Electric Gasoline

Page

Table of Contents

Table of Contents

Page

Parts Ordering Procedures

Here’s how to get help

Stow Construction Equipment

Page

Page

Operator Instructional Data Sheet

Safety Precautions

Safety Precautions

Operation

Surface Grinder

MAINTENANCE, Repair and Storage

Safety Precautions

Assembly

Removing the Surface Grinder from the Pallet

Application All Models

Installing the SG24-1000 Safety and Dust Shield Assembly KIT

Filling the Engine Crankcase with OIL

Before Starting the Engine

Applications DFG/G Surface Grinder

Filling the DFG/G Series Engine Fuel Tank

Operation

MULTI-ACCESSORY Attachments and Applications

Theory of Operation

Grinding Stones

Scarifier Blocks

Tungsten Carbide Grinding Block

Cost 1 Productivity 3 Service Life

Star Flail

Beam Flail

Cost Productivity Service Life

Cost 1 Productivity 5 Service Life

Pentagonal Flail

Spacer Washer

Scarifier Block Bushing

Wire brushes

SCRAPE-R-TACH Industrial Floor Coatings Removal System

Floor Brushes

Assembly INSTRUCTIONS/OPERATIONS

Follow all safety precautions for the safety solvent

Diamond Segment Block

Assembly INSTRUCTIONS/OPERATIONS

From the Counterrotating Discs

Assembly INSTRUCTIONS/OPERATIONS

Adjusting the Operator Handle HEIGHT. Application All Models

Assembly INSTRUCTIONS/OPERATIONS

Assembly INSTRUCTIONS/OPERATIONS

Operating the Surface Grinder on the Jobsite

Fiure

Result in Property Damage AND/OR Personal Injury

Assembly INSTRUCTIONS/OPERATIONS

Stopping the DFG/G Series Gasoline Powered Surface Grinder

Application All Models Early Age Grinding

Definitions of floor flatness and levelness

Defined Versus Random Traffic Patterns

How to Define Surface Regularity

TR 34 tolerances for defined traffic floors

Assembly INSTRUCTIONS/OPERATIONS

MAINTENANCE/SERVICE

Maintenance/Service

Preventative Maintenance Check LIST. Application All Models

Observe all applicable safety precautions for the solvent

MAINTENANCE/SERVICE

Checking V-BELT Tension and Alignment

MAINTENANCE/SERVICE

