Adjustments

Blade 45° To The Table

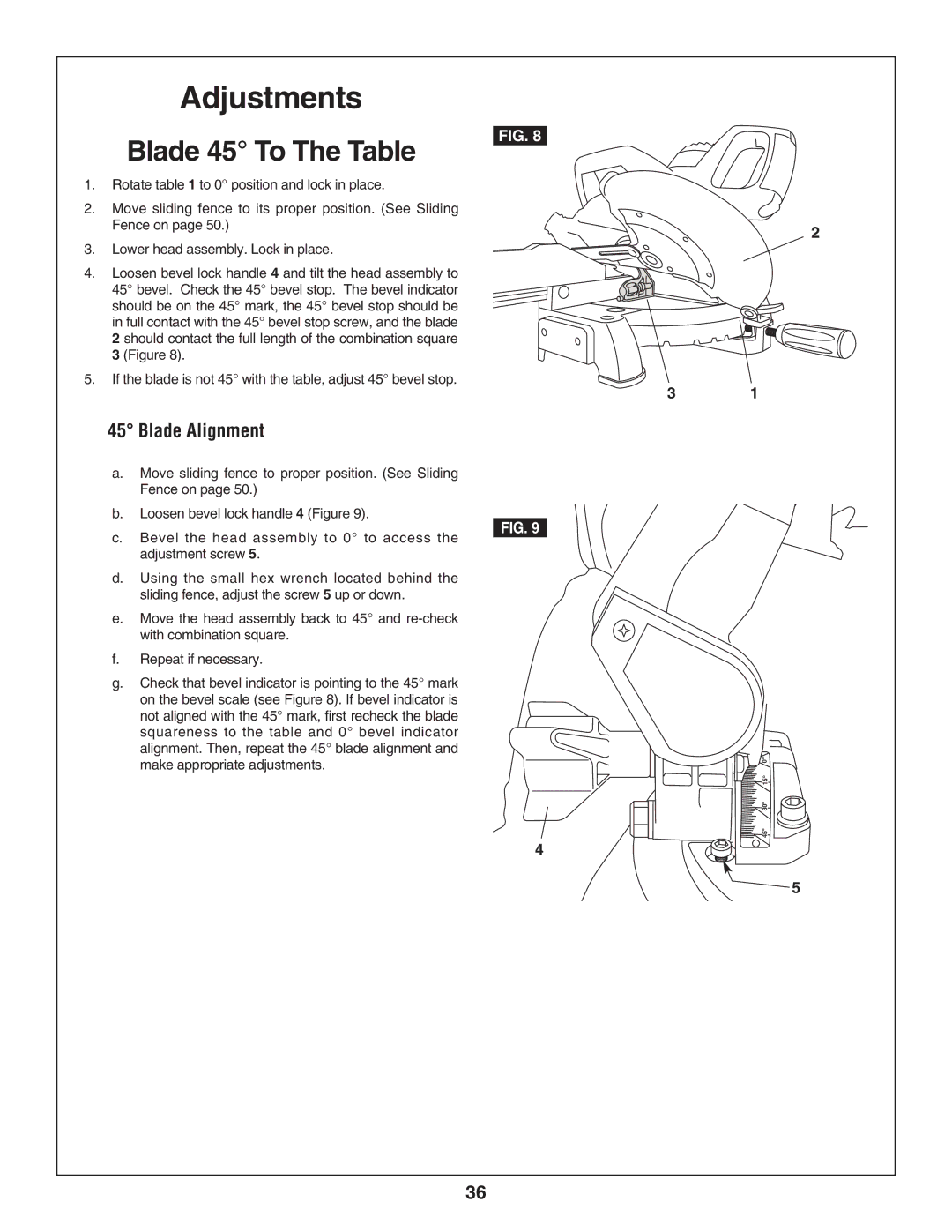

FIG. 8

1.Rotate table 1 to 0° position and lock in place.

2.Move sliding fence to its proper position. (See Sliding

Fence on page 50.)

3. Lower head assembly. Lock in place.

4. Loosen bevel lock handle 4 and tilt the head assembly to 45° bevel. Check the 45° bevel stop. The bevel indicator should be on the 45° mark, the 45° bevel stop should be in full contact with the 45° bevel stop screw, and the blade 2 should contact the full length of the combination square 3 (Figure 8).

5. If the blade is not 45° with the table, adjust 45° bevel stop.

2

3 1

45° Blade Alignment

a.Move sliding fence to proper position. (See Sliding Fence on page 50.)

b.Loosen bevel lock handle 4 (Figure 9).

c. | Bevel the head assembly to 0° to access the | FIG. 9 |

| ||

| adjustment screw 5. |

|

d. | Using the small hex wrench located behind the |

|

| sliding fence, adjust the screw 5 up or down. |

|

e. | Move the head assembly back to 45° and |

|

| with combination square. |

|

f. | Repeat if necessary. |

|

g. | Check that bevel indicator is pointing to the 45° mark |

|

| on the bevel scale (see Figure 8). If bevel indicator is |

|

| not aligned with the 45° mark, first recheck the blade |

|

| squareness to the table and 0° bevel indicator |

|

| alignment. Then, repeat the 45° blade alignment and | º |

| make appropriate adjustments. | |

| 0 | |

|

| |

|

| º |

|

| 5 |

|

| 1 |

|

| º |

|

| 0 |

|

| 3 |

|

| º |

|

| 5 |

|

| 4 |

4

![]() 5

5

36