|

| Operation (continued) |

| |

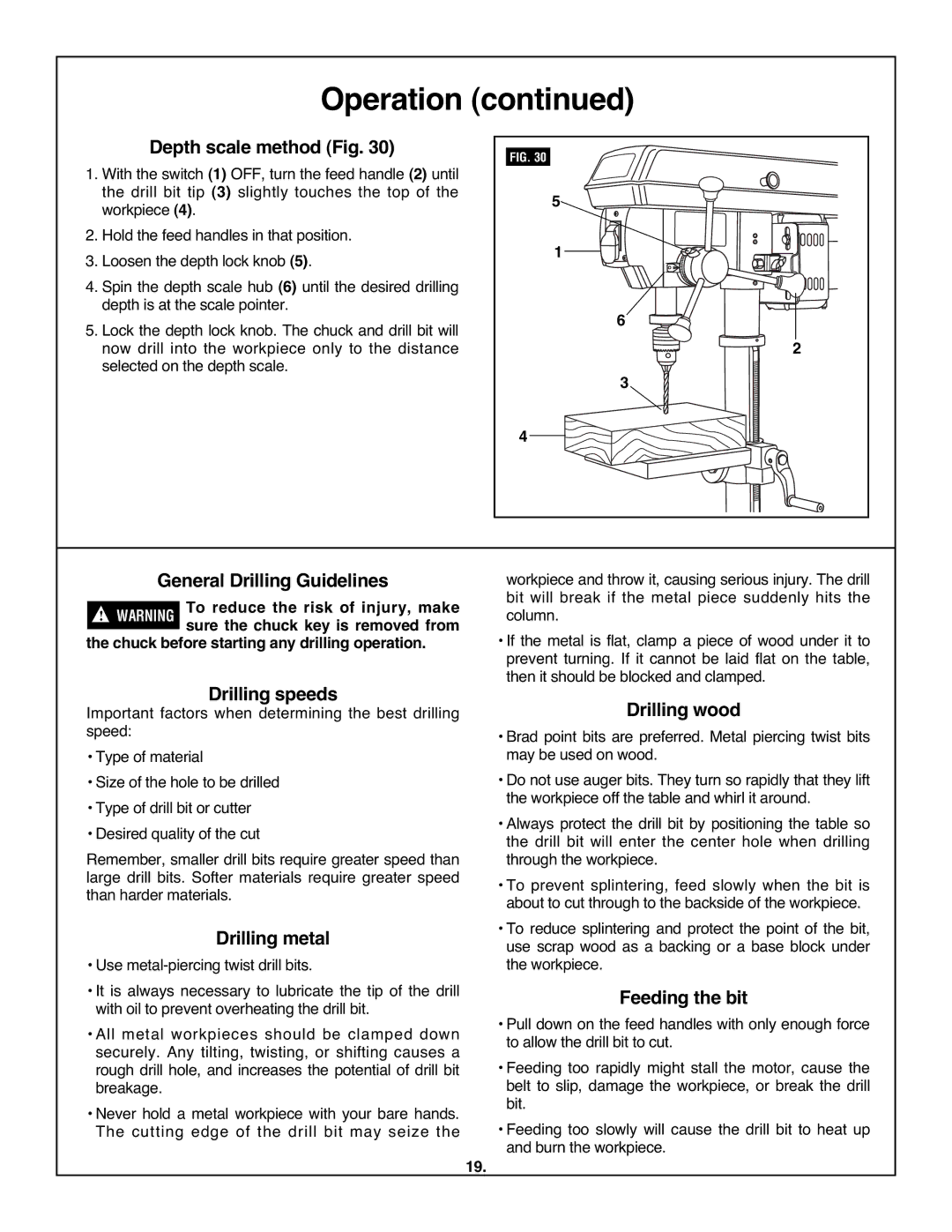

1. | Depth scale method (Fig. 30) | FIG. 30 |

| |

With the switch | (1) OFF, turn the feed handle (2) until |

|

| |

| the drill bit tip | (3) slightly touches the top of the | 5 |

|

2. | workpiece (4). |

|

| |

Hold the feed handles in that position. | 1 |

| ||

3. | Loosen the depth lock knob (5). |

| ||

4. | Spin the depth scale hub (6) until the desired drilling |

|

| |

5. | depth is at the scale pointer. | 6 |

| |

Lock the depth lock knob. The chuck and drill bit will | 2 | |||

| now drill into the workpiece only to the distance |

| ||

| selected on the depth scale. | 3 |

| |

|

|

|

| |

General Drilling Guidelines

!To reduce the risk of injury, make sure the chuck key is removed from

the chuckWARNINGbefore starting any drilling operation.

Drilling speeds

Important factors when determining the best drilling speed:

• Type of material

• Size of the hole to be drilled

• Type of drill bit or cutter

• Desired quality of the cut

Remember, smaller drill bits require greater speed than large drill bits. Softer materials require greater speed than harder materials.

Drilling metal

• Use

• It is always necessary to lubricate the tip of the drill with oil to prevent overheating the drill bit.

• All metal workpieces should be clamped down securely. Any tilting, twisting, or shifting causes a rough drill hole, and increases the potential of drill bit breakage.

• Never hold a metal workpiece with your bare hands. The cutting edge of the drill bit may seize the 19.