INSTALL TEE FITTING AS CLOSE TO WATER HEATER | INTAKE | |

INTAKE AIR CONNECTION AS POSSIBLE | ||

AIR | ||

FACTORY | ||

PIPING | ||

INTAKE AIR | ||

CONNECTION |

|

FIELD SUPPLIED 3” x 3” x 1/2” TEE WITH HOSE BARB FITTING INSTALLED

CONNECT FIELD

SUPPLIED FLEXIBLE

DRAIN HOSE TO BARB

FITTING AND FORM A

LOOP WATER TRAP IN

DRAIN HOSE

RUN DRAIN HOSE

TO SUITABLE FLOOR

DRAIN SEPARATELY

FROM OTHER

CONDENSATE DRAINS

INTAKE AIR CONDENSATE TEE INSTALLATION

Figure 16

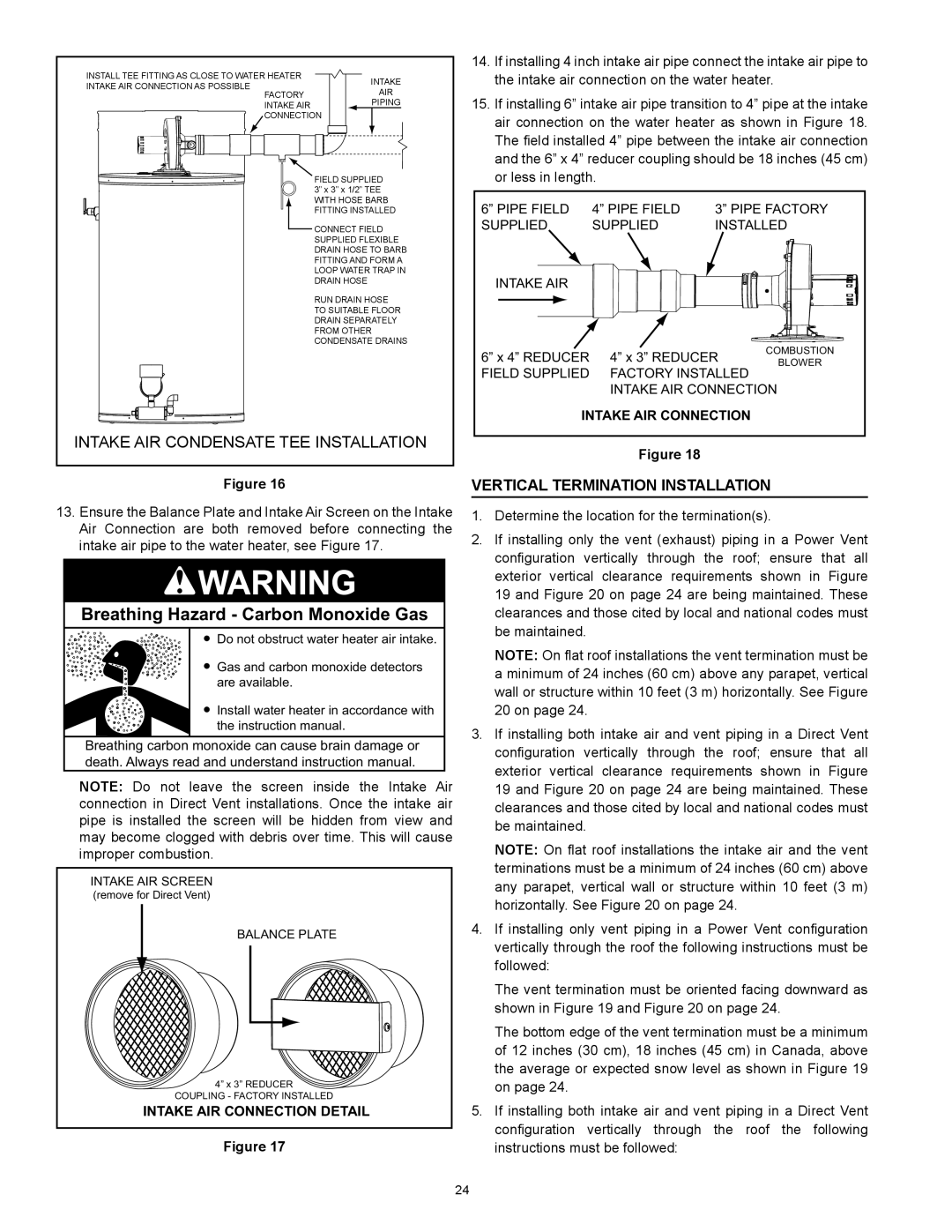

13.Ensure the Balance Plate and Intake Air Screen on the Intake Air Connection are both removed before connecting the intake air pipe to the water heater, see Figure 17.

Breathing Hazard - Carbon Monoxide Gas

![]() Do not obstruct water heater air intake.

Do not obstruct water heater air intake.

![]() Gas and carbon monoxide detectors are available.

Gas and carbon monoxide detectors are available.

![]() Install water heater in accordance with the instruction manual.

Install water heater in accordance with the instruction manual.

Breathing carbon monoxide can cause brain damage or death. Always read and understand instruction manual.

Note: Do not leave the screen inside the Intake Air connection in Direct Vent installations. Once the intake air pipe is installed the screen will be hidden from view and may become clogged with debris over time. This will cause improper combustion.

INTAKE AIR SCREEN |

(remove for Direct Vent) |

BALANCE PLATE |

4” x 3” REDUCER |

COUPLING - FACTORY INSTALLED |

INTAKE AIR CONNECTION DETAIL |

Figure 17

14.If installing 4 inch intake air pipe connect the intake air pipe to the intake air connection on the water heater.

15.If installing 6” intake air pipe transition to 4” pipe at the intake air connection on the water heater as shown in Figure 18. The field installed 4” pipe between the intake air connection and the 6” x 4” reducer coupling should be 18 inches (45 cm) or less in length.

