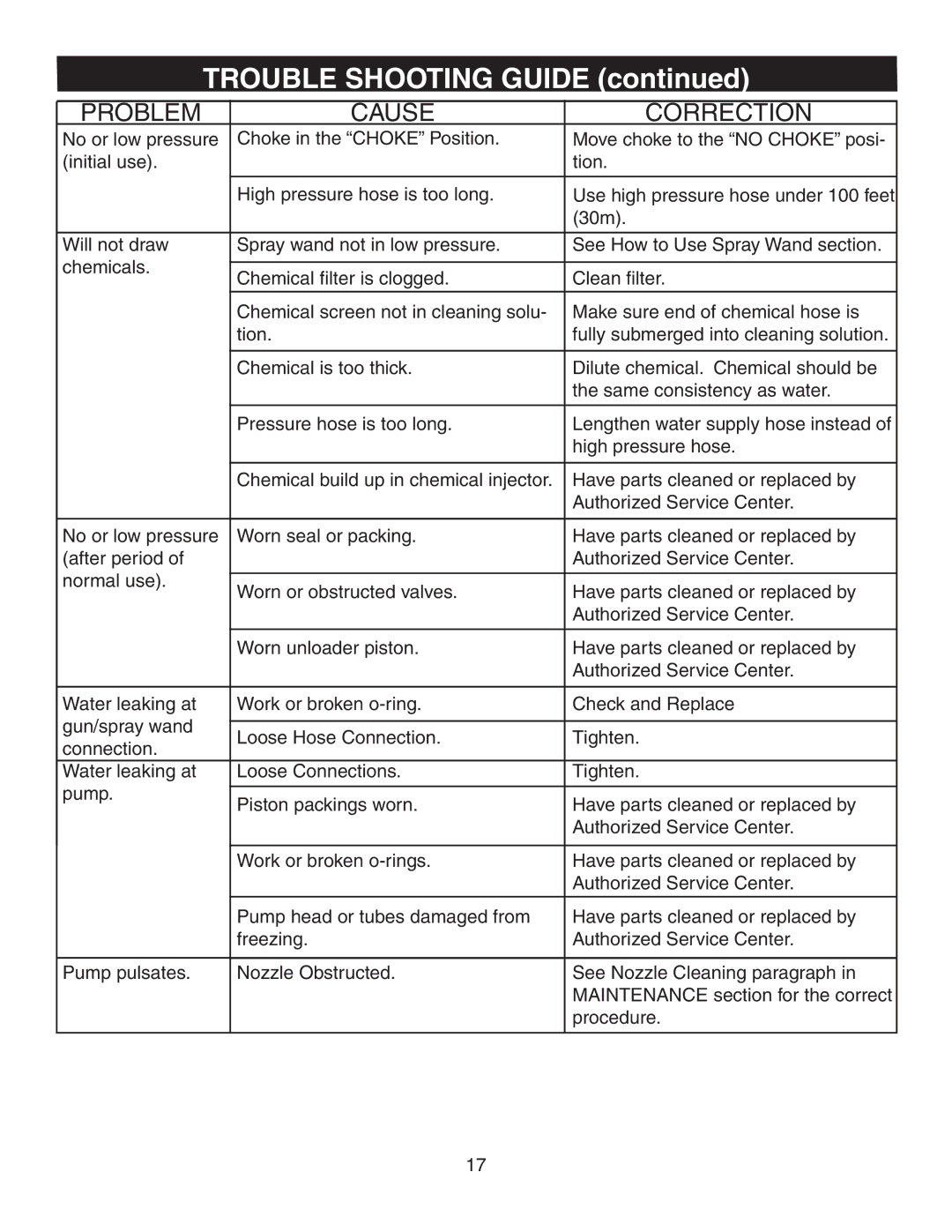

TROUBLE SHOOTING GUIDE (continued)

PROBLEM | CAUSE | CORRECTION | |

No or low pressure | Choke in the “CHOKE” Position. | Move choke to the “NO CHOKE” posi- | |

(initial use). |

| tion. | |

|

|

| |

| High pressure hose is too long. | Use high pressure hose under 100 feet | |

|

| (30m). | |

|

|

| |

Will not draw | Spray wand not in low pressure. | See How to Use Spray Wand section. | |

chemicals. |

|

| |

Chemical fi lter is clogged. | Clean fi lter. | ||

| |||

|

|

| |

| Chemical screen not in cleaning solu- | Make sure end of chemical hose is | |

| tion. | fully submerged into cleaning solution. | |

|

|

| |

| Chemical is too thick. | Dilute chemical. Chemical should be | |

|

| the same consistency as water. | |

|

|

| |

| Pressure hose is too long. | Lengthen water supply hose instead of | |

|

| high pressure hose. | |

|

|

| |

| Chemical build up in chemical injector. | Have parts cleaned or replaced by | |

|

| Authorized Service Center. | |

|

|

| |

No or low pressure | Worn seal or packing. | Have parts cleaned or replaced by | |

(after period of |

| Authorized Service Center. | |

normal use). |

|

| |

Worn or obstructed valves. | Have parts cleaned or replaced by | ||

| |||

|

| Authorized Service Center. | |

|

|

| |

| Worn unloader piston. | Have parts cleaned or replaced by | |

|

| Authorized Service Center. | |

|

|

| |

Water leaking at | Work or broken | Check and Replace | |

gun/spray wand |

|

| |

Loose Hose Connection. | Tighten. | ||

connection. | |||

|

| ||

Water leaking at | Loose Connections. | Tighten. | |

pump. |

|

| |

Piston packings worn. | Have parts cleaned or replaced by | ||

| |||

|

| Authorized Service Center. | |

|

|

| |

| Work or broken | Have parts cleaned or replaced by | |

|

| Authorized Service Center. | |

|

|

| |

| Pump head or tubes damaged from | Have parts cleaned or replaced by | |

| freezing. | Authorized Service Center. | |

|

|

| |

Pump pulsates. | Nozzle Obstructed. | See Nozzle Cleaning paragraph in | |

|

| MAINTENANCE section for the correct | |

|

| procedure. | |

|

|

|

17