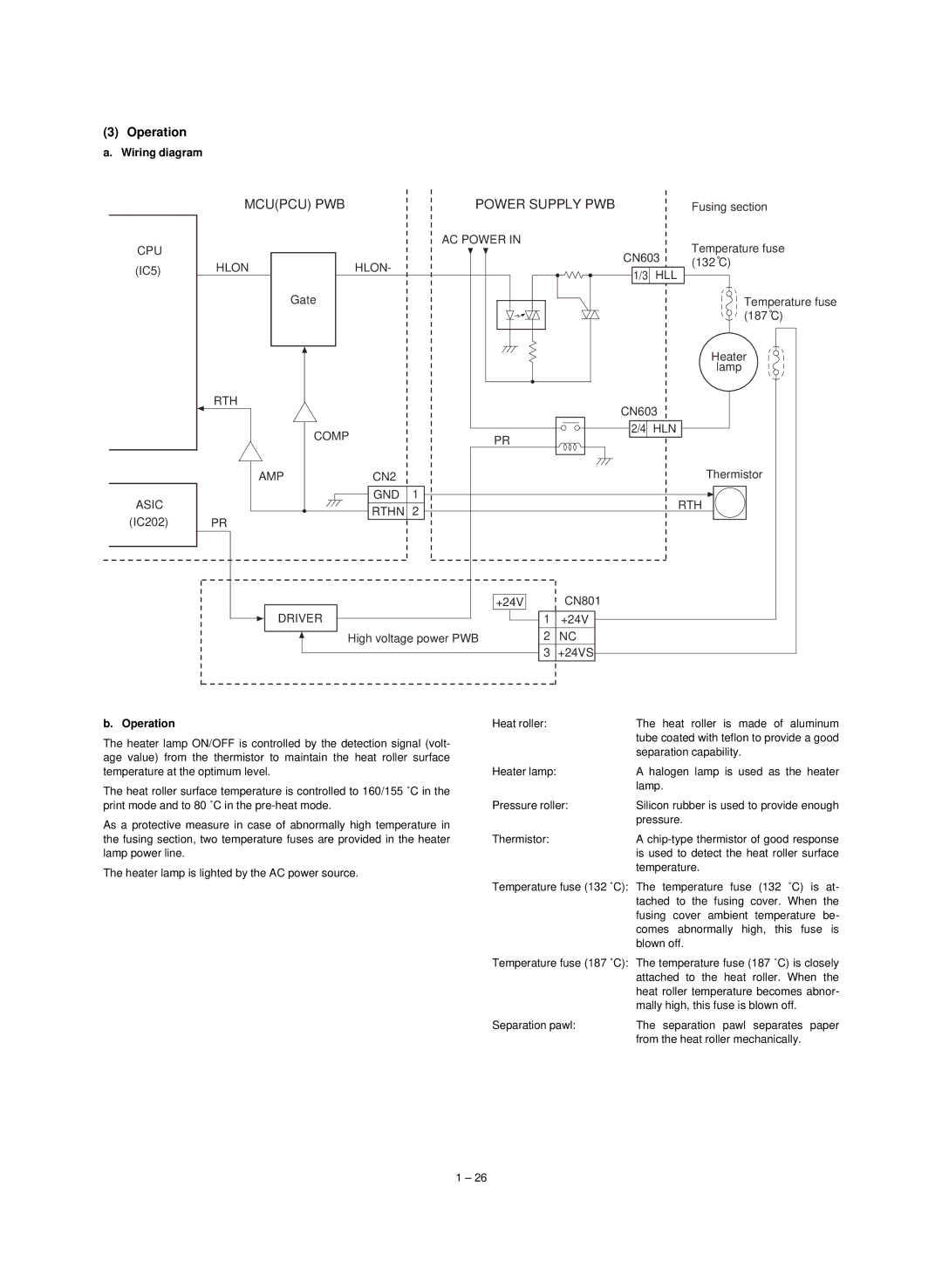

(3) Operation

a. Wiring diagram

CPU

(IC5)

ASIC (IC202)

MCU(PCU) PWB | POWER SUPPLY PWB |

| Fusing section | |

| AC POWER IN |

| Temperature fuse | |

| CN603 | |||

| (132 C) | |||

HLON | HLON- | HLL | ||

| ||||

| 1/3 |

| ||

Gate |

|

| Temperature fuse | |

|

|

| (187 C) | |

|

|

|

| Heater |

|

|

|

| lamp |

RTH |

|

|

| CN603 |

|

|

|

| |

| COMP |

| PR | 2/4 HLN |

|

|

| ||

|

|

|

| |

AMP | CN2 |

|

| Thermistor |

| GND | 1 |

| RTH |

| RTHN 2 |

| ||

PR |

|

| ||

|

|

|

| |

|

|

| +24V | CN801 |

DRIVER |

| 1 | +24V | |

| High voltage power PWB | 2 | NC | |

|

|

| 3 | +24VS |

b. Operation | Heat roller: | The heat roller is made of aluminum |

The heater lamp ON/OFF is controlled by the detection signal (volt- |

| tube coated with teflon to provide a good |

| separation capability. | |

age value) from the thermistor to maintain the heat roller surface |

| |

|

| |

temperature at the optimum level. | Heater lamp: | A halogen lamp is used as the heater |

The heat roller surface temperature is controlled to 160/155 ˚C in the |

| lamp. |

|

| |

print mode and to 80 ˚C in the | Pressure roller: | Silicon rubber is used to provide enough |

As a protective measure in case of abnormally high temperature in |

| pressure. |

|

| |

the fusing section, two temperature fuses are provided in the heater | Thermistor: | A |

lamp power line. |

| is used to detect the heat roller surface |

The heater lamp is lighted by the AC power source. |

| temperature. |

|

| |

| Temperature fuse (132 ˚C): The temperature fuse (132 ˚C) is at- | |

|

| tached to the fusing cover. When the |

|

| fusing cover ambient temperature be- |

|

| comes abnormally high, this fuse is |

|

| blown off. |

| Temperature fuse (187 ˚C): The temperature fuse (187 ˚C) is closely | |

|

| attached to the heat roller. When the |

|

| heat roller temperature becomes abnor- |

|

| mally high, this fuse is blown off. |

| Separation pawl: | The separation pawl separates paper |

|

| from the heat roller mechanically. |

1 – 26