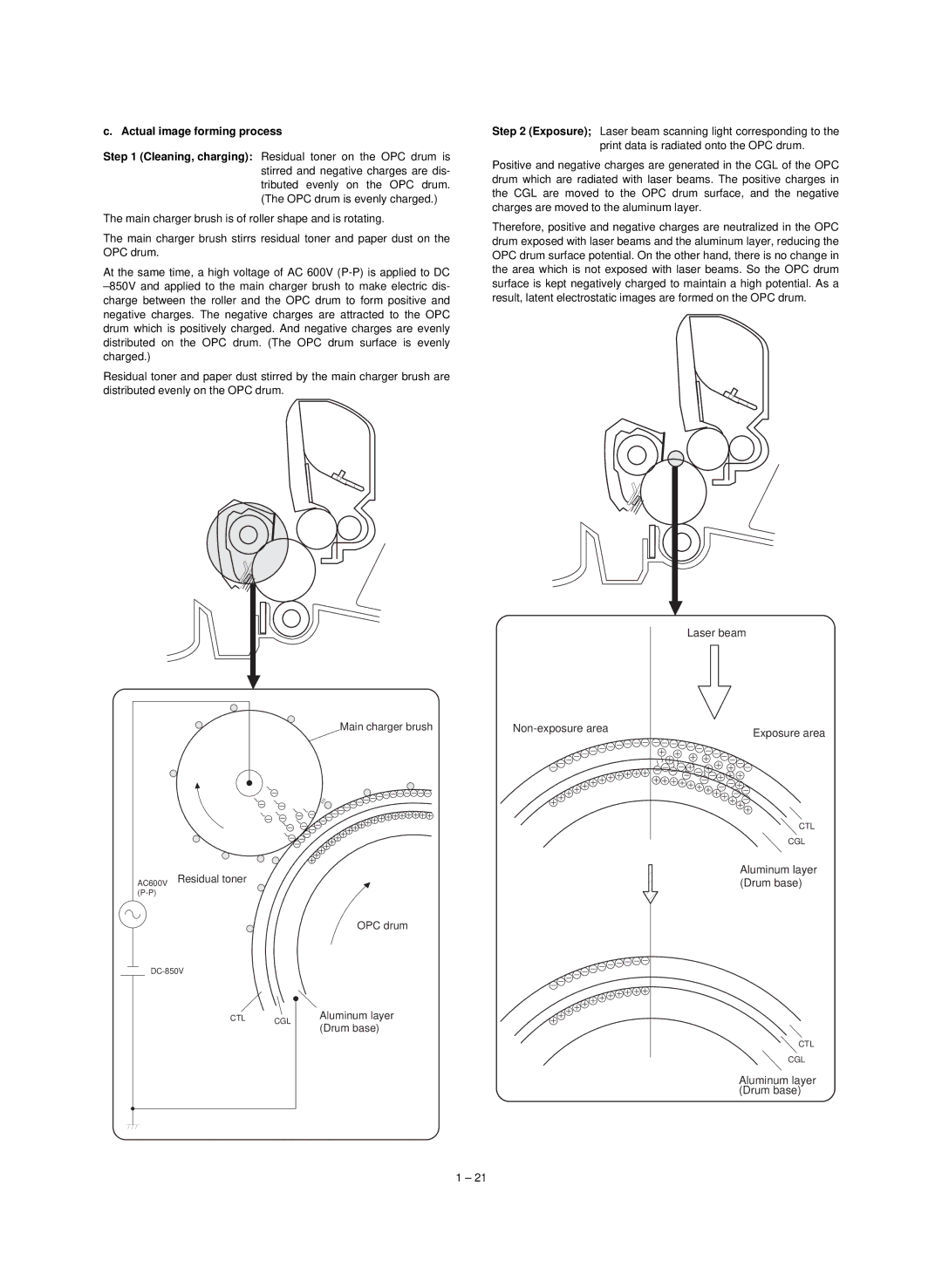

c. Actual image forming process

Step 1 (Cleaning, charging): Residual toner on the OPC drum is stirred and negative charges are dis- tributed evenly on the OPC drum. (The OPC drum is evenly charged.)

The main charger brush is of roller shape and is rotating.

The main charger brush stirrs residual toner and paper dust on the OPC drum.

At the same time, a high voltage of AC 600V

Residual toner and paper dust stirred by the main charger brush are distributed evenly on the OPC drum.

Step 2 (Exposure); Laser beam scanning light corresponding to the print data is radiated onto the OPC drum.

Positive and negative charges are generated in the CGL of the OPC drum which are radiated with laser beams. The positive charges in the CGL are moved to the OPC drum surface, and the negative charges are moved to the aluminum layer.

Therefore, positive and negative charges are neutralized in the OPC drum exposed with laser beams and the aluminum layer, reducing the OPC drum surface potential. On the other hand, there is no change in the area which is not exposed with laser beams. So the OPC drum surface is kept negatively charged to maintain a high potential. As a result, latent electrostatic images are formed on the OPC drum.

Laser beam

Main charger brush | Exposure area | |

|

|

AC600V Residual toner

CTL CGL

CTL

CGL

Aluminum layer (Drum base)

OPC drum

Aluminum layer (Drum base)

CTL

CGL

Aluminum layer (Drum base)

1 – 21