6” PIPE FIELD | 4” PIPE FIELD | 3” PIPE FACTORY | |

SUPPLIED | SUPPLIED | INSTALLED | |

INTAKE AIR |

|

|

|

6” x 4” REDUCER | 4” x 3” REDUCER | COMBUSTION | |

BLOWER | |||

FIELD SUPPLIED | FACTORY INSTALLED |

| |

INTAKE AIR CONNECTION

INTAKE AIR CONNECTION

Figure 18

Vertical Termination Installation

1.Determine the location for the termination(s).

2.If installing only the vent (exhaust) piping in a Power Vent configuration vertically through the roof; ensure that all exterior vertical clearance requirements shown in Figure 19 and Figure 20 on page 24 are being maintained. These clearances and those cited by local and national codes must be maintained.

Note: On flat roof installations the vent termination must be a minimum of 24 inches (60 cm) above any parapet, vertical wall or structure within 10 feet (3 m) horizontally. See Figure 20 on page 24.

3.If installing both intake air and vent piping in a Direct Vent configuration vertically through the roof; ensure that all exterior vertical clearance requirements shown in Figure 19 and Figure 20 on page 24 are being maintained. These clearances and those cited by local and national codes must be maintained.

Note: On flat roof installations the intake air and the vent terminations must be a minimum of 24 inches (60 cm) above any parapet, vertical wall or structure within 10 feet (3 m) horizontally. See Figure 20 on page 24.

4.If installing only vent piping in a Power Vent configuration vertically through the roof the following instructions must be followed:

The vent termination must be oriented facing downward as shown in Figure 19 and Figure 20 on page 24.

The bottom edge of the vent termination must be a minimum of 12 inches (30 cm), 18 inches (45 cm) in Canada, above the average or expected snow level as shown in Figure 19 on page 24.

5.If installing both intake air and vent piping in a Direct Vent configuration vertically through the roof the following instructions must be followed:

24