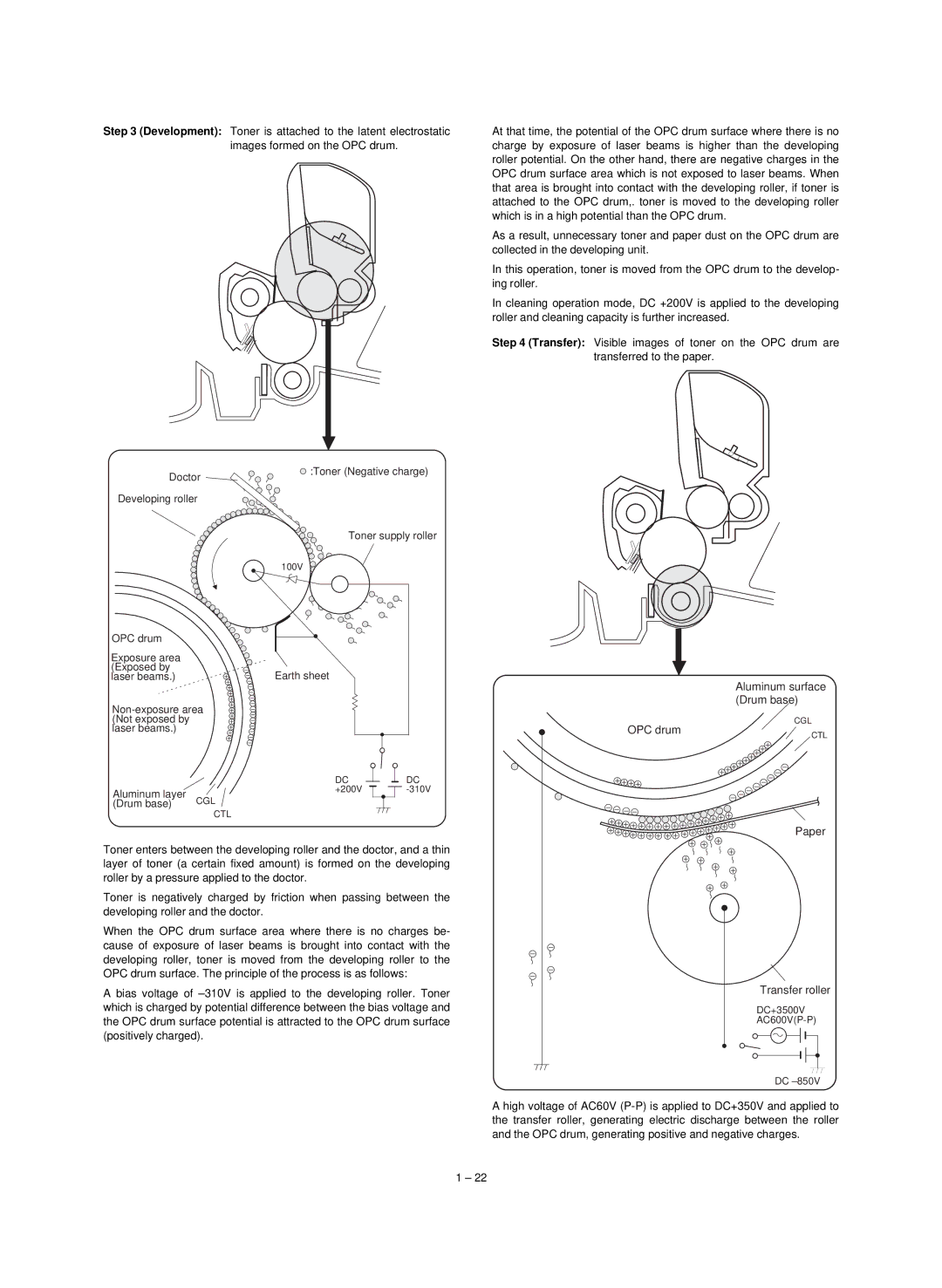

Step 3 (Development):

Doctor

Developing roller

Toner is attached to the latent electrostatic images formed on the OPC drum.

![]() :Toner (Negative charge)

:Toner (Negative charge)

Toner supply roller

100V

At that time, the potential of the OPC drum surface where there is no charge by exposure of laser beams is higher than the developing roller potential. On the other hand, there are negative charges in the OPC drum surface area which is not exposed to laser beams. When that area is brought into contact with the developing roller, if toner is attached to the OPC drum,. toner is moved to the developing roller which is in a high potential than the OPC drum.

As a result, unnecessary toner and paper dust on the OPC drum are collected in the developing unit.

In this operation, toner is moved from the OPC drum to the develop- ing roller.

In cleaning operation mode, DC +200V is applied to the developing roller and cleaning capacity is further increased.

Step 4 (Transfer): Visible images of toner on the OPC drum are transferred to the paper.

OPC drum |

|

Exposure area |

|

(Exposed by | Earth sheet |

laser beams.) |

| DC | DC |

Aluminum layer | +200V | |

CGL |

| |

(Drum base) |

|

CTL

Toner enters between the developing roller and the doctor, and a thin layer of toner (a certain fixed amount) is formed on the developing roller by a pressure applied to the doctor.

Toner is negatively charged by friction when passing between the developing roller and the doctor.

When the OPC drum surface area where there is no charges be- cause of exposure of laser beams is brought into contact with the developing roller, toner is moved from the developing roller to the OPC drum surface. The principle of the process is as follows:

A bias voltage of

Aluminum surface (Drum base)

CGL

OPC drum

CTL

Paper

Transfer roller

DC+3500V

DC

A high voltage of AC60V

1 – 22