ASSEMBLY INSTRUCTIONS/OPERATIONS

thicknesses, the required number of components can be assembled on a block in a minimum amount of time.

![]() DANGER

DANGER

USE ONLY FACTORY SUPPLIED SPACER WASHERS ON THE SCARIFIER BLOCK. OTHER WASHER TYPES AND/OR CONFIGURATIONS CAN PRODUCE ABNORMAL WEAR AND ELONGATION, RESULTING IN COMPLETE SEPARATION FROM THE SCARIFIER BLOCK. INADVERTENT SPACER WASHER SEPARATION CAN LEAD TO PROPERTY DAMAGE AND/OR PERSONAL INJURY.

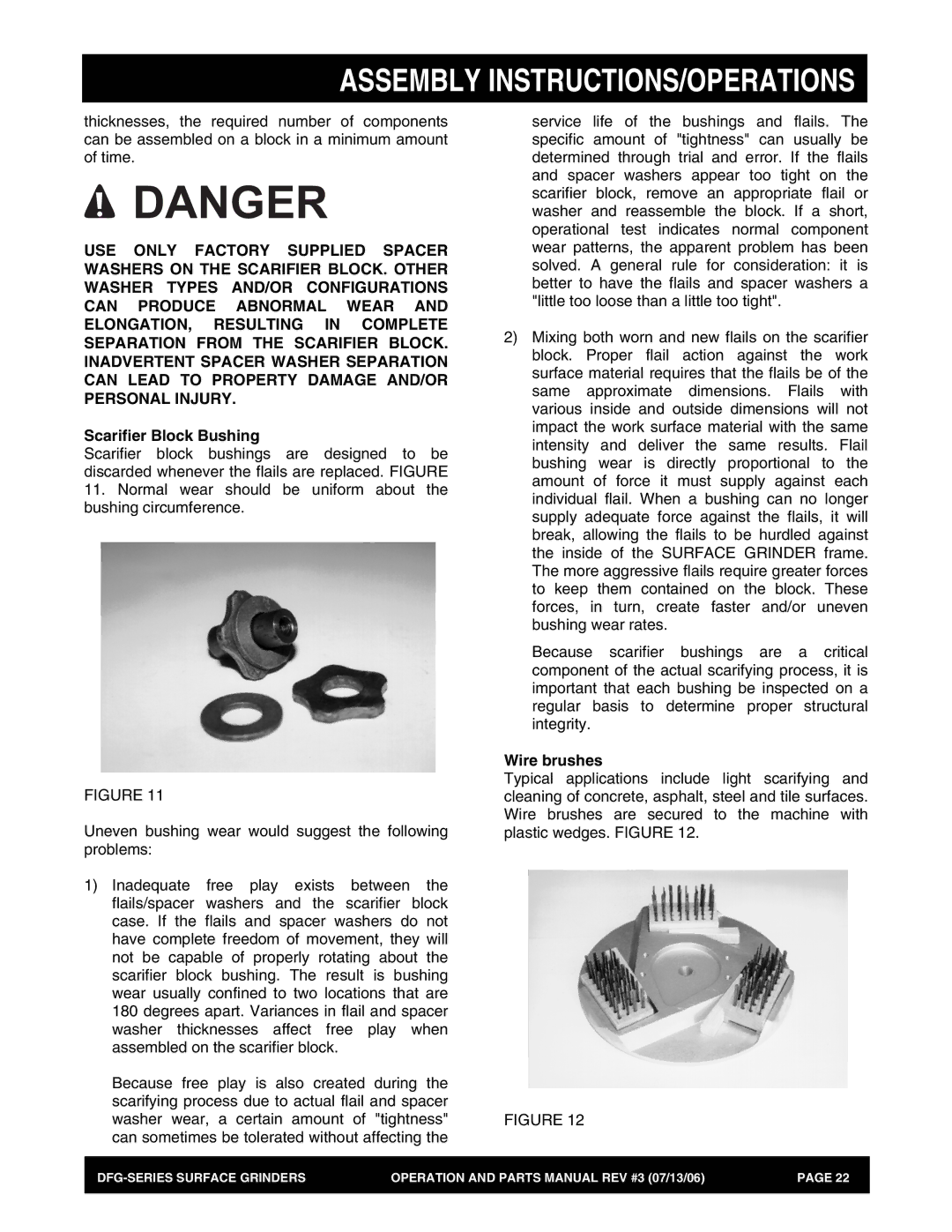

Scarifier Block Bushing

Scarifier block bushings are designed to be discarded whenever the flails are replaced. FIGURE

11.Normal wear should be uniform about the bushing circumference.

FIGURE 11

Uneven bushing wear would suggest the following problems:

1)Inadequate free play exists between the flails/spacer washers and the scarifier block case. If the flails and spacer washers do not have complete freedom of movement, they will not be capable of properly rotating about the scarifier block bushing. The result is bushing wear usually confined to two locations that are 180 degrees apart. Variances in flail and spacer washer thicknesses affect free play when assembled on the scarifier block.

Because free play is also created during the scarifying process due to actual flail and spacer washer wear, a certain amount of "tightness" can sometimes be tolerated without affecting the

service life of the bushings and flails. The specific amount of "tightness" can usually be determined through trial and error. If the flails and spacer washers appear too tight on the scarifier block, remove an appropriate flail or washer and reassemble the block. If a short, operational test indicates normal component wear patterns, the apparent problem has been solved. A general rule for consideration: it is better to have the flails and spacer washers a "little too loose than a little too tight".

2)Mixing both worn and new flails on the scarifier block. Proper flail action against the work surface material requires that the flails be of the same approximate dimensions. Flails with various inside and outside dimensions will not impact the work surface material with the same intensity and deliver the same results. Flail bushing wear is directly proportional to the amount of force it must supply against each individual flail. When a bushing can no longer supply adequate force against the flails, it will break, allowing the flails to be hurdled against the inside of the SURFACE GRINDER frame. The more aggressive flails require greater forces to keep them contained on the block. These forces, in turn, create faster and/or uneven bushing wear rates.

Because scarifier bushings are a critical component of the actual scarifying process, it is important that each bushing be inspected on a regular basis to determine proper structural integrity.

Wire brushes

Typical applications include light scarifying and cleaning of concrete, asphalt, steel and tile surfaces. Wire brushes are secured to the machine with plastic wedges. FIGURE 12.

FIGURE 12

OPERATION AND PARTS MANUAL REV #3 (07/13/06) | PAGE 22 | |

|

|

|