TROUbLESHOOTING | ||

|

|

|

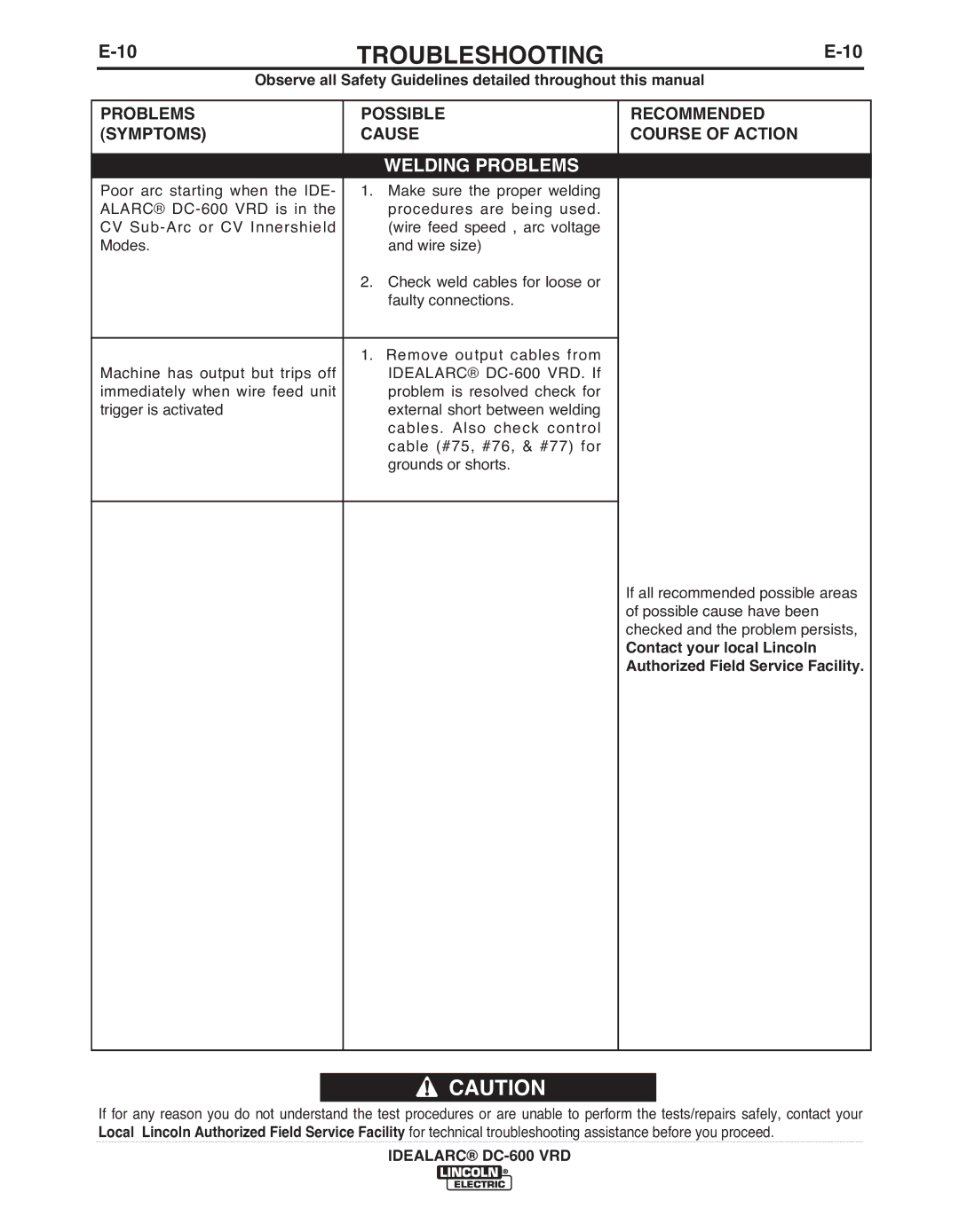

| Observe all Safety Guidelines detailed throughout this manual |

|

PRObLEMS | POSSIbLE |

(SYMPTOMS) | CAUSE |

|

|

| WELDING PRObLEMS |

| Poor arc starting when the IDE- | 1. | Make sure the proper welding |

| |||

| ALARC® |

| procedures are being used. |

| CV |

| (wire feed speed , arc voltage |

| Modes. |

| and wire size) |

|

| 2. | Check weld cables for loose or |

|

|

| faulty connections. |

|

|

|

|

|

| 1. | Remove output cables from |

| Machine has output but trips off |

| IDEALARC® |

| immediately when wire feed unit |

| problem is resolved check for |

| trigger is activated |

| external short between welding |

|

|

| cables. Also check control |

|

|

| cable (#75, #76, & #77) for |

|

|

| grounds or shorts. |

|

|

|

|

|

|

|

|

RECOMMENDED

COURSE OF ACTION

If all recommended possible areas of possible cause have been checked and the problem persists,

Contact your local Lincoln Authorized Field Service Facility.

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

IDEALARC®