Gina

Comments Suggestions Corrections

Gina

Copyright and Trademarks

Page

Page

Related publications Index

Page

Contents

Configuring T-ORB for BEA T Uxedo 155

217

193

203

213

Gina V4.0 System Administrator Guide September

About this manual

Introduction

Documentation on Gina

Structure of this manual

Gina Introductory Guide

Ordering manuals

Gina Reference Manual Persistency Service

Gina Developer Manual

Gina Reference Manual T-ORB

Notational conventions used in this manual

GException eliminated

Interface cancelations

Entering special options in the mgen2 and mdiff generators

Runtime libraries under WindowsNT

Mgen2 Column aliases mnemonics for SQL and PS-DB-API

Revisions

Replacement of idlgen by idlgen1

Revisions

Installation and deinstallation

Requirements

Delivery package

Scope of supply and structure of Gina

Licensing of Gina

Installing licenses

Structure of the license file

Example

Template Comment Scr

Directory structure

Installation

Unix Solaris, Sinix

Unix / HP-UX

Windows NT

Compiling and linking, Special features under Windows NT

Removing TPStartShut.o

HP-UX

GINA.PAX

4 BS2000

START-POSIX-SHELL

Using the T-ORB on basis of BEA Tuxedo

Using the T-ORB on basis of openUTM

Environment variables

Informixserver

Implementation of the Persistency Service

Clientlocale

Deinstallation

Windows NT

Windows95/98

Availability, restrictions

Unix with CFront compilers

WindowsNT

BS2000/OSD

Application variants

Creating Gina applications

Environment

Generators

Makefiles

Setting up the database

Configuring the Persistency Service

Gina V4.0 System Administrator Guide September

Customizing the database layout

Layout of the description file

Pfx file

Tbl file

Resource

Fr myClassname1 Dbspace1 Fr myClassname1 Dbspace2

Example

MyClassname hubert Insert

On Sinix

Further options

UuserName

Customizing the database layout

Overview

Configuring T-ORB for openUTM

Connection parameters

System-wide settings

Host-specific parameters

Application-specific parameters

Gina V4.0 System Administrator Guide September

Address

Admin

Configuration language

Statements

Load = Static

Access = Direct Indirect OSUNIX, Oswinnt

Application

Area

Asynpriorityrelative Absolute Equal

Asynpriority

Gina V4.0 System Administrator Guide September

Bcamappl

Cancel

Bestbcamappl

Connect

Check

Cycle

Dynamicconnect

Cyclicorder

Taapplication

Cyclictime

Foreignapplication

Cycle Check Cancel

Eventcontrol

Eventcontrol

Host

Foreignsession

MAP=

System

Keyvector

Import

Inconverter

Internetaddress

Scope = Group Global

Access = Read Write

MAX

Mpool

Operatingsystem

Netaccess

SINGLE-THREADED

MULTI-THREADED

Priorities

Portaddresses

Priorities

LOW

PRIO7 ,TIMER ,EVENT ,CYCLIC ,PGWT Schedule

Priority

Medium

Repository

Remote

Rereadtime

Schedule

Rmxa

Schedule Priorities

Session

Parameter Minimum value Maximum value

Shrtmax

Longmax

Start

Sessionpoint

Startvalue

Startrm

Syncpriority

Freesync parameter

Taapplication

System

Gina V4.0 System Administrator Guide September

DGS

Lexical structure

Syntax

Configuration language

Bbclose

Bbopen

Address Sbopen

