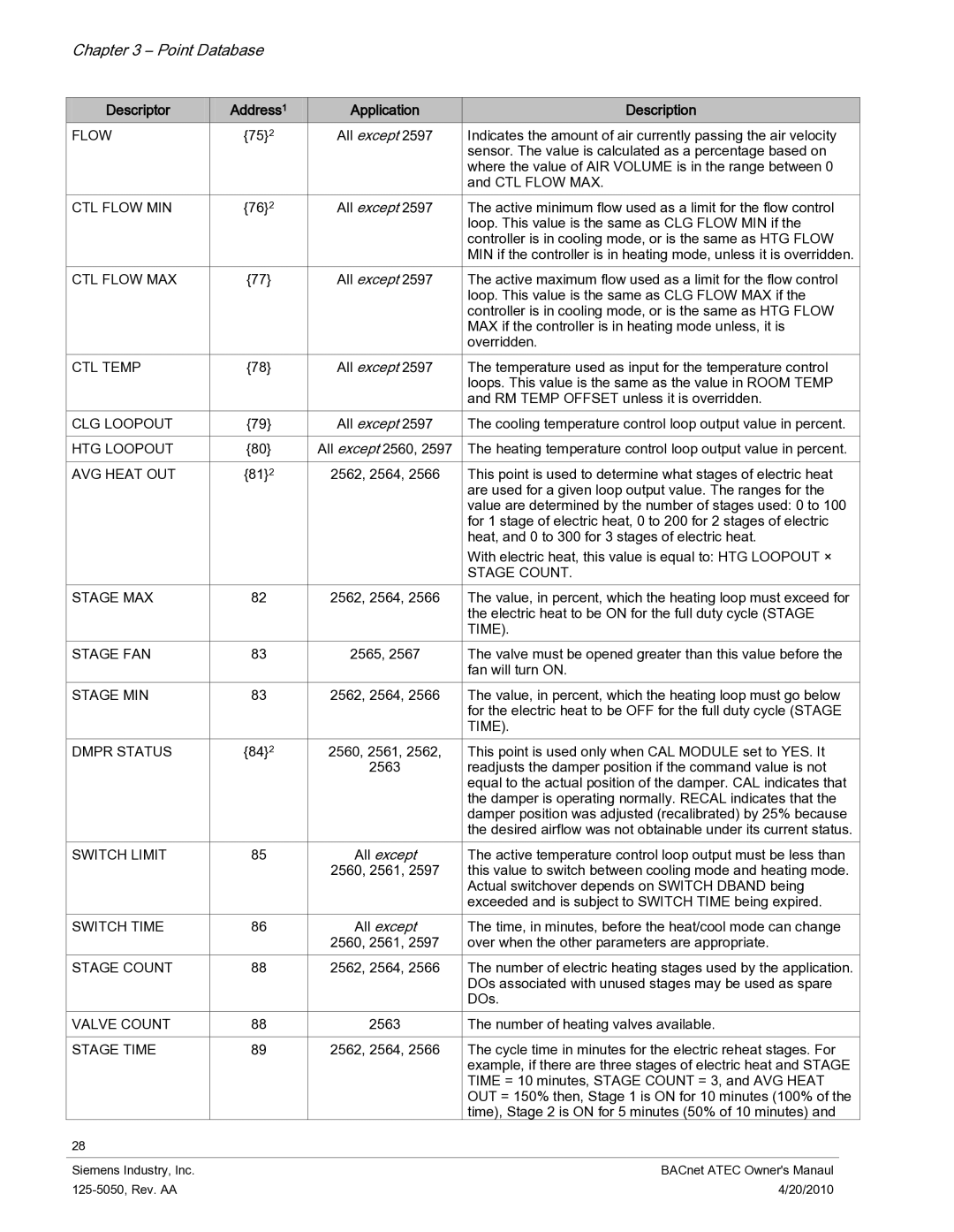

Chapter 3 – Point Database

Descriptor | Address1 | Application | Description | |

FLOW | {75}2 | All except 2597 | Indicates the amount of air currently passing the air velocity | |

|

|

| sensor. The value is calculated as a percentage based on | |

|

|

| where the value of AIR VOLUME is in the range between 0 | |

|

|

| and CTL FLOW MAX. | |

CTL FLOW MIN | {76}2 | All except 2597 | The active minimum flow used as a limit for the flow control | |

