USER’S Manual

Table of Contents

Electrical Installation Hazardous Area Installation

Mechanical Installation

ON-LINE Operation

OFF-LINE Operation

6.1

Section and Title

List of Illustrations

List of Tables

Changes for Issue 1, October

Page

Contents

Introduction

Section Contents

Basic Model

MXC

Product Description

Product Support

Configuration

XTC Communicator

OFF

Keypad Description

Display

Dedicated Keys

XTC Communicator

Function Keys

Loop Connection

MXC Software Version

Power

MXC Menu Screens and Parameter MAP

Major MXC Menu Screens

Parameter Map, MXC/Model

XTC Communicator

Commissioning Transmitter on the Bench or in the Field

Initial Transmitter SET-UP

Test Equipment Needed

Test Equipment

Bench Test Connections

Establishing Communication

Enter Transmitter

MXC Testing

Testing the TRANSMITTER, MXC, and the Loop

Initial Transmitter SET-UP

Transmitter Testing

Review Configuration Data

Loop Testing

Transmitter Function Blocks Sensor Input

Pusp

Checking Transmitter Output

Initial Transmitter SET-UP

Equipment Delivery and Handling

Installation

Factory Shipment

Receipt of Shipment

Environmental Considerations

Installation Considerations

Mechanical

Operating Mode and Network

Transmitter Operating Mode and Network Type

Electrical

Digital Mode

Analog Mode

Network for Non-Hazardous Locations See 250

Point-To-Point Network Analog Mode

Multi-Drop Network Digital Mode

Operating

Power Supply Requirements

Multi-Drop Network

Point-To-Point Network

Cable Capacitance

Cable Capacitance and Maximum Length

Maximum Cable Length Calculation

Network Junctions

Field Instrument Capacitance

Connection of Miscellaneous Hardware

Safety Barriers

Determine Sensor Cable Requirements

10 2-Wire RTD Accuracy Limitation

Shielding and Grounding

Pipe Mounting

Mechanical Installation

Installation

Dimensions, Mounting Bracket for Model

X02822S0

Model 344 Mounting Configurations with Supplied Bracket

Flat Surface Mounting

Direct Mounting to Process

Transmitter-To-Process Mounting

Sensor Assembly

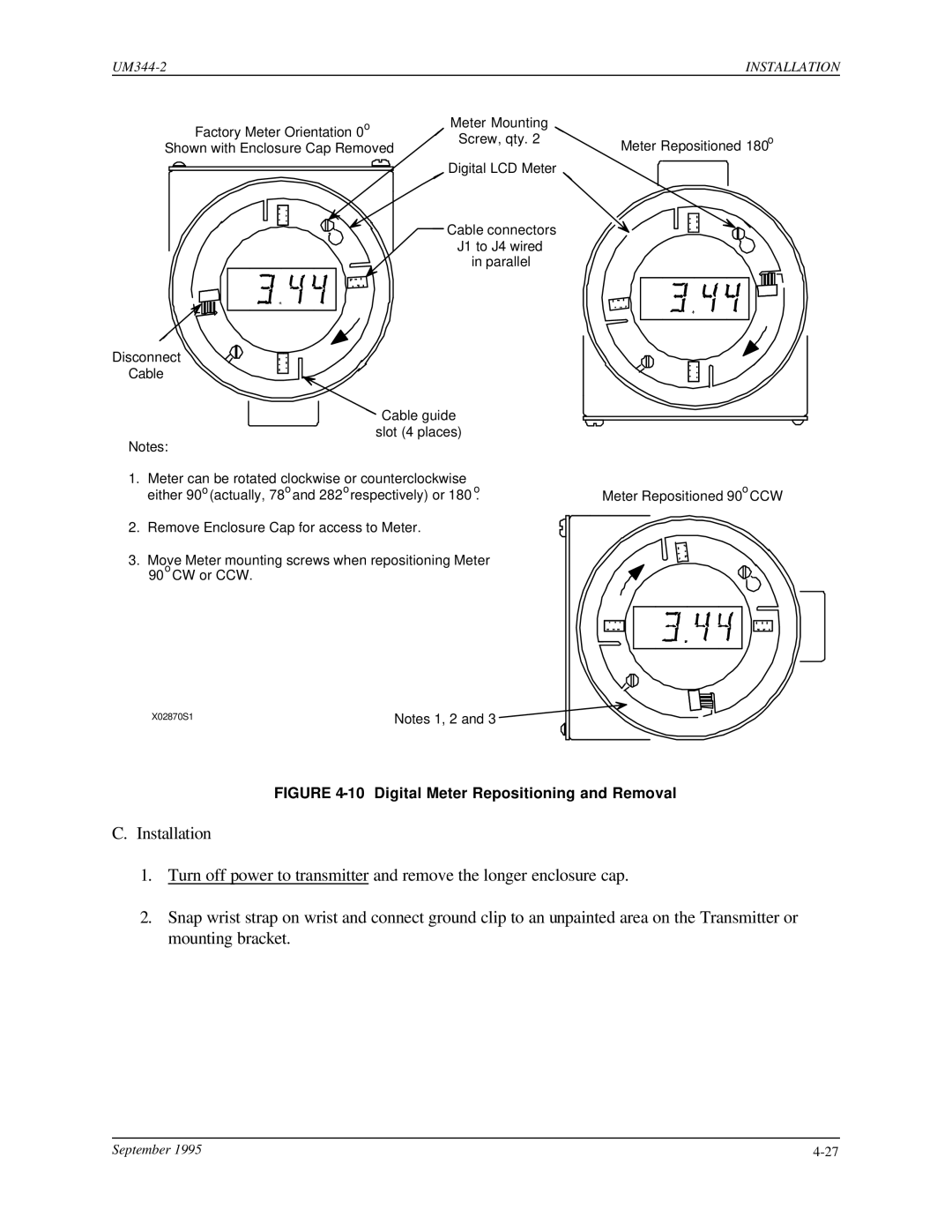

Local Digital Meter Installation, Repositioning and Removal

Digital Meter Orientation and Mounting Hardware

10 Digital Meter Repositioning and Removal

Conduit

Electrical Conduit and Cable Installation

11 Conduit Drain and Explosion Proof Installations

Cables

Access to Transmitter Terminal Compartment

Electrical Installation

12 Signal Loop , Sensor, MXC and Test Terminals

13 Model 344 Sensor Wiring

Thermocouple And Extension Grade Wire Characteristics

