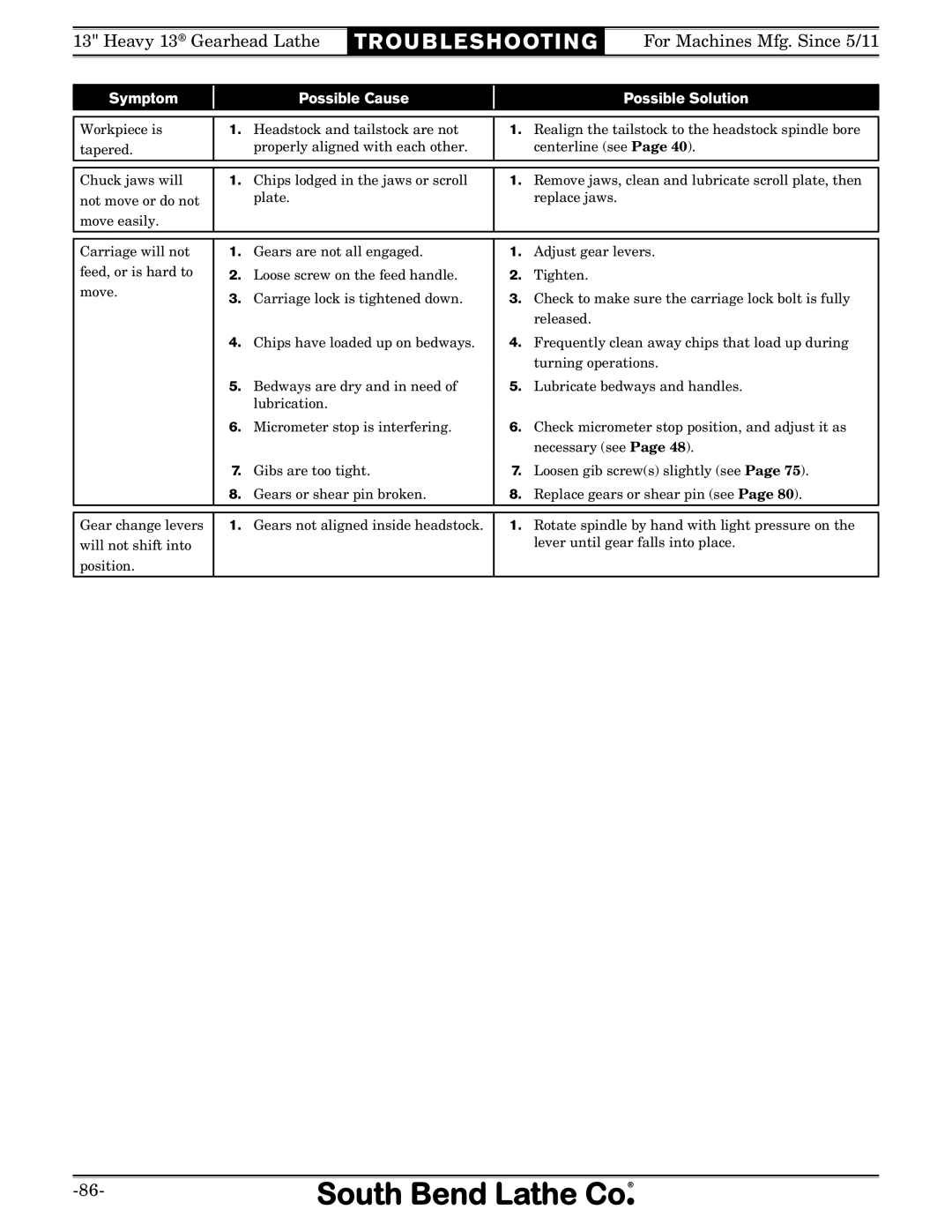

13" Heavy 13® Gearhead Lathe TR O U B L E S H O OTI N G For Machines Mfg. Since 5/11

Symptom

Possible Cause

Possible Solution

Workpiece is | 1. | Headstock and tailstock are not | 1. | Realign the tailstock to the headstock spindle bore |

tapered. |

| properly aligned with each other. |

| centerline (see Page 40). |

|

|

|

|

|

|

|

|

|

|

Chuck jaws will | 1. | Chips lodged in the jaws or scroll | 1. | Remove jaws, clean and lubricate scroll plate, then |

not move or do not |

| plate. |

| replace jaws. |

move easily. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Carriage will not | 1. | Gears are not all engaged. | 1. | Adjust gear levers. |

feed, or is hard to | 2. | Loose screw on the feed handle. | 2. | Tighten. |

move. | 3. | Carriage lock is tightened down. | 3. | Check to make sure the carriage lock bolt is fully |

| ||||

|

|

|

| released. |

4.Chips have loaded up on bedways. 4. Frequently clean away chips that load up during turning operations.

5. Bedways are dry and in need of | 5. Lubricate bedways and handles. |

lubrication. |

|

6.Micrometer stop is interfering. 6. Check micrometer stop position, and adjust it as necessary (see Page 48).

7. Gibs are too tight. | 7. Loosen gib screw(s) slightly (see Page 75). |

8.Gears or shear pin broken.8. Replace gears or shear pin (see Page 80).

Gear change levers | 1. Gears not aligned inside headstock. | 1. Rotate spindle by hand with light pressure on the |

will not shift into |

| lever until gear falls into place. |

position. |

|

|