Foreignapplicationnumber Sbopen Number Sbclose

Operatingsystem Sbopen Letter Sbclose

Eventcontrol Bbopen

Cyclictime Sbopen

Number Comma

Number Sbclose

Netaccess Sbopen Number Sbclose

Cancel Sbopen

Netaccess Sbopen Letter Comma Letter Sbclose

Netaccess Sbopen Letter Sbclose

Equal

Import Sbopen Letter Sbclose

Relative

Absolute

Sbclose

Timer Event Cyclic Pgwt

Comma Pgwt Sbclose

Number Comma Letter Sbclose

Class Sbopen Number Comma Number Comma

Comma Syncwait

LOW Medium High

Rereadtime Sbopen Number Sbclose

Taapplstatementlist

Letter Equal Letter

Rmxa Sbopen Letter Comma Letter Sbclose

MAX Sbopen Letter Comma Letter Sbclose

MAX Sbopen Letter Equal Letter

Host Sbopen Letter Comma Letter Comma Letter

Host Sbopen Letter Comma Letter

Dynamicconnect Sbopen Sbclose

Sbopen Number Comma Number Comma Number Sbclose

Letter

Sbopen

Letter Comma

Bestbcamappl

Letter Comma /* userid Letter /* passwd

Keyvector Sbopen Number Comma Number

Letter Comma Letter Sbclose

Portaddresses Sbopen Number Comma

Inconverter Sbopen Number Sbclose

Session Sbopen Letter Comma Mapsystem Sbclose

Number Comma Number Comma Number Sbclose

Address Sbopen Letter Comma Letter Sbclose

Pgpoolfs

Revision generation

Prerequisites

KDCFILE, Double

Performing the revision generation

STARTRMINFORMIX,APPLICATION

Sample configuration file

MAXASYNTASKS,4

RMXAINFORMIX,C

INTERNETADDRESS192.200.94.4

SESSIONLU6.1

CONNECT1,1, 1,6 CONNECT1,6, 1,3

Call and options

Generated files

Model of the directory structure as created by config

Configuration process of the external openUTM application

Runtime option Tnsx configuration

Gina.config

Generated files for Unix hosts

Development option

Gina.dynamic

Start and administration scripts

Configuration data for the transaction monitor

Generated files for WindowsNT hosts

Procedure for openUTM administration 100

Runtime option

Generated files for BS2000/OSD hosts

File structure for the sample

Example

Open UTM

Creating a configuration file using WinConfig

Calling WinConfig

Elements of the graphical user interface

WinConfig Main window with a sample configuration

Creating a configuration file using

107

WinConfig main window with open dialog boxes

109

Unix , Winnt , BS2000

Parameter name Value Default Statement

Host edit window

Host

Keyvector

Portaddresses

Dialog window Non-TA application parameters

Editing TA application parameters

Application

User-friendly name of the TA appli None

Dialog window Foreign application parameters

Editing foreign application parameters

Foreign

Session

Editing sessions

SESSION-POINT

Editing foreign sessions

Editing connections

Outconverter

Foreignsession

Address

Inconverter

WinConfig menu bar

File menu

Terminates WinConfig 122

Repository

System menu

Unix

Startvalue

Foreign-TA-App-Numbers

Again

MaxState

127

Startrm

Start

Dialog window Rmxa system

Rmxa

Cyclicorder

Cyclictime

Cycle

Dialog window Netaccess system

Netaccess

High , Medium , LOW

Priority

At least one parameter value not equal to

Dialog window SCHEDULE-System

Modified entries for Schedule statement are discarded again

Dialog window IMPORT-System

137

Direct Indirect

