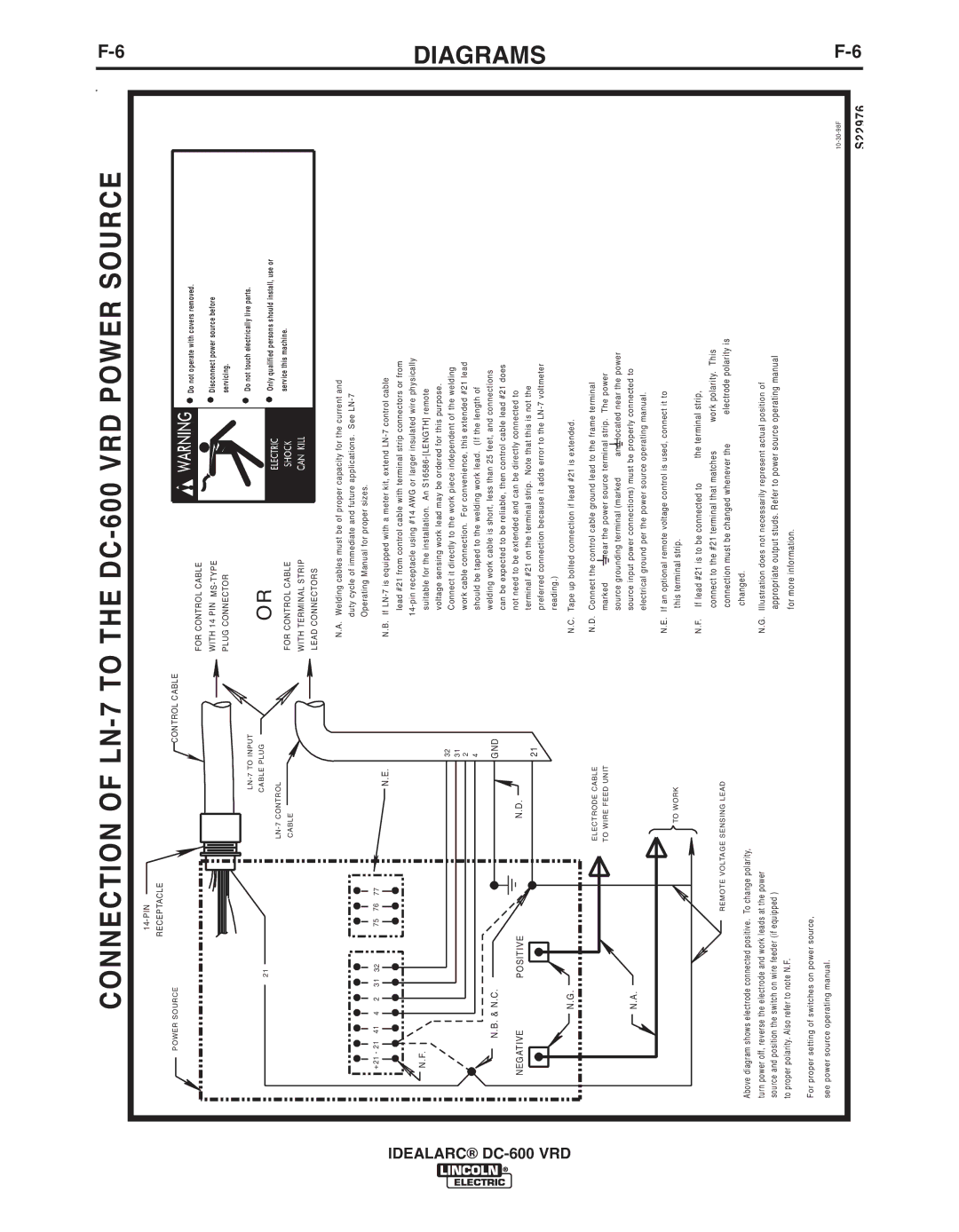

CONNECTION OF LN-7 TO THE DC-600 VRD POWER SOURCE

| |

| RECEPTACLE |

POWER SOURCE | CONTROL CABLE |

| |

21 | CABLE PLUG |

|

CABLE

FOR CONTROL CABLE | Do not operate with covers removed. |

| |

WITH 14 PIN | Disconnect power source before |

PLUG CONNECTOR | servicing. |

OR | Do not touch electrically live parts. |

Only qualified persons should install, use or | |

FOR CONTROL CABLE | service this machine. |

WITH TERMINAL STRIP |

|

LEAD CONNECTORS |

|

N.A. Welding cables must be of proper capacity for the current and duty cycle of immediate and future applications. See

![]() IDEALARC®

IDEALARC®

+ 21 - 21 | 41 | 4 | 2 | 31 | 32 | 75 | 76 | 77 | N.E. | N.B. If | |||

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

| lead #21 from control cable with terminal strip connectors or from | ||

N.F. |

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

| suitable for the installation. An | |||

|

|

|

|

|

|

|

|

| 32 |

| voltage sensing work lead may be ordered for this purpose. | ||

|

|

|

|

|

|

|

|

|

| Connect it directly to the work piece independent of the welding | |||

|

|

|

|

|

|

|

|

| 31 |

| work cable connection. For convenience, this extended #21 lead | ||

|

|

|

|

|

|

|

|

| 2 |

| |||

|

|

|

|

|

|

|

|

| 4 |

| should be taped to the welding work lead. (If the length of | ||

| N.B. & N.C. |

|

|

|

|

| GND |

| welding work cable is short, less than 25 feet, and connections | ||||

|

|

|

|

|

|

| can be expected to be reliable, then control cable lead #21 does | ||||||

|

|

|

|

|

|

|

|

|

|

| |||

NEGATIVE |

|

|

| POSITIVE |

|

|

| N.D. |

| not need to be extended and can be directly connected to | |||

|

|

|

|

|

|

|

|

| 21 |

| terminal #21 on the terminal strip. Note that this is not the | ||

|

|

|

|

|

|

|

|

|

| preferred connection because it adds error to the | |||

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

| reading.) |

|

|

|

|

| N.G. |

|

|

|

|

|

| N.C. Tape up bolted connection if lead #21 is extended. | |||

|

|

|

|

|

|

|

|

| ELECTRODE CABLE | N.D. Connect the control cable ground lead to the frame terminal | |||

|

|

|

|

|

|

|

|

| TO WIRE FEED UNIT |

| marked | near the power source terminal strip. The power | |

|

|

|

|

|

|

|

|

|

|

| source grounding terminal (marked | and located near the power | |

|

|

| N.A. |

|

|

|

|

|

|

| source input power connections) must be properly connected to | ||

|

|

|

|

|

|

|

|

|

|

| electrical ground per the power source operating manual. | ||

|

|

|

|

|

|

|

|

|

| N.E. If an optional remote voltage control is used, connect it to | |||

|

|

|

|

|

|

|

|

| TO WORK |

| this terminal strip. |

| |

|

|

|

|

|

|

|

|

|

| N.F. | If lead #21 is to be connected to | the terminal strip, | |

DIAGRAMS

REMOTE VOLTAGE SENSING LEAD

Above diagram shows electrode connected positive. To change polarity,

turn power off, reverse the electrode and work leads at the power source and position the switch on wire feeder (if equipped )

to proper polarity. Also refer to note N.F.

For proper setting of switches on power source, see power source operating manual.

connect to the #21 terminal that matches | work polarity. This |

connection must be changed whenever the | electrode polarity is |

changed. |

|

N.G. Illustration does not necessarily represent actual position of

appropriate output studs. Refer to power source operating manual for more information.

F-

S22976

6