Teleperm m

Related catalogs

Automation and Drives

AS 488/TM automation systems

Introduction

AS 488/TM

Teleperm M Process Control System

Overview

Introduction

Teleperm M Process Control System

Automation systems

Engineering

System bus

Migration strategy

AS 488/TM

Limitations in communication

Highlights

Classification in the Teleperm M system environment

Non-migratable systems

Area of application

Functions Highlights

System software

System architecture

System properties

Commissioning

System architecture

System properties

Functions

Technical Specifications Quantity breakdown

AS 488/TM CPU

Standard function blocks

System software

User function blocks

Optional function blocks

Blocks for analog and digital processing

Configuration

Listing of Teleperm M standard function blocks Data blocks

Blocks for binary processing

AKS

PKM

PKF

AKE

Blocks for PLC/PLC coupling with PROFIBUS-AG/AG

Type Name Function Interface

Type Name Function For modules with Order No

Blocks for I/O modules with standardized display

Organization blocks

Test blocks

Cable for connection of the commissioning terminal

Commissioning

Commissioning terminal

If 962-COM serial interface module

Engineering with Prograf AS+

Bus connection

Technical Specifications Hardware requirements

Software requirements

Automation systems released for Prograf AS+/NT

Accessories

PC components ISA for connection to Teleperm M system bus

PC components PCI for connection to Teleperm M system bus

System architecture

AS 488 S Cabinet system

AS 488 S cabinet system

AS 488 S cabinet system

Cabinet system

AS 488 S

Scope of delivery of AS 488 S systems

Connection to CS 275 system bus with versions 5 to

Power supply

Cables for connection of two I/O buses with versions 1

System software

Log IK PI

Teleperm M 19 cabinets

6DS9 207-8AA

AS 488 K Compact system

AS 488 K compact system

AS 488 K compact system

Compact system

AS 488 K

Overview Ordering Data

Teleperm M I/Os connection

Connection to CS 275 system bus

Bus components for single CS

Bus components for redundant CS

Each 6DS4 400-8AB 6DS9 203-8CA

AS 488 in Simatic design

Introduction

Technical Specifications

AS 488 in Simatic design

Introduction

ET 200U

Coupling to other systems with DP interface

Coupling to PROFIBUS-PA

ET 200B

Monitoring

Central processing unit

Overview CPU

CPU

Power supply modules

PS 405 and PS 407 load power supplies

Backup battery

If 964-DP interface module

Connection of distributed I/Os

EXM 478 expansion module 6ES7 478-2AC00-0AC0

DP2-INI initialization C79451-A3496-D900

Connection to Teleperm M I/Os

Connection to CS Connection to PROFIBUS-TM

TPM 478 interface module 6ES7 478-2DA01-0AC0

EXM 478 expansion module

Packaging system

Overview UR2 rack

Migration rack

Additional configuring tools

System software, documentation

Simatic PCS 7 cabinet design

Simatic PCS 7 cabinet design

Cabinet packaging system

Electrical design

Basic cabinet

Mechanical design

Options for the electrical design

ET 200M I/O unit

Power supply

Load power supply for I/O modules

Hot swapping

AS 488/TM system unit

Simatic PCS 7 cabinet design

Migration of existing systems

Migration packages

Migration of existing systems

Migration of existing systems

General marginal conditions

Migration packages

Scope of delivery and services

Additive supplementary components and services

AS 488 S migration package

General marginal conditions/limitations

AS 488 S migration package

AS 488 K migration package

AS 488 K migration package

