5-2. PRECAUTIONS FOR CHECKING LASER DIODE EMISSINON

To check the emission of the laser diode during adjustments, never view directly from the top as this may lose your

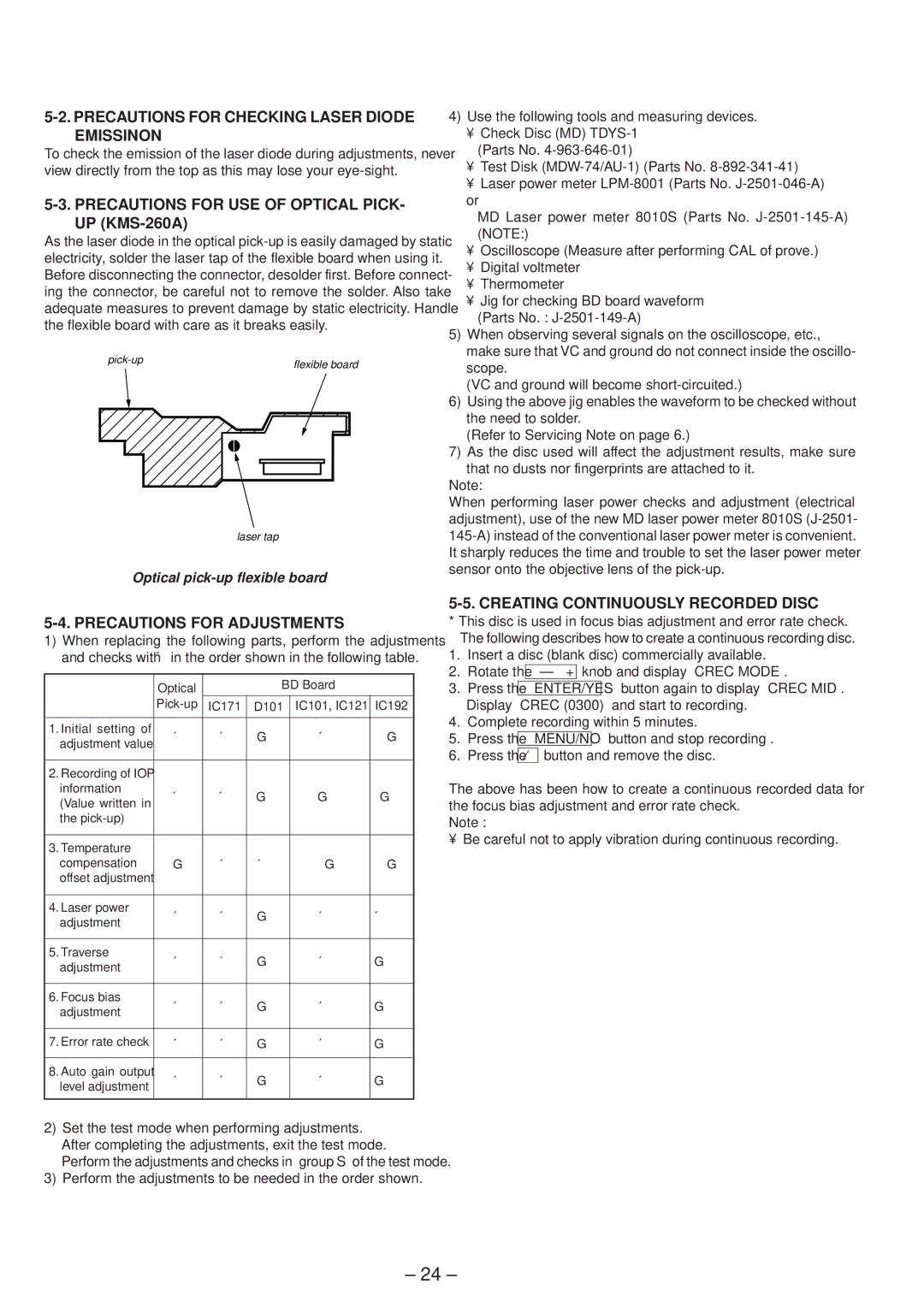

5-3. PRECAUTIONS FOR USE OF OPTICAL PICK- UP (KMS-260A)

As the laser diode in the optical

flexible board | |

|

laser tap

Optical

5-4. PRECAUTIONS FOR ADJUSTMENTS

1)When replacing the following parts, perform the adjustments and checks with ¬ in the order shown in the following table.

| Optical |

|

| BD Board |

| |

|

| IC171 | D101 |

| IC101, IC121 | IC192 |

|

|

|

|

|

|

|

1. Initial setting of | ¬ | ¬ | G |

| ¬ | G |

adjustment value |

| |||||

|

|

|

|

|

|

|

2. Recording of IOP |

|

|

|

|

|

|

information | ¬ | ¬ | G |

| G | G |

(Value written in |

| |||||

the |

|

|

|

|

|

|

|

|

|

|

|

|

|

3. Temperature |

|

|

|

|

|

|

compensation | G | ¬ | ¬ |

| G | G |

offset adjustment |

|

|

|

|

|

|

|

|

|

|

|

|

|

4. Laser power | ¬ | ¬ | G |

| ¬ | ¬ |

adjustment |

| |||||

|

|

|

|

|

| |

|

|

|

|

|

|

|

5. Traverse | ¬ | ¬ | G |

| ¬ | G |

adjustment |

| |||||

|

|

|

|

|

| |

|

|

|

|

|

|

|

6. Focus bias | ¬ | ¬ | G |

| ¬ | G |

adjustment |

| |||||

|

|

|

|

|

| |

|

|

|

|

|

|

|

7. Error rate check | ¬ | ¬ | G |

| ¬ | G |

|

|

|

|

|

|

|

8. Auto gain output | ¬ | ¬ | G |

| ¬ | G |

level adjustment |

|

|

|

|

|

|

2)Set the test mode when performing adjustments. After completing the adjustments, exit the test mode.

Perform the adjustments and checks in “group S” of the test mode.

3)Perform the adjustments to be needed in the order shown.

4) Use the following tools and measuring devices.

•Check Disc (MD)

•Test Disk

•Laser power meter

or

MD Laser power meter 8010S (Parts No.

•Oscilloscope (Measure after performing CAL of prove.)

•Digital voltmeter

•Thermometer

•Jig for checking BD board waveform

(Parts No. :

5)When observing several signals on the oscilloscope, etc., make sure that VC and ground do not connect inside the oscillo- scope.

(VC and ground will become

6)Using the above jig enables the waveform to be checked without the need to solder.

(Refer to Servicing Note on page 6.)

7)As the disc used will affect the adjustment results, make sure

that no dusts nor fingerprints are attached to it.

Note:

When performing laser power checks and adjustment (electrical adjustment), use of the new MD laser power meter 8010S

5-5. CREATING CONTINUOUSLY RECORDED DISC

* This disc is used in focus bias adjustment and error rate check. The following describes how to create a continuous recording disc.

1.Insert a disc (blank disc) commercially available.

2.Rotate the

3.Press the ENTER/YES button again to display “CREC MID”. Display “CREC (0300)” and start to recording.

4.Complete recording within 5 minutes.

5.Press the MENU/NO button and stop recording .

6.Press the § button and remove the disc.

The above has been how to create a continuous recorded data for the focus bias adjustment and error rate check.

Note :

• Be careful not to apply vibration during continuous recording.

– 24 –