EXPLOSION-PROOF Installation

Hazardous Area Installation

Installation

ON-LINE and OFF-LINE Operation

Using the MXC for Configuration

ON-LINE Operation

V I D 2 1 0 3 0 0 0 0 3 C Tag TTC 101 ADD

Sensor Input Block

Method 1 The Tell

Operator Display Block

Transmitter ID Block

Output Block

Alarm Block

ON-LINE and OFF-LINE Operation

1.7 A/M Transfer Block

Setpoint Track and Hold Block

Controller Block

End or Review Configuration

Select Block to Edit Sensor Input Prev Next END SEL ECT

Downloading a Configuration

ON-LINE and OFF-LINE Operation

Local Pushbutton Operation

Local Transmitter Operation

ENG

Display Functions

CEL, OHMS, MV, KELV, RANK, Fahr

ON-LINE and OFF-LINE Operation

Ranging Controller OFF

ON-LINE and OFF-LINE Operation

Local Pushbutton

Damping Adjustment Controller

OFF

AUTO/MANUAL, Setpoint

Valve Adjustments Controller

UM344-2 August

ON-LINE and OFF-LINE Operation

ON-LINE and OFF-LINE Operation

Quick Access Key Operation

Enter Zoom Value END TER

NEW Setpoint

OFF-LINE Operation

Using Off-Line Operations to Access an Archive

ERROR! Archive Type Doesnt Match the Transmitter Type Cont

Using an Archive in On- Line Memory

ON-LINE and OFF-LINE Operation

Press END to return to the previous screen

ON-LINE and OFF-LINE Operation

Calibration

Calibration and Maintenance

Equipment Required

Transmitter Normally Configured for Analog Mode

Transmitter Analog Output DAC Calibration

Pressing Enter will SET Transmitter Output to

Field Calibration Connections

Transmitter Normally Configured for Digital Mode

3.1 RTD/OHM Calibration Check

3 RTD/OHM Type Input Calibration

Press Cont F4. MXC will display

Calibration and Maintenance

Press Cont F4 to calibrate

Thermocouple/Millivolt Calibration Check

Thermocouple/Millivolt Type Input Calibration

Calibration and Maintenance

Narrow Millivolt Calibration

Narrow/Wide Millivolt Calibration

Wide Millivolt Calibration

Apply 103.00 mV to mV+ 1 and mV-3

Tool and Equipment Requirements

Preventive Maintenance

Transmitter Exterior Inspection

Transmitter Exterior Cleaning

Transmitter Enclosure Interior Inspection

Preliminary Troubleshooting

Troubleshooting

Transmitter Calibration

Diagnostic Messages

Troubleshooting

MXC

Self-Diagnostics Troubleshooting

Message No Transmitter Found

Communication Warning Messages

Possible Cause Corrective Action

Message No Transmitter Found

Message Communication Error

Symptom Zero or Low Output

Possible Transmitter Output Problems

Message Field Device Malfunction

Symptom High Output

