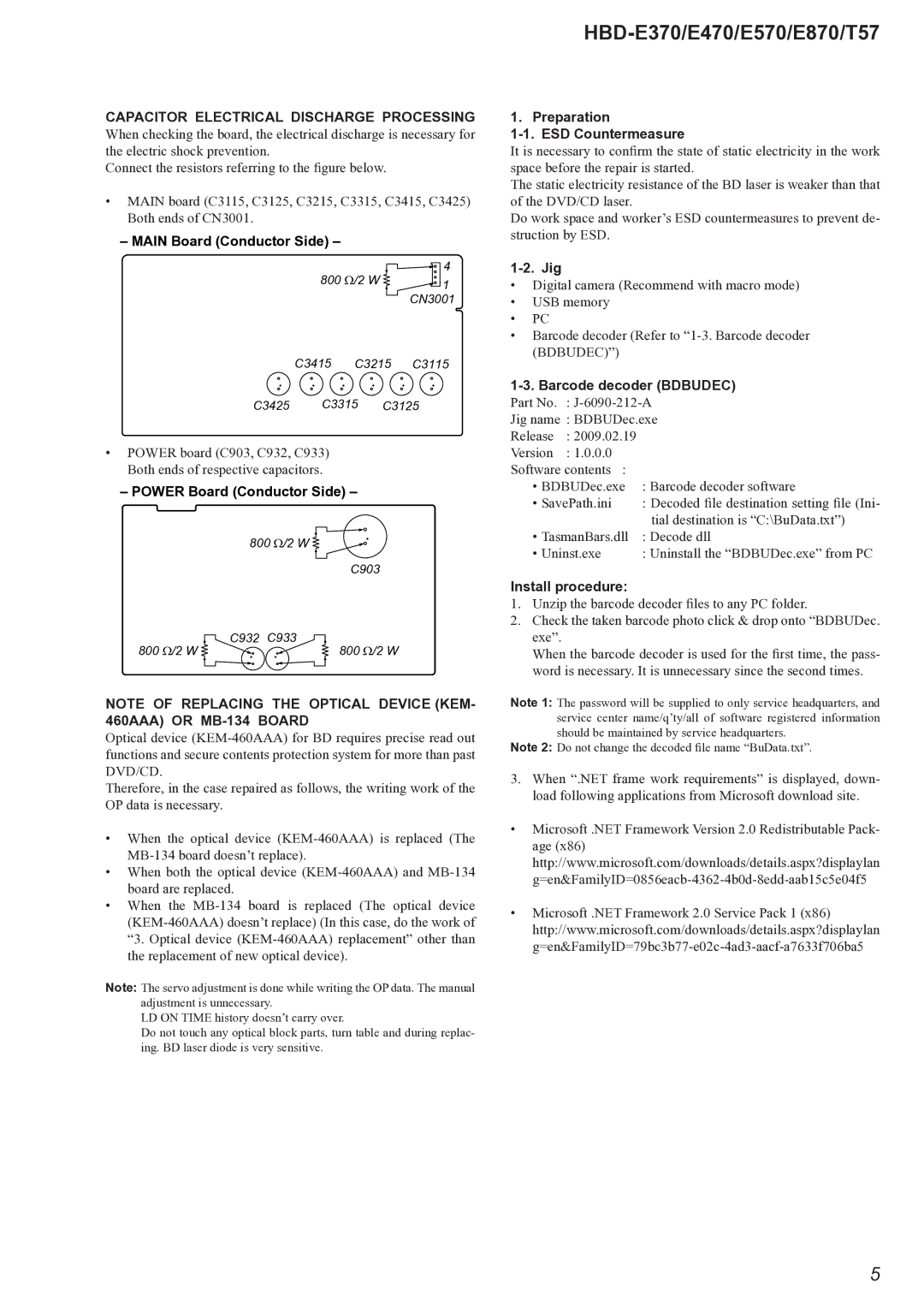

CAPACITOR ELECTRICAL DISCHARGE PROCESSING When checking the board, the electrical discharge is necessary for the electric shock prevention.

Connect the resistors referring to the figure below.

•MAIN board (C3115, C3125, C3215, C3315, C3415, C3425) Both ends of CN3001.

–MAIN Board (Conductor Side) –

800 :/2 W | 4 | |

1 | ||

| ||

| CN3001 |

C3415 C3215 C3115

C3425 C3315 C3125

•POWER board (C903, C932, C933) Both ends of respective capacitors.

–POWER Board (Conductor Side) –

800 :/2 W

C903

C932 C933

800 :/2 W | 800 :/2 W |

NOTE OF REPLACING THE OPTICAL DEVICE (KEM- 460AAA) OR

Optical device

Therefore, in the case repaired as follows, the writing work of the OP data is necessary.

•When the optical device

•When both the optical device

•When the

Note: The servo adjustment is done while writing the OP data. The manual adjustment is unnecessary.

LD ON TIME history doesn’t carry over.

Do not touch any optical block parts, turn table and during replac- ing. BD laser diode is very sensitive.

HBD-E370/E470/E570/E870/T57

1. Preparation

1-1. ESD Countermeasure

It is necessary to confirm the state of static electricity in the work space before the repair is started.

The static electricity resistance of the BD laser is weaker than that of the DVD/CD laser.

Do work space and worker’s ESD countermeasures to prevent de- struction by ESD.

1-2. Jig

•Digital camera (Recommend with macro mode)

•USB memory

•PC

•Barcode decoder (Refer to

1-3. Barcode decoder (BDBUDEC) Part No. : J-6090-212-A

Jig name : BDBUDec.exe

Release | : 2009.02.19 |

|

Version | : 1.0.0.0 |

|

Software contents : |

| |

• BDBUDec.exe | : Barcode decoder software | |

• SavePath.ini | : Decoded file destination setting file (Ini- | |

|

| tial destination is “C:\BuData.txt”) |

• TasmanBars.dll | : Decode dll | |

• Uninst.exe | : Uninstall the “BDBUDec.exe” from PC | |

Install procedure:

1.Unzip the barcode decoder files to any PC folder.

2.Check the taken barcode photo click & drop onto “BDBUDec. exe”.

When the barcode decoder is used for the first time, the pass- word is necessary. It is unnecessary since the second times.

Note 1: The password will be supplied to only service headquarters, and service center name/q’ty/all of software registered information should be maintained by service headquarters.

Note 2: Do not change the decoded file name “BuData.txt”.

3.When “.NET frame work requirements” is displayed, down- load following applications from Microsoft download site.

•Microsoft .NET Framework Version 2.0 Redistributable Pack- age (x86) http://www.microsoft.com/downloads/details.aspx?displaylan

•Microsoft .NET Framework 2.0 Service Pack 1 (x86) http://www.microsoft.com/downloads/details.aspx?displaylan

5