Model SB1023 | M A I N T E N A N C E | For Machines Mfg. Since 8/09 |

Maintenance

Maintenance Schedule

! | Always disconnect |

| machine from power before |

| performing maintenance or |

| serious personal injury may |

| result. |

To keep this machine in the best operating condition, make sure to complete the follow- ing maintenance items within the minimum intervals listed below.

Daily:

•Check for and correct loose mounting bolts.

•Check for and correct damaged or cracked grinding wheel.

•Check for and correct worn or damaged wires.

•Clean and protect table.

•Vacuum metal shavings from machine.

•Correct any other unsafe condition.

Bi-weekly

•Remove the table, clean and relubricate the ways, ball bearings, and rack and pinion.

•Lubricate the column grease fitting with two pumps of grease.

•Lubricate the table cross way grease fitting with two pumps of grease.

•Clean and grease all three leadscrews.

Lubrication

If this machine is used in a heavy industrial setting, or in a dirty or damp environment, increase the lubrication intervals.

To lubricate your machine:

1.DISCONNECT MACHINE FROM POWER!

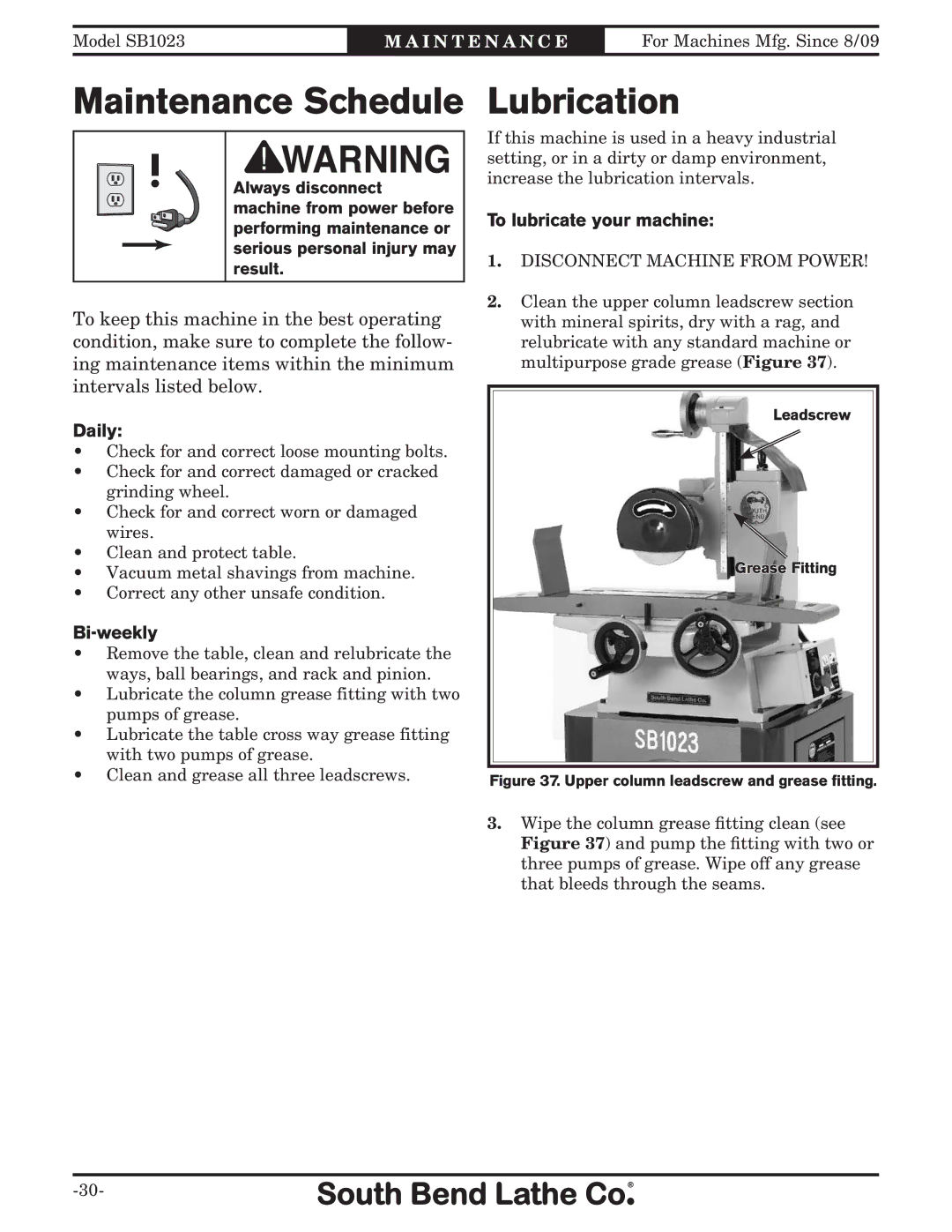

2.Clean the upper column leadscrew section with mineral spirits, dry with a rag, and relubricate with any standard machine or multipurpose grade grease (Figure 37).

Leadscrew

Grease Fitting

Figure 37. Upper column leadscrew and grease fitting.

3.Wipe the column grease fitting clean (see Figure 37) and pump the fitting with two or three pumps of grease. Wipe off any grease that bleeds through the seams.