GWK-PAS-AS-UPAK488

MIG I migration rack

Configuration possibilities for I/Os

MIG II migration rack

MIG K migration rack

Retrofitting services

Check list prior to retrofitting

Configuring lists

Migratable Teleperm M modules in AS 488/TM

Migratable Teleperm M modules in AS 488/TM

Binary calculation modules

Explanations for the column „Remarks

Explanations for the column „Release

Coupling modules

Migration of existing systems

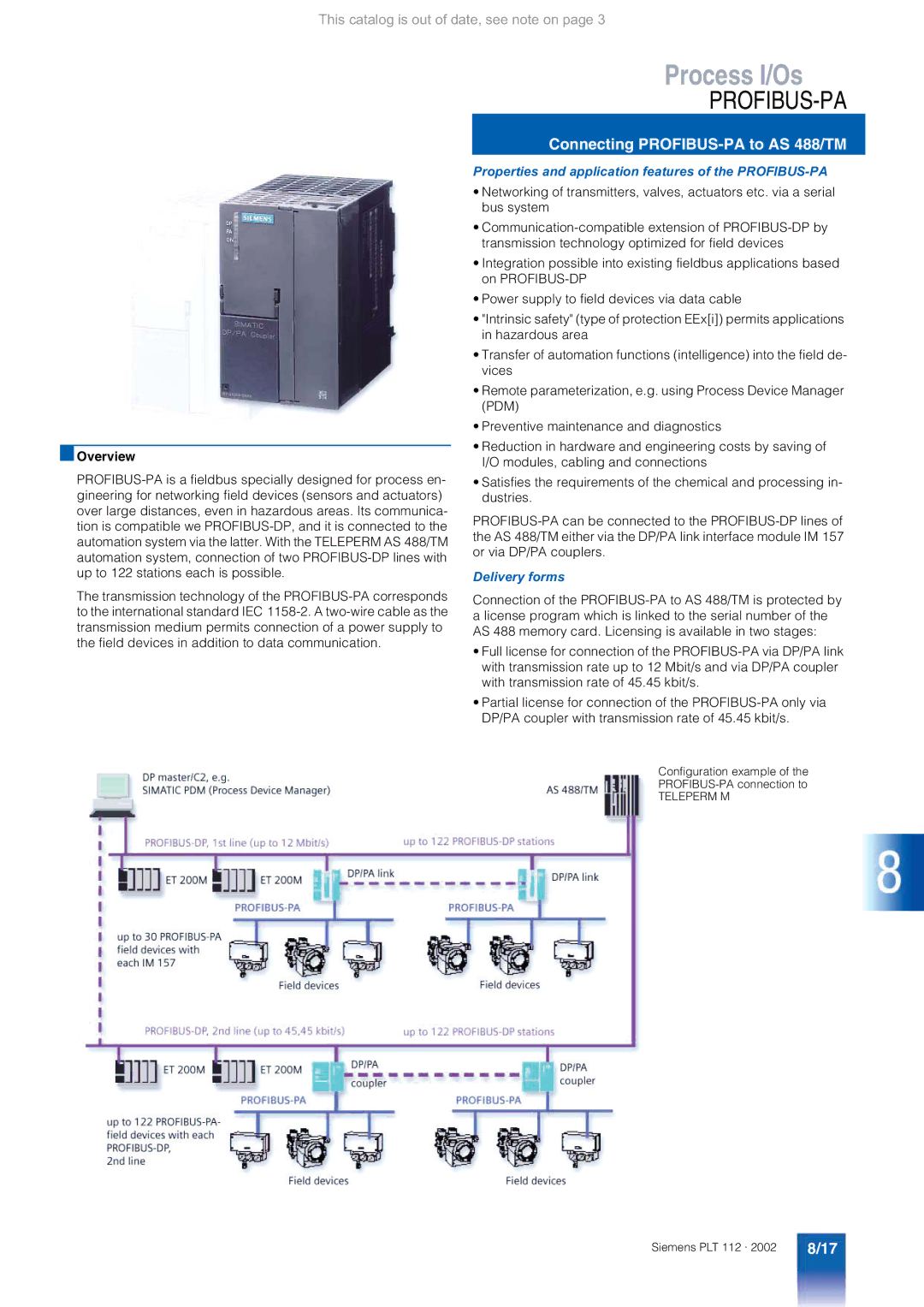

Connecting PROFIBUS-PA to AS 488/TM

Process I/Os

ET 200M packaging system

Process I/Os

TBX 478 interface module 6ES7 478-2DX00-0AA0

Connecting Teleperm M I/Os

TBX 478 interface module

Set of ribbon cables C79451-A3496-D2

Connecting Simatic I/Os

Interface module for connection to PROFIBUS-DP

Communication via the PROFIBUS-DP fieldbus

COM Profibus

PROFIBUS-DP quantity breakdown

Mode of operation

DP extensions for AS 488/TM

Driver blocks

ET 200M packaging system

ET 200M

Simple packaging system with bus connectors

Components for both packaging systems

ET 200M modules

SM 323 digital input/output modules Inputs, 8 outputs

Temperature range Inputs, 16 outputs

Temperature range Inputs, 14 bit, 20 ms conver

Inputs, 8 outputs, extended

Intrinsically-safe equipment which can be connected

Ex I/O modules

Ex digital input/output modules EEx ib

Ex analog input/output modules EEx ib

Function and communications modules

ET 200S

Configuration limits when used on AS

Configuration and parameterization

ET 200S

6ES7 134-4LB00-0AB0

6ES7 134-4FB00-0AB0

6ES7 134-4FB50-0AB0

6ES7 134-4GB00-0AB0

ET 200B

ET 200X, ET 200U and ET 200B

ET 200U

IP 262 closed-loop control mod- ule

Configuration Siwa driver block

Siwarex M

Delivery forms

Connecting PROFIBUS-PA to AS 488/TM

Properties and application features of the PROFIBUS-PA

Teleperm M

Driver block Description

Connection of PROFIBUS-PA using DP/PA coupler

Connection of PROFIBUS-PA using DP/PA link

PROFIBUS-PA

IM 157 interface module for 6ES7 157-0AA81-0XA0 DP/PA link

Technical Specifications Ordering Data

Technical data DP/PA link IM DP/PA coupler Only

AS x88/TM-PA coupling soft 6DS5 130-8AA Ware, full license

Process I/Os

Bus communication

CS-L2 bridge

Bus communication

Transmission systems

Bus connector

Electrical bus terminal

Optical link module

Optical bus terminal OBT for Profibus

Transmission media

Configuring

TPM 478 interface module

In-house remote bus cable

Standard remote bus cable V45466-D21-B35

Length ..... m

Remote bus cable with addi- tional armoring

CS-L2 bridge

CS-L2 bridge

CS-L2 bridge

Configuration Station addresses

Performance data

PROFIBUS-TM

Central processing unit

PS 405 load power supply, 10 a 6ES7 405-0KA01-0AA0

Connection to PROFIBUS-TM Connection to CS

If 964-DP interface module 6ES7 964-2AA01-0AB0

TPM 478 interface module

Ordering Data Overview

Data couplings with other systems

Introduction AG-AG coupling software Serial coupling

10/2

Data couplings with other systems

Data couplings

Coupling with systems from other vendors

10/3

System couplings

AG-AG coupling software

AG/AG coupling with Simatic S5/S7 central controllers

AG/AG coupling software 6DS5 124-1AA

10/4

PROFIBUS-AG/AG

SDA

10/5

Direct couplings

Serial coupling

Transmission rate Max. cable length

10/6

Appendix

Software

Appendix

Software licenses

11/2

Information and order option

Internet and on CD-ROM

11/3

Internet

Internet, Training

11/4

Training Courses in the Training Center Karlsruhe

Order No. index

11/5