|

|

| loop. This value is the same as CLG FLOW MIN if the | |

|

|

| controller is in cooling mode, or is the same as HTG FLOW | |

|

|

| MIN if the controller is in heating mode, unless it is overridden. | |

CTL FLOW MAX | {77} | All except 2597 | The active maximum flow used as a limit for the flow control | |

|

|

| loop. This value is the same as CLG FLOW MAX if the | |

|

|

| controller is in cooling mode, or is the same as HTG FLOW | |

|

|

| MAX if the controller is in heating mode unless, it is | |

|

|

| overridden. | |

CTL TEMP | {78} | All except 2597 | The temperature used as input for the temperature control | |

|

|

| loops. This value is the same as the value in ROOM TEMP | |

|

|

| and RM TEMP OFFSET unless it is overridden. | |

CLG LOOPOUT | {79} | All except 2597 | The cooling temperature control loop output value in percent. | |

|

|

|

| |

HTG LOOPOUT | {80} | All except 2560, 2597 | The heating temperature control loop output value in percent. | |

|

|

|

| |

AVG HEAT OUT | {81}2 | 2562, 2564, 2566 | This point is used to determine what stages of electric heat | |

|

|

| are used for a given loop output value. The ranges for the | |

|

|

| value are determined by the number of stages used: 0 to 100 | |

|

|

| for 1 stage of electric heat, 0 to 200 for 2 stages of electric | |

|

|

| heat, and 0 to 300 for 3 stages of electric heat. | |

|

|

| With electric heat, this value is equal to: HTG LOOPOUT × | |

|

|

| STAGE COUNT. | |

STAGE MAX | 82 | 2562, 2564, 2566 | The value, in percent, which the heating loop must exceed for | |

|

|

| the electric heat to be ON for the full duty cycle (STAGE | |

|

|

| TIME). | |

STAGE FAN | 83 | 2565, 2567 | The valve must be opened greater than this value before the | |

|

|

| fan will turn ON. | |

STAGE MIN | 83 | 2562, 2564, 2566 | The value, in percent, which the heating loop must go below | |

|

|

| for the electric heat to be OFF for the full duty cycle (STAGE | |

|

|

| TIME). | |

DMPR STATUS | {84}2 | 2560, 2561, 2562, | This point is used only when CAL MODULE set to YES. It | |

|

| 2563 | readjusts the damper position if the command value is not | |

|

|

| equal to the actual position of the damper. CAL indicates that | |

|

|

| the damper is operating normally. RECAL indicates that the | |

|

|

| damper position was adjusted (recalibrated) by 25% because | |

|

|

| the desired airflow was not obtainable under its current status. | |

SWITCH LIMIT | 85 | All except | The active temperature control loop output must be less than | |

|

| 2560, 2561, 2597 | this value to switch between cooling mode and heating mode. | |

|

|

| Actual switchover depends on SWITCH DBAND being | |

|

|

| exceeded and is subject to SWITCH TIME being expired. | |

SWITCH TIME | 86 | All except | The time, in minutes, before the heat/cool mode can change | |

|

| 2560, 2561, 2597 | over when the other parameters are appropriate. | |

STAGE COUNT | 88 | 2562, 2564, 2566 | The number of electric heating stages used by the application. | |

|

|

| DOs associated with unused stages may be used as spare | |

|

|

| DOs. | |

VALVE COUNT | 88 | 2563 | The number of heating valves available. | |

|

|

|

| |

STAGE TIME | 89 | 2562, 2564, 2566 | The cycle time in minutes for the electric reheat stages. For | |

|

|

| example, if there are three stages of electric heat and STAGE | |

|

|

| TIME = 10 minutes, STAGE COUNT = 3, and AVG HEAT | |

|

|

| OUT = 150% then, Stage 1 is ON for 10 minutes (100% of the | |

|

|

| time), Stage 2 is ON for 5 minutes (50% of 10 minutes) and | |

28 |

|

|

|

|

|

|

|

|

|

Siemens Industry, Inc. |

|

| BACnet ATEC Owner's Manaul | |

|

| 4/20/2010 |

| |