ASSEMBLY INSTRUCTIONS/OPERATIONS

the more aggressive the flail configurations, the more coarse the resulting finish and texture.

Many flail configurations are available to meet a wide variety of job applications and surface material specifications. To give additional perspective to each configuration, a rating system of 1 to 10 (10 being highest) has been devised.

FIGURE 6

Star Flail

The star flail is manufactured from high carbon steel that is through hardened for additional service life. It is highly effective for light cleaning or scarifying and delivers a finer surface finish texture. FIGURE 7.

Suggested Applications:

1)Removal of thin coatings and encrusted accumulations.

2)Cleaning concrete and asphaltic surfaces

3)Removing thick material

4)Light scarifying prior to the application of coatings, toppings or sealers.

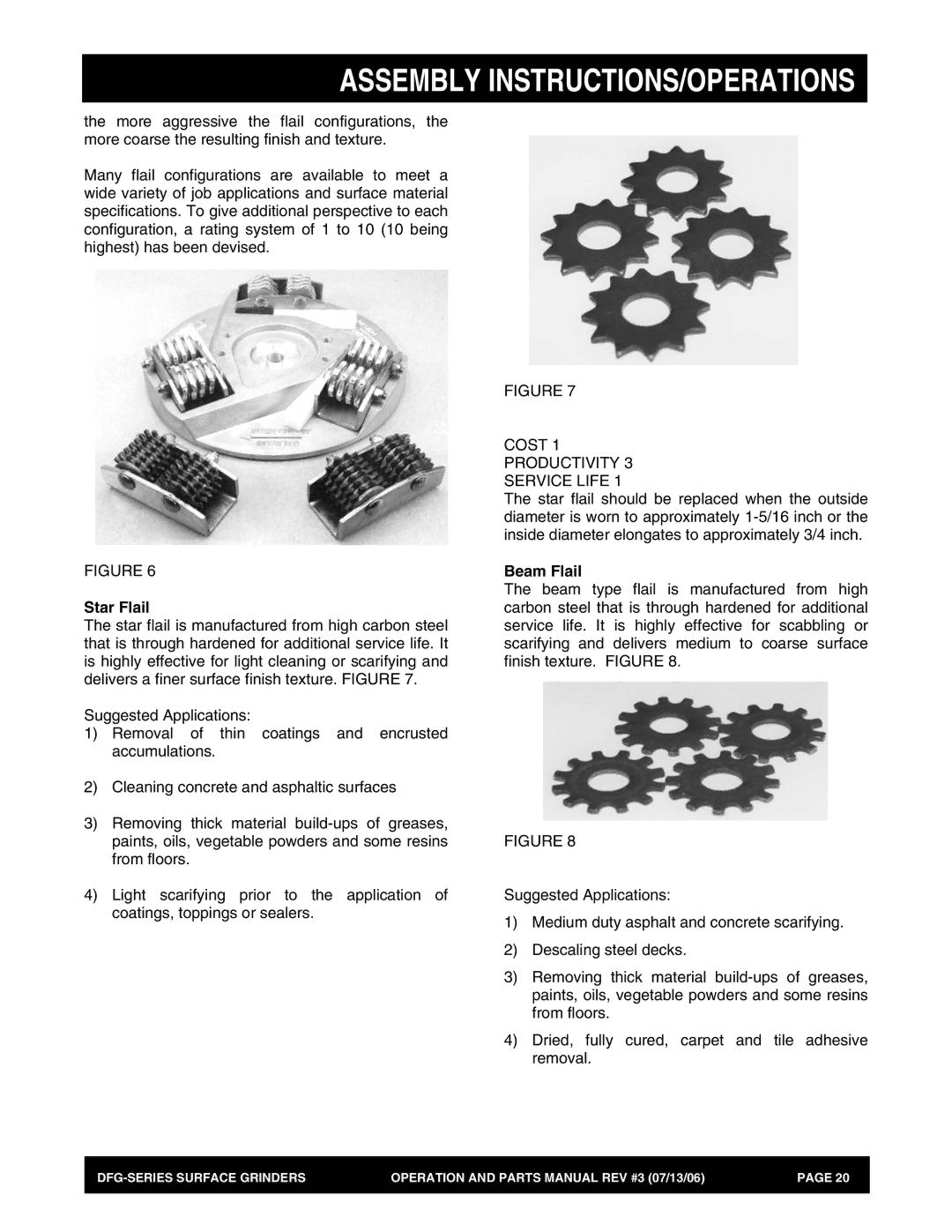

FIGURE 7

COST 1 PRODUCTIVITY 3 SERVICE LIFE 1

The star flail should be replaced when the outside diameter is worn to approximately

Beam Flail

The beam type flail is manufactured from high carbon steel that is through hardened for additional service life. It is highly effective for scabbling or scarifying and delivers medium to coarse surface finish texture. FIGURE 8.

FIGURE 8

Suggested Applications:

1)Medium duty asphalt and concrete scarifying.

2)Descaling steel decks.

3)Removing thick material

4)Dried, fully cured, carpet and tile adhesive removal.

OPERATION AND PARTS MANUAL REV #3 (07/13/06) | PAGE 20 | |

|

|

|