Lubrication Requirements

Engine Service

Electric Motor Service

Troubleshooting

Troubleshooting

Uneven MULTI-ACCESSORY Attachment Wear

Operational PROBLEMS. Application All Models

Accelerated V-BELT Wear

Accelerated Bearing Wear AND/OR Failure

Storage

Storage

Vacuum Cleaner Connection Diameter

Specifications

Maximum Grinding Width

Typical Operator Handle Height

Page

Part Name

Remarks

Xxxxx only Not Used on

Suggested Spare Parts

Units Gasoline Engine Units Electric Motor Model

Qty Description

Operator Handle ASSY. Electric

Operator Handle ASSY. Electric

HP Motor only

HANDLE, Operator Universal

CABLE, Long

CABLE, Short

Operator Handle ASSY. Gasoline

Operator Handle ASSY. Gasoline

KNOB, Throttle Control

CABLE, Throttle

QTY Remarks

LEVER, Throttle CONTROL, W/CABLE & Knob

Electric Motor Assy

Electric Motor Assy

HP 50 HZ Motor

MOUNT, Electric Motor

SCREW, CAP 5/16-18 UNC X 1 Plated

WASHER, Flat 5/16, Plated

Gasoline Engine Assy

Gasoline Engine Assy

MOUNT, Gasoline Engine

ENGINE, Honda 11 H.P

CLUTCH, Pulley Assy

CAP, OIL Drain

Wheel Assy

Wheel Assy

Wheel

ARM, Swing

AXLE, Plated

WASHER, Flat ¾ Plated

Transmission Assy

Transmission Assy

COVER, Transmission

FRAME, Main

BEARING, Flange

WASHER, Lock 5/16 Plated

Head Assy

Head Assy

DISC, MULTI- Accessory RH

DISC, MULTI- Accessory LH

BAR, Mounting

DISC, Mounting

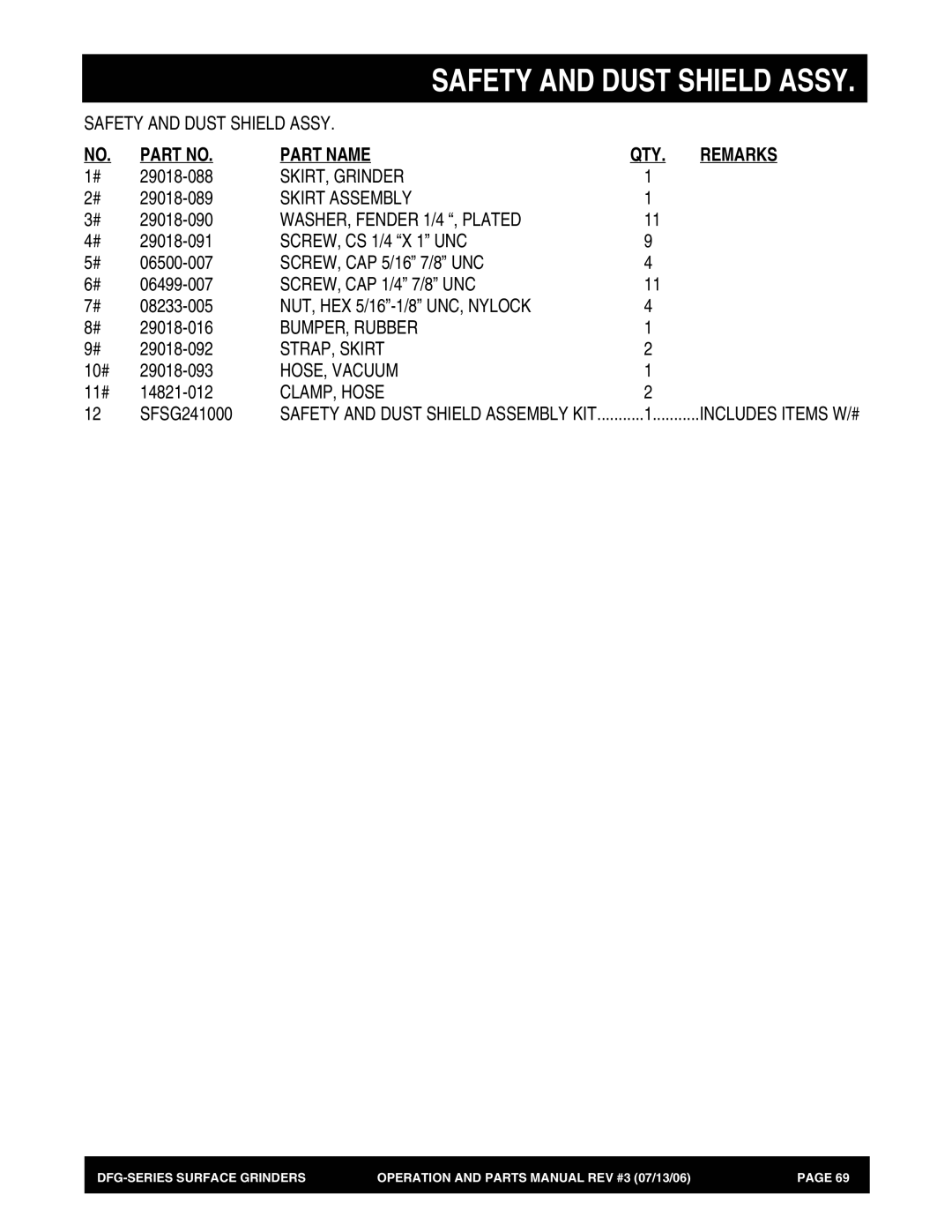

Safety and Dust Shield Assy

Safety and Dust Shield Assy

SKIRT, Grinder

Skirt Assembly

WASHER, Fender 1/4 , Plated

STRAP, Skirt

Scarifier Assy

Scarifier Assy

Bushing

Housing

NUT, HEX 3/8 UNC, Nylock Plated

WEDGE, Plastic

SCRAPE-R-TACH Assy

MOUNT, Rubber

HOLDER, Insert

Spacer

INSERT, Tungsten Carbide

Grinding Block Assy

Ring

Block

Aggress Grinding

General Purpose

Decals

Decals

DECAL, Warning

Decals Part Name QTY Remarks

DECAL, Operation

DECAL, Throttle Sfdclsdp DECAL, Stow Large

PRICING, Rebates Specifications

Special Expediting Service

Payment Terms

Freight Policy

Page

FAX

Heres HOW to GET Help