Area

Static Pool

139

Global Group

Mpool

141

Gina V4.0 System Administrator Guide September

Modified host name are discarded again

Hosts menu

145

TA-Apps menu

147

Dialog window Bcamappl

Foreign-Apps menu

Non-TA-Apps menu

Links menu

Multi Link

Deletes the values entered by the user

Dialog window Move Param

Moves menu

Physical Position Mouse action Effect Mouse key Mouse cursor

Mouse key assignments and mouse actions

Or foreign application will be gen Non-TA or foreign

Configuring T-ORB for BEA T Uxedo

System-wide settings

157

Cmapplication

Cmapplications

Cmprefix

Example

See Tmqforward Tuxedo System/T Message Forwarding Server

Openinfo

163

Usecmapplications

ReturnCONFIGERROR

Flag Token Debug Token Cmprefix Statement

System System Sbopen Debug Sbclose

Cmapplications Sbopen Number Sbclose

169

Openinfo Sbopen Letter Comma Letter Comma

Host Sbopen Letter Comma Backup Sbclose

Openinfo Sbopen Letter Comma Letter Sbclose

Openinfo Sbopen Letter Comma Application Sbclose

171

172

Application Sbopen Number Comma Letter Sbclose

Taapplication Sbopen Letter Comma Number Comma Sbclose

Revision generation

Druck vom 24 .2001 1701.00 torbkontux

176

Call and options

Cmd

Userfriendlyname.evf

Readme

Crtlogs.sh

Ubbconfig

Crbincf.sh

Crdevqu.sh

Generation without the -soption

Crdevqu.cmd

Crbincf.cmd

Crtlogs.cmd

183

BEA Tuxedo domains

Startvlaue

Domain

Export

Domain Sbopen Letter Sbclose

System Bbopen

UFN = Letter

Example of a configuration file with domains

189

Generated files

Dmconfig

Call and options

Special points

BEA Tuxedo domains 192

Communication structure of a server application

Communication administration

Communication structure of a client application

Data backup

DB administration

Security management

Logging database errors

Event Handler

Starting and stopping Gina applications

Transaction-monitored applications

Non-transaction-monitored applications

Dynamic Connection Handler

Dynamic T-ORB/clients

Event Handler and Dynamic Connection Handler under WindowsNT

Cyclical timer

Administering Gina applications

TP monitor

Time intervals for the monitoring of alarms

Monitoring alarms

Number of cyclical tasks

Cyclical tasks

Administering Gina applications 202

Application

Action point

Agent

Annotation

Client stub

Callback

Class method

Client

End of transaction

Data link point

Data reference

Distributed transaction

Global transaction

General reference

Global interface

Global reference

Join

Navigating access

Persistency Service

Job receiver

Reference

Persistent

Polymorphy

Proxy

Restart point

Remote reference

Request

Resource manager

Skeleton

Service

Shadowed attribute

Signature

Transaction manager

Time request

Transaction

Transaction-monitored request/call

Value-based access

Two-phase commit

XA protocol

Abbreviations

NEL

LU6.x

NLS

Open

WAN

Related publications

Gina V4.0 System Administrator Guide September

219

Gina V4.0 System Administrator Guide September

221

Related publications 222

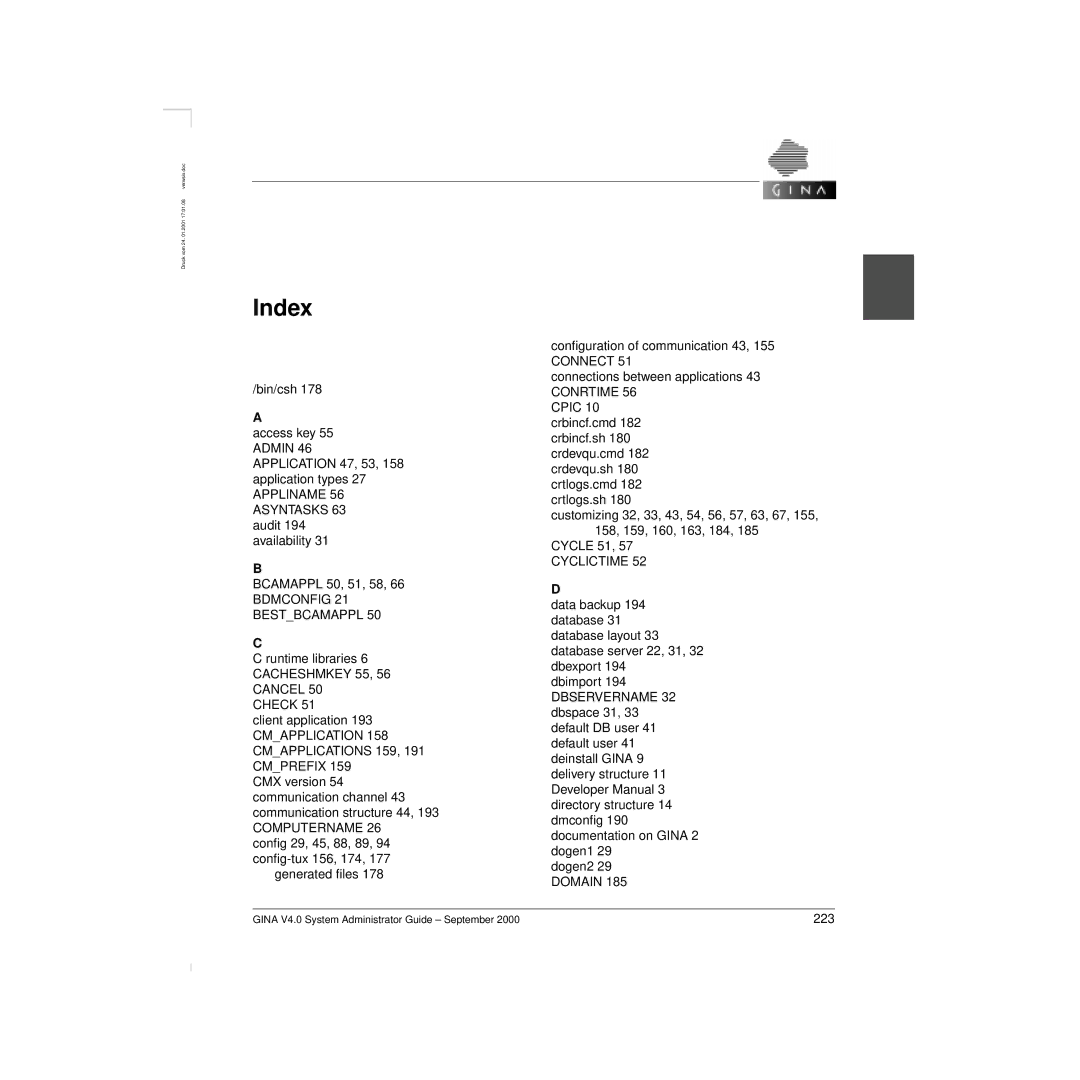

Index

Dynamicconnect

OQL

Name

Viewiteratorp

Fax 089 636-48

Comments

Page

Comments

Page