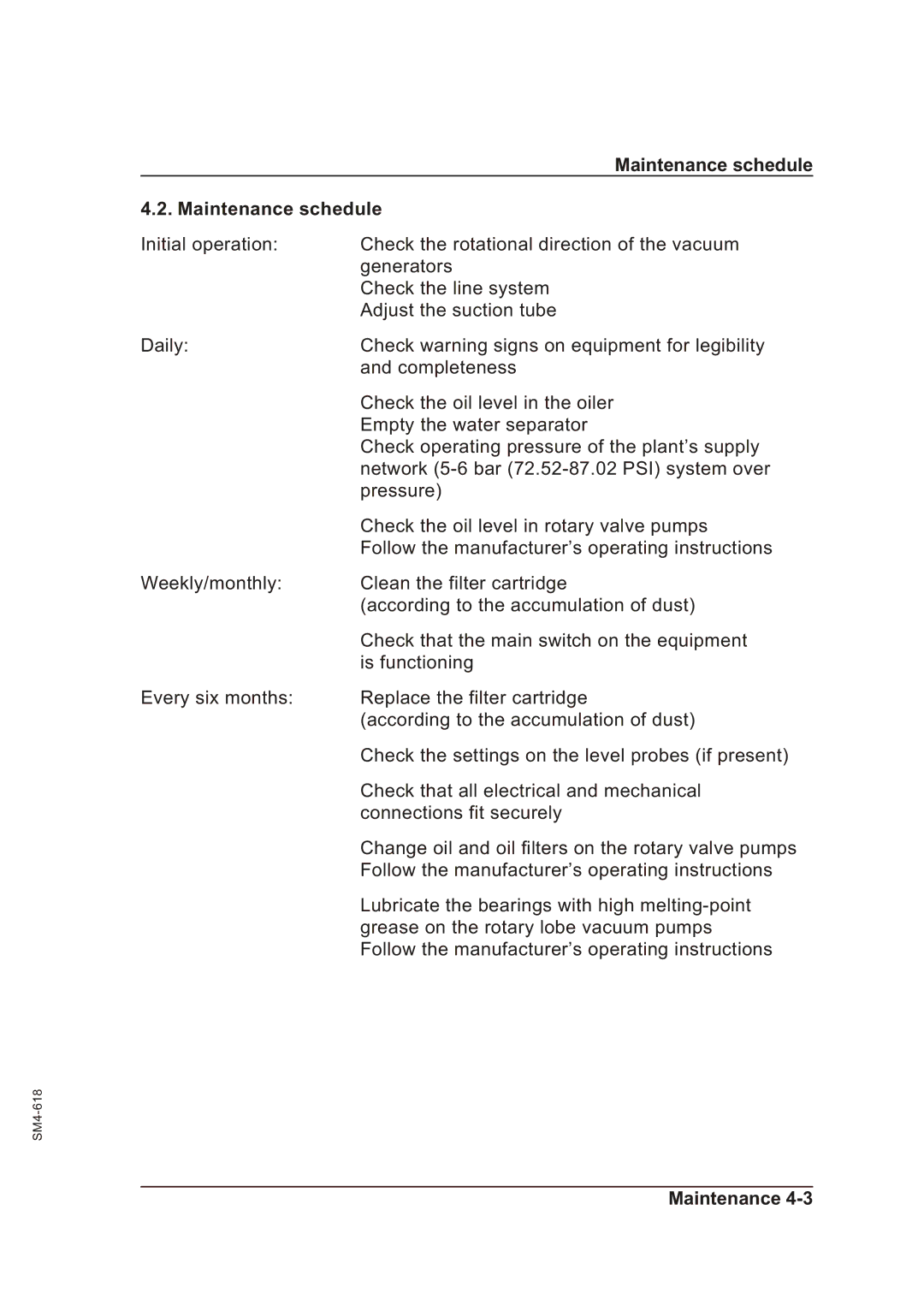

| Maintenance schedule |

4.2. Maintenance schedule | |

Initial operation: | Check the rotational direction of the vacuum |

| generators |

| Check the line system |

| Adjust the suction tube |

Daily: | Check warning signs on equipment for legibility |

| and completeness |

| Check the oil level in the oiler |

| Empty the water separator |

| Check operating pressure of the plant’s supply |

| network |

| pressure) |

| Check the oil level in rotary valve pumps |

| Follow the manufacturer’s operating instructions |

Weekly/monthly: | Clean the filter cartridge |

| (according to the accumulation of dust) |

| Check that the main switch on the equipment |

| is functioning |

Every six months: | Replace the filter cartridge |

(according to the accumulation of dust)

Check the settings on the level probes (if present)

Check that all electrical and mechanical connections fit securely

Change oil and oil filters on the rotary valve pumps

Follow the manufacturer’s operating instructions

Lubricate the bearings with high