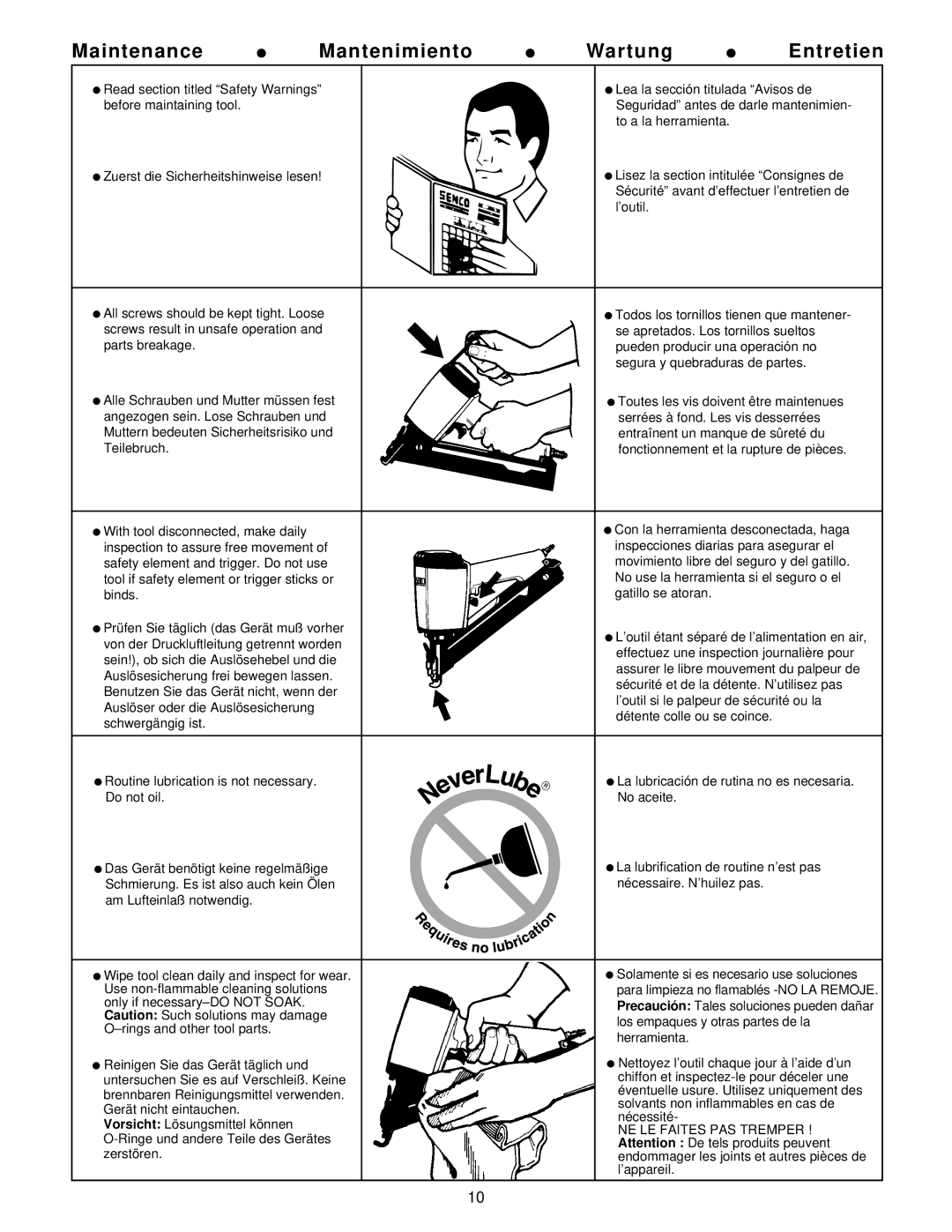

In terms of safety, both nailers come equipped with a safety mechanism that prevents accidental firing, providing peace of mind for users. The rubberized grip ensures a comfortable hold, reducing the risk of slippage during operation.

Overall, the Senco SFN1 and SFN1+ nailers represent a combination of advanced technology, durability, and user-friendly features, making them indispensable tools for professionals in the construction industry. Whether framing a house or tackling a DIY project, these nailers deliver the performance needed to get the job done efficiently and effectively. Their reputation for reliability and ease of use solidifies Senco's standing as a trusted name in pneumatic tools.