SPECIFICATIONS | RADIANT STEAKHOUSE BROILER |

If a ventilation canopy is used, it is recommended that the canopy extend 6" (152 mm) past the broiler and that the bottom edge be located 6'6" (1980 mm) from the floor. Filters should be installed at an angle of 45° or more from the horizontal. This position prevents dripping grease, and facilitates collecting the

A strong exhaust fan tends to create a vacuum in the room and may interfere with burner performance or may extinguish pilot flames. Fresh air openings approximately equal to the fan area will relieve such a vacuum. The exhaust fan should be installed at least 2" (51 mm) above the vent opening on the top rear of the broiler.

If the broiler is connected directly to an outside flue, a CSA

In case of unsatisfactory performance by any gas appliance, check the appliance with the exhaust fan turned OFF. Do this only long enough to check whether doing so corrects any problems with equipment performance. Then turn the exhaust fan back on and let it run to remove any exhaust that may have accumulated during the test.

GAS SUPPLY

The broiler is

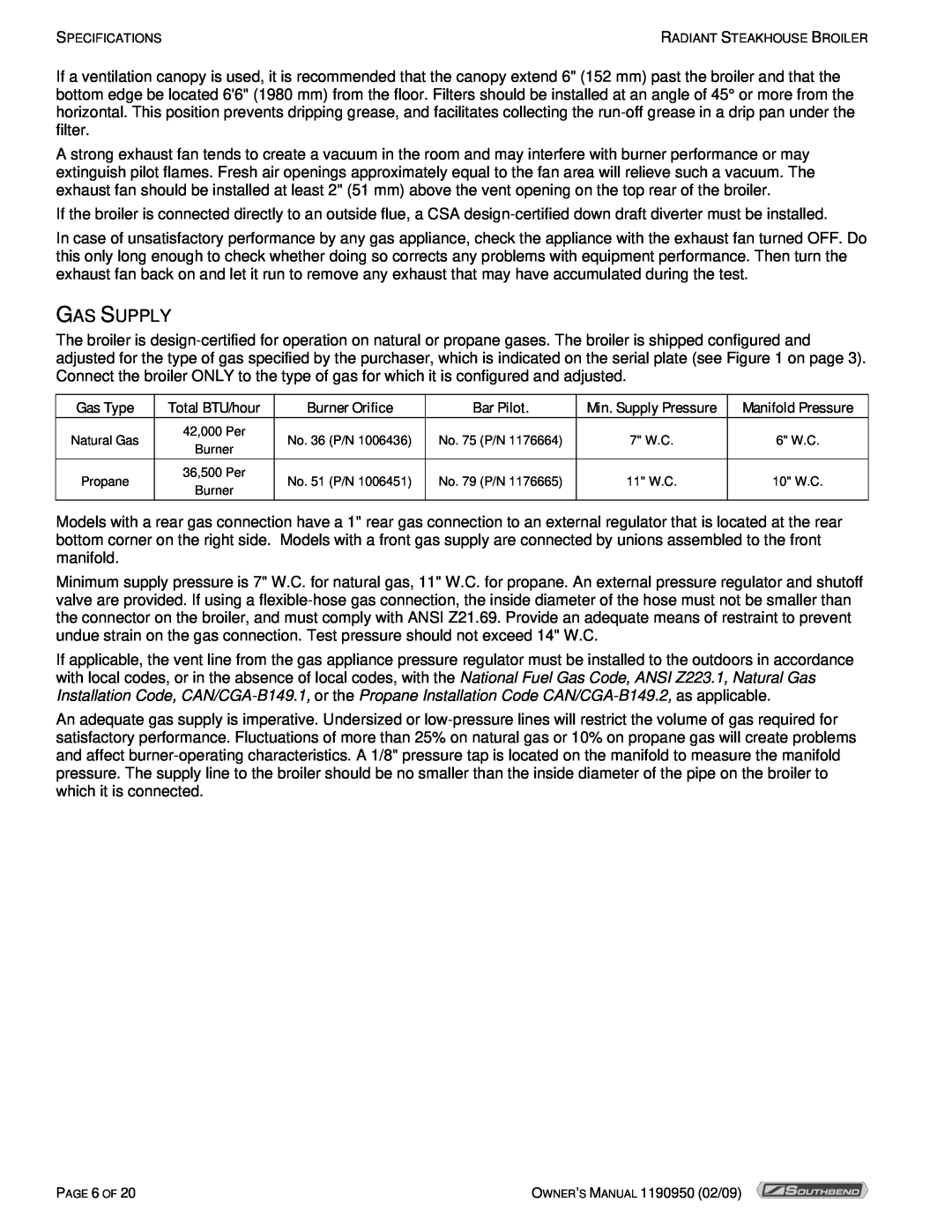

Gas Type | Total BTU/hour | Burner Orifice | Bar Pilot. | |

Natural Gas | 42,000 Per | No. 36 (P/N 1006436) | No. 75 (P/N 1176664) | |

Burner | ||||

|

|

| ||

Propane | 36,500 Per | No. 51 (P/N 1006451) | No. 79 (P/N 1176665) | |

Burner | ||||

|

|

|

Min. Supply Pressure

7" W.C.

11" W.C.

Manifold Pressure

6" W.C.

10" W.C.

Models with a rear gas connection have a 1" rear gas connection to an external regulator that is located at the rear bottom corner on the right side. Models with a front gas supply are connected by unions assembled to the front manifold.

Minimum supply pressure is 7" W.C. for natural gas, 11" W.C. for propane. An external pressure regulator and shutoff valve are provided. If using a

If applicable, the vent line from the gas appliance pressure regulator must be installed to the outdoors in accordance with local codes, or in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1, Natural Gas Installation Code,

An adequate gas supply is imperative. Undersized or

PAGE 6 OF 20 | OWNER’S MANUAL 1190950 (02/09) |