Possible Cause Corrective Action

Diagnosing a Defective Digital LCD Meter

Symptom Erratic Output

NON-FIELD-REPLACEABLE Items

Enclosure Thread Lubrication

Electronics Module Removal and Replacement

Assembly Removal and Replacement

Replacement

Removal

Recommended Spare and Replacement Parts

Maintenance Records

Product Support

Software Compatibility

Return Shipment

Material Safety Data Sheet

To Return Equipment

Packaging

Calibration and Maintenance

Circuit Description

Electronics Assembly

Model 344 Electronics Module Block Diagram

Thermocouple/Millivolt TC/mV Input

Theory of Operation

2 RTD/OHMS Input

Analog Switch is turned on enabling the 52 μA sink circuit

Communication Format

Signal Conversion

Model Designation

Model Designation and Specifications

Model 344 Model Designation

General Accessories

Accessories

Thermal Sensors

Model Designation and Specifications

Typical TC and RTD Thermowell Assemblies without Heads

Thermocouple Wire

Functional and Performance

Specifications

Sensors Type, Range, Span, and Accuracy

Model Designation and Specifications

Digital Accuracy + D/A Converter Accuracy

Two-Wire Cable

Environmental

Sensor Inputs

Baseefa

Hazardous Area Classification

Model Designation and Specifications

Model Designation and Specifications

Precautions English

CSA Hazardous Locations Precautions

Précautions Français

Model Designation and Specifications

Glossary

Glossary

Glossary

Glossary

Glossary

Sensor Input Block

Appendix a Function Block Descriptions

RTD PT 100 OHM DIN, PT 100 OHM US

Operator Display Block

DD/MM/YY

Transmitter ID Block

Output Block

Setpoint Track and Hold Block

Alarm Block

A/M Transfer Block

PID/PD/ID

Controller Block

Auto

Manual

PD Controller

ID Controller

If MRT = YES

Sensor Input Block

Function Block Summary

RTD

Operator Display Block

Ascii character tag e.g., CEL, Fahr

Transmitter ID Block

Alarm Block

Output Block

SP Track & Hold Block

Temperature Controller Function Blocks

Appendix a Function Block Descriptions

Appendix B Hazardous Area Installation Drawings

Appendix B Hazardous Area Installation Drawings

Appendix B Hazardous Area Installation Drawings

Figure B-2 Model 344, Barrier Selection Dwg -3441, Sheet 2

Appendix B Hazardous Area Installation Drawings

Appendix B Hazardous Area Installation Drawings

Appendix B Hazardous Area Installation Drawings

Moore Products CO

Warranty

Warranty

Parts List

XTC Model 344 Temperature TRANSMITTER-CONTROLLER

Additional Material

Involved USER’S Manual

Hart

Ex N Installation Condition