ASSEMBLY INSTRUCTIONS/OPERATIONS

5)Using a hammer, strike the wider side of the mounting wedge with controlled, direct blows to firmly seat the

![]() CAUTION

CAUTION

Do not apply excessive impact force to the mounting wedge to cause splitting. Once the

![]() CAUTION

CAUTION

Improper seating force created by an excessive blow to the mounting wedge will not allow the attachment to properly release from the aluminum disc if direct contact with a foreign object is made. Such occurrence can result in property damage and/or personal injury. The correct seating force for a specific job application is that which is sufficient to retain the attachment, yet still allows it to release from the aluminum disc when direct contact with a foreign object is made.

6)Determine that the

7)Return the SURFACE GRINDER to its normal operating position.

8)If the SURFACE GRINDER is powered by an engine, reconnect the engine spark plug wire. If powered by an electric motor and the machine is to be used immediately, reconnect the extension cord or SURFACE GRINDER to the power source. Determine that the ON/OFF switch located on the operator handle is in the OFF position.

![]() DANGER

DANGER

UNEXPECTED MACHINE START UP CAN RESULT IN PROPERTY DAMAGE AND/OR PERSONAL INJURY.

REMOVING A

FROM THE COUNTERROTATING DISCS.

Application: All Models.

Tools Required:

1 each, Small Hammer

1 each, Drift Punch or small, Pry Bar

![]() DANGER

DANGER

WHEN REMOVING A

1)If the SURFACE GRINDER is powered by an engine, disconnect the spark plug wire. If powered by an electric motor, disconnect the extension cord or SURFACE GRINDER from the power source.

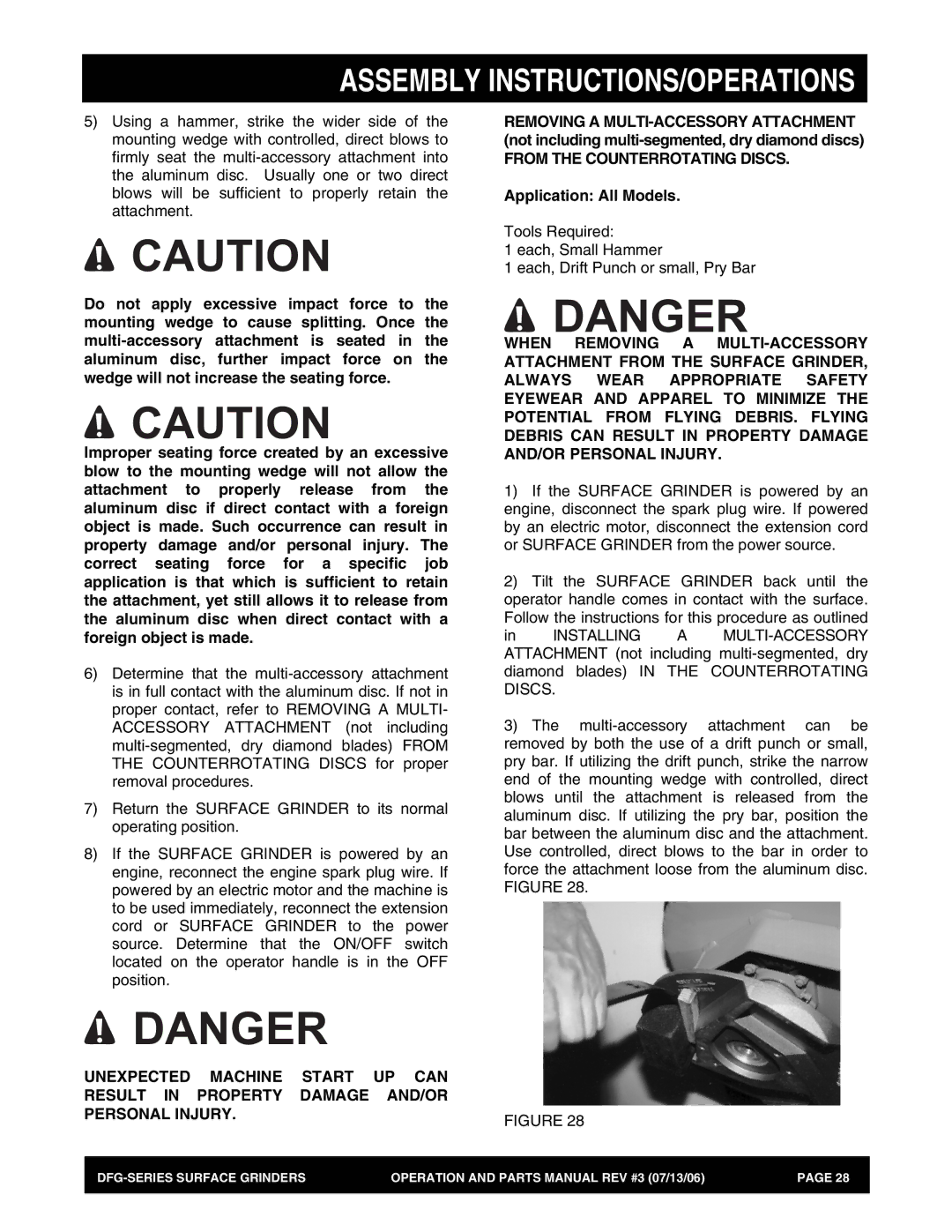

2)Tilt the SURFACE GRINDER back until the operator handle comes in contact with the surface. Follow the instructions for this procedure as outlined

in INSTALLING A

3)The

FIGURE 28

OPERATION AND PARTS MANUAL REV #3 (07/13/06) | PAGE 28 | |

|

|

|