7.Then, rotate the

8.Press the ENTER/YES button once and display “LD 0.9 mW $

![]()

![]() ”. Check that the reading of the laser power meter become 0.85 to 0.91 mW.

”. Check that the reading of the laser power meter become 0.85 to 0.91 mW.

9.Press the ENTER/YES button once more and display “LD 7.0 mW $ ![]()

![]() ”. Check that the reading the laser power meter and digital volt meter satisfy the specified value.

”. Check that the reading the laser power meter and digital volt meter satisfy the specified value.

Note down the digital voltmeter reading value.

Specified Value :

Laser power meter reading : 7.0 ± 0.1 mW

Digital voltmeter reading : Optical

(Optical pick-up label)

KMS260A | (For details of the method for checking | |

27X40 | this value, refer to | |

Displaying IOP Information”.) | ||

B0825 | ||

| ||

|

| |

N |

|

Iop = 82.5 mA in this case

Iop (mA) = Digital voltmeter reading (mV)/1 (Ω)

10.Press the MENU/NO button and display “LDPWR CHECK” and stop the laser emission.

(The MENU/NO button is effective at all times to stop the laser emission.)

11.Rotate the

12.Press the ENTER/YES button. When the display becomes Ref=@@@.@ (@ is an arbitrary number), press the ENTER/ YES button to display “Measu=@@@.@” (@ is an arbitrary number).

13.The numbers which can be changed will blink. Input the Iop

value noted down at step 9.

To select the number : Rotate the

To select the digit : Press the CD SYNC/MD WM SYNC but- ton.

14.When the ENTER/YES button is pressed, “Complete!” will be displayed momentarily. The value will be recorded in the

Note 1: After step 4, each time the ENTER/YES button is pressed, the display will be switched between “LD 0.7 mW $ ![]()

![]() ”,

”,

“LD 6.2 mW $ ![]()

![]()

![]()

![]() ”, and “LD Wp

”, and “LD Wp ![]()

![]()

![]()

![]() $

$ ![]()

![]()

![]()

![]() ”. Nothing needs to be performed here.

”. Nothing needs to be performed here.

