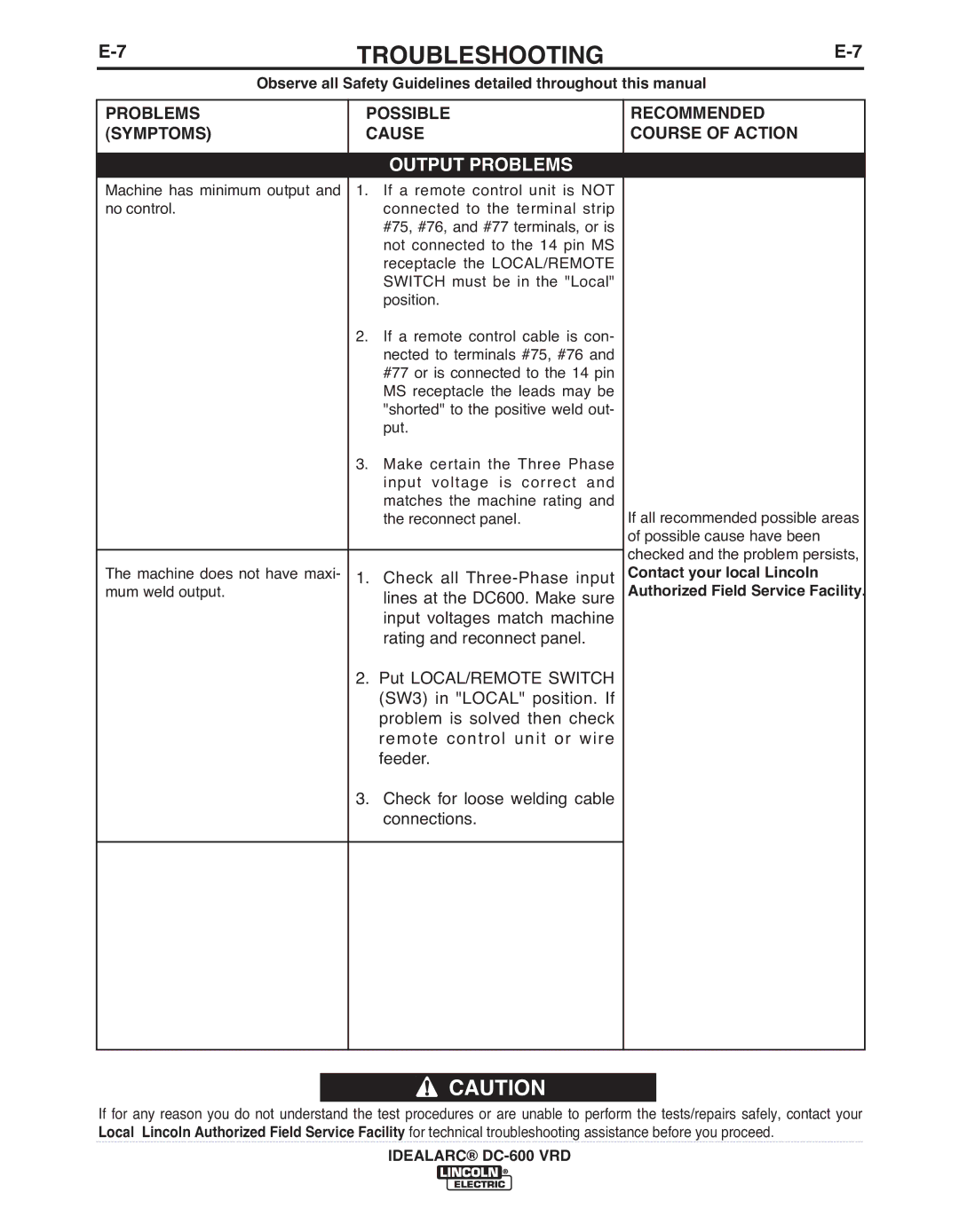

TROUbLESHOOTING | ||

|

|

|

| Observe all Safety Guidelines detailed throughout this manual |

|

PRObLEMS | POSSIbLE |

(SYMPTOMS) | CAUSE |

|

|

| OUTPUT PRObLEMS |

| Machine has minimum output and | 1. | If a remote control unit is NOT |

| |||

| no control. |

| connected to the terminal strip |

|

|

| #75, #76, and #77 terminals, or is |

|

|

| not connected to the 14 pin MS |

|

|

| receptacle the LOCAL/REMOTE |

|

|

| SWITCH must be in the "Local" |

|

|

| position. |

|

| 2. | If a remote control cable is con- |

|

|

| nected to terminals #75, #76 and |

|

|

| #77 or is connected to the 14 pin |

|

|

| MS receptacle the leads may be |

|

|

| "shorted" to the positive weld out- |

|

|

| put. |

|

| 3. | Make certain the Three Phase |

|

|

| input voltage is correct and |

|

|

| matches the machine rating and |

|

|

| the reconnect panel. |

|

|

|

|

| The machine does not have maxi- | 1. | Check all |

| mum weld output. |

| lines at the DC600. Make sure |

|

|

| |

|

|

| input voltages match machine |

|

|

| rating and reconnect panel. |

|

| 2. Put LOCAL/REMOTE SWITCH | |

|

|

| (SW3) in "LOCAL" position. If |

|

|

| problem is solved then check |

|

|

| remote control unit or wire |

|

|

| feeder. |

|

| 3. | Check for loose welding cable |

|

|

| connections. |

|

|

|

|

|

|

|

|

RECOMMENDED

COURSE OF ACTION

If all recommended possible areas of possible cause have been checked and the problem persists,

Contact your local Lincoln Authorized Field Service Facility.

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

IDEALARC®