5-11. TRAVERSE ADJUSTMENT

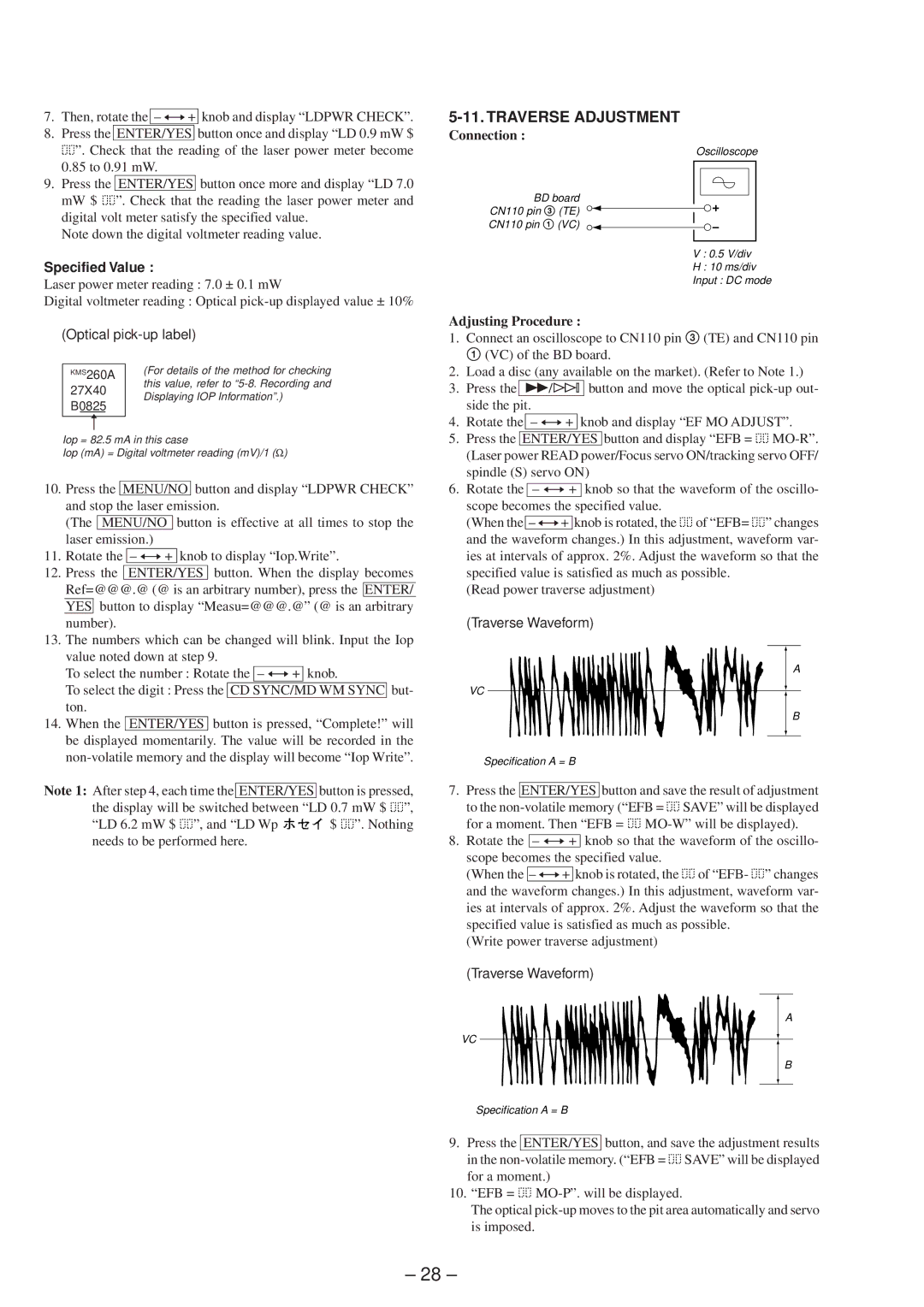

Connection :

Oscilloscope

BD board

CN110 pin 3 (TE)

CN110 pin 1 (VC)

V : 0.5 V/div

H : 10 ms/div

Input : DC mode

Adjusting Procedure :

1.Connect an oscilloscope to CN110 pin 3 (TE) and CN110 pin 1 (VC) of the BD board.

2.Load a disc (any available on the market). (Refer to Note 1.)

3.Press the )/± button and move the optical

4.Rotate the

5.Press the ENTER/YES button and display “EFB = ![]()

![]()

6.Rotate the

scope becomes the specified value.

(When the ![]()

![]() of “EFB=

of “EFB= ![]()

![]() ” changes and the waveform changes.) In this adjustment, waveform var- ies at intervals of approx. 2%. Adjust the waveform so that the specified value is satisfied as much as possible.

” changes and the waveform changes.) In this adjustment, waveform var- ies at intervals of approx. 2%. Adjust the waveform so that the specified value is satisfied as much as possible.

(Read power traverse adjustment)

(Traverse Waveform)

A

VC

B

Specification A = B

7.Press the ENTER/YES button and save the result of adjustment to the ![]()

![]() SAVE” will be displayed

SAVE” will be displayed

for a moment. Then “EFB = ![]()

![]()

8.Rotate the

scope becomes the specified value.

(When the ![]()

![]() of “EFB-

of “EFB- ![]()

![]() ” changes and the waveform changes.) In this adjustment, waveform var- ies at intervals of approx. 2%. Adjust the waveform so that the specified value is satisfied as much as possible.

” changes and the waveform changes.) In this adjustment, waveform var- ies at intervals of approx. 2%. Adjust the waveform so that the specified value is satisfied as much as possible.

(Write power traverse adjustment)

(Traverse Waveform)

A

VC

B

Specification A = B

9.Press the ENTER/YES button, and save the adjustment results in the ![]()

![]() SAVE” will be displayed for a moment.)

SAVE” will be displayed for a moment.)

10.“EFB = ![]()

![]()

